OK, so the birth of my first child has meant that my office has been turned into a nursery and I am to be banished to the only space available - the detached garage!

It's as cold and damp as you would expect for a single skinned brick garage in the UK, but essentially water tight. The advantage is there is plenty of space - I can easily sacrifice a 3m x 2m footprint, and still have room for my workshop and a car.

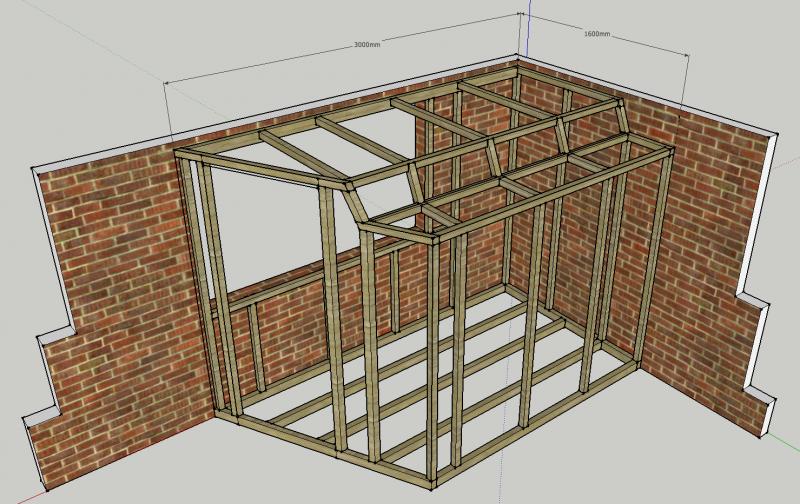

I plan to construct a timber 'box' in one corner, up against the window (double glazed, rescued from a previous house refurb). I want this to be free standing, and completely free from support from the fabric of the garage as I expect I might have to do some repairs to the garage roof in the next 2 years or so.

I will use celotex type insulation boards in the roof, walls and floor of the structure between the studs, clad on the outside with 12mm OSB, 18mm WBP ply on the floor and plastered on the inside.

My question is how do I ensure sufficient damp proofing and ventilation between the walls (brick) and floor (concrete, no DPC) of the garage that will be butting up against this wooden 'box'? My thoughts at the moment run to wrapping the outside of the structure that are against the walls in vapour barrier, and laying a thick polythene sheet under the structure. However, I am aware that a certain amount of ventilation around a structure like this might be a good idea to prevent decay to the brickwork etc...?

Any help would be appreciated!

It's as cold and damp as you would expect for a single skinned brick garage in the UK, but essentially water tight. The advantage is there is plenty of space - I can easily sacrifice a 3m x 2m footprint, and still have room for my workshop and a car.

I plan to construct a timber 'box' in one corner, up against the window (double glazed, rescued from a previous house refurb). I want this to be free standing, and completely free from support from the fabric of the garage as I expect I might have to do some repairs to the garage roof in the next 2 years or so.

I will use celotex type insulation boards in the roof, walls and floor of the structure between the studs, clad on the outside with 12mm OSB, 18mm WBP ply on the floor and plastered on the inside.

My question is how do I ensure sufficient damp proofing and ventilation between the walls (brick) and floor (concrete, no DPC) of the garage that will be butting up against this wooden 'box'? My thoughts at the moment run to wrapping the outside of the structure that are against the walls in vapour barrier, and laying a thick polythene sheet under the structure. However, I am aware that a certain amount of ventilation around a structure like this might be a good idea to prevent decay to the brickwork etc...?

Any help would be appreciated!