We’ve had this boiler for 4 years and it’s been ok, but it now has developed 2 problems.

1. There is no hot water at all.

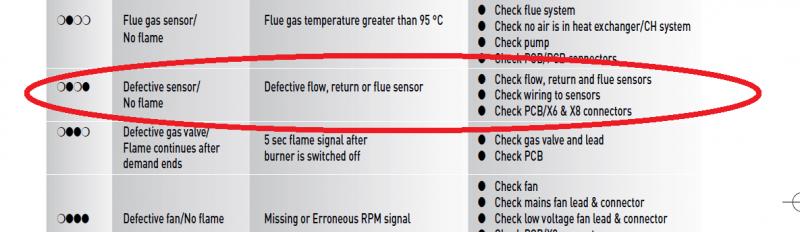

2. When the central heating is on, it fires up and runs for about 2 minutes then locks out. If you leave it alone for about 10 minutes it eventually fires up again and does exactly the same thing again.

Solutions I've tried so far.

1. I've removed the plate heat exchanger and filter and cleaned them out. There was hardly any sludge in there to be honest.

2. I’ve changed the hot water flow turbine for a new one, but there is still no hot water. Even if I put the boiler in comfort mode it never fires up. In comfort mode the boiler should fire up occasionally, so there is a bit of immediate hot water, it doesn't do this anymore in comfort mode.

3. I've read on here (and other forums) that the something called the diverter valve motor can fail on these boilers. However by using a small mirror, I can see the diverter valve moving when the central heating is switched on. However when I turn on the hot water, it doesn't move back to the hot water position (It was actually this that lead me to think that the flow turbine was faulty.) However if you turn the central heating off and hot water off and wait for a few minutes the diverter valve moves back to the hot water position itself. This suggests to me the diverter valve is probably working ok.

Has anyone got any other ideas of what could cause these 2 faults? I am wondering if the new flow turbine I've bought could also be faulty, but my gut feeling is telling both are ok. Is there any way of testing them with a multimeter so I can confirm they are both faulty or not?

But regardless of whether the flow turbines are faulty or not, it doesn't explain why the boiler doesn't fire up occasionally in comfort mode (for that bit of instant hot water).

Thanks in advance

1. There is no hot water at all.

2. When the central heating is on, it fires up and runs for about 2 minutes then locks out. If you leave it alone for about 10 minutes it eventually fires up again and does exactly the same thing again.

Solutions I've tried so far.

1. I've removed the plate heat exchanger and filter and cleaned them out. There was hardly any sludge in there to be honest.

2. I’ve changed the hot water flow turbine for a new one, but there is still no hot water. Even if I put the boiler in comfort mode it never fires up. In comfort mode the boiler should fire up occasionally, so there is a bit of immediate hot water, it doesn't do this anymore in comfort mode.

3. I've read on here (and other forums) that the something called the diverter valve motor can fail on these boilers. However by using a small mirror, I can see the diverter valve moving when the central heating is switched on. However when I turn on the hot water, it doesn't move back to the hot water position (It was actually this that lead me to think that the flow turbine was faulty.) However if you turn the central heating off and hot water off and wait for a few minutes the diverter valve moves back to the hot water position itself. This suggests to me the diverter valve is probably working ok.

Has anyone got any other ideas of what could cause these 2 faults? I am wondering if the new flow turbine I've bought could also be faulty, but my gut feeling is telling both are ok. Is there any way of testing them with a multimeter so I can confirm they are both faulty or not?

But regardless of whether the flow turbines are faulty or not, it doesn't explain why the boiler doesn't fire up occasionally in comfort mode (for that bit of instant hot water).

Thanks in advance