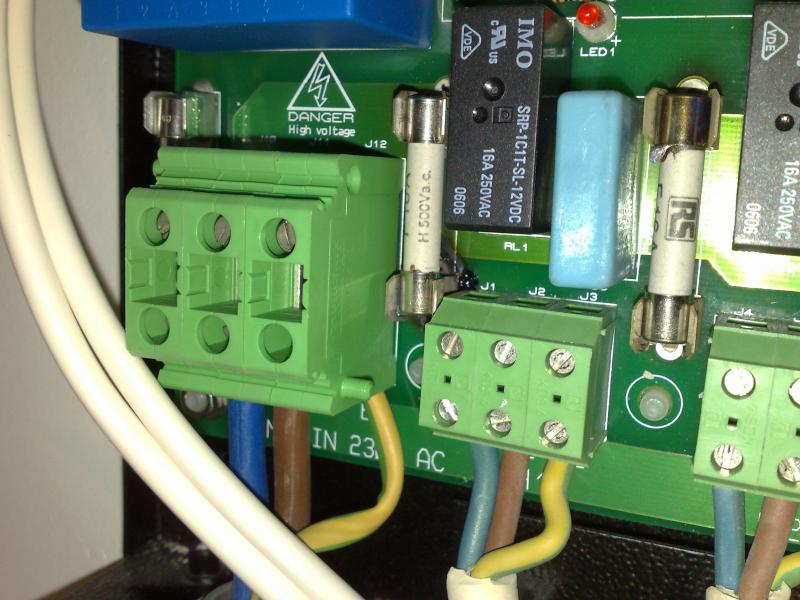

Has anyone had any experiance of the pcb on this equipment charring near the fuse clips. The fuse protects a heating element which draws 14.3A. But as far as I can tell the fuseclips are only rated for 10A, the manufacturer understandbly denies any design fault or liability and I quote "This problem only happens in areas of the country where there is low voltage as this causes increased current on the fuseholders".

Opinions welcome

Martin

Opinions welcome

Martin