The pump was installed with the flow arrows pointing up, the flow comes in at the bottom and goes out at top onto the CH and HW motorised valves. You can see from the photograph the Grundfos label is the correct way up.

The label can be rotated to any orientation that you choose!

Most would have advised using a 15-60 pump on a microbore system.

Tony

As stated in the quote the arrows (cast in the body of the pump) were pointing up, to me this means the direction of flow is up and the also meant the label was in the correct orientation. The rotaion of the pump was checked and was found to be in the correct direction according to Grundfos.

With the flow coming in at the bottom and going out at the top (arrows pointing UP), the flow from the boiler into the system would be the correct direction.

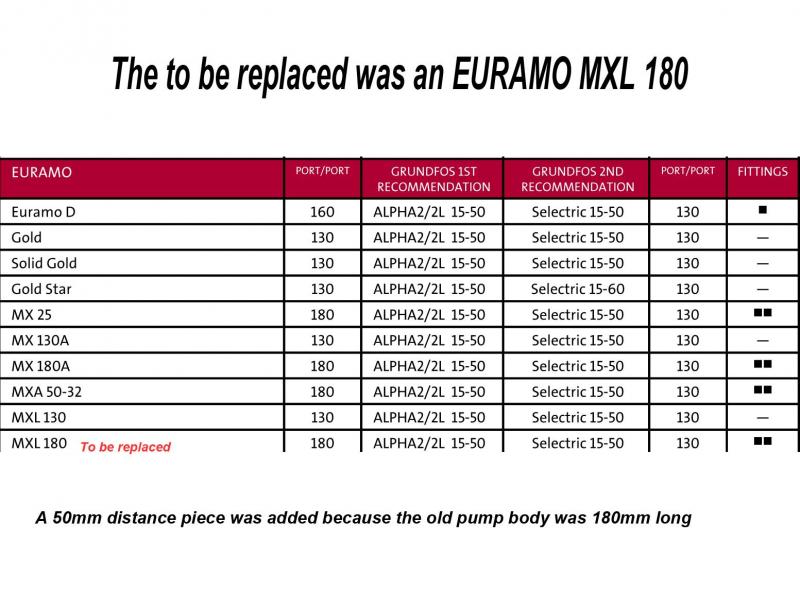

The 15-50 pump was the direct replacement recommended by Grundfos and was confirmed by the local pump supplier.

Please see selection chart picture for more information.