Hi guys, looking to do a small amount of Tape and Jointing in a bedroom.

A quick few questions.

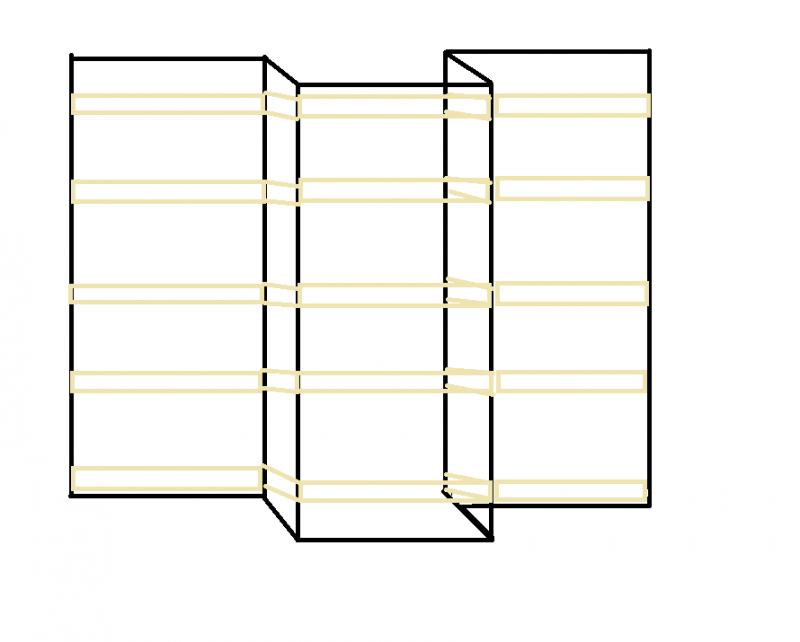

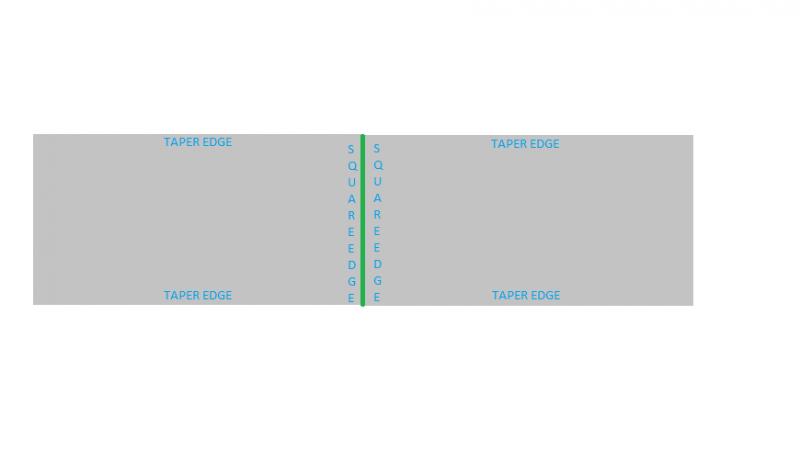

I will be using tapered edge boards, but there will obviously be joins where a tapered edge meets a square edge where a board has being cut, I was wondering if I still go the same way about taping and jointing this join? As I would have thought it would be harder to feather out?

Also,

Should I make tapers meet in the internal corners?

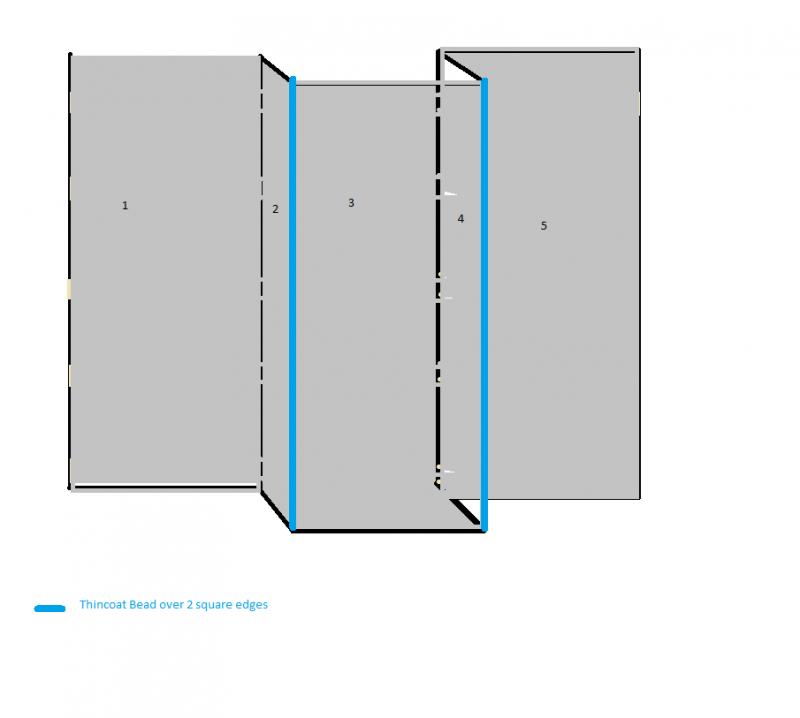

Should I use thin coat beat for the internal corners or scrim?

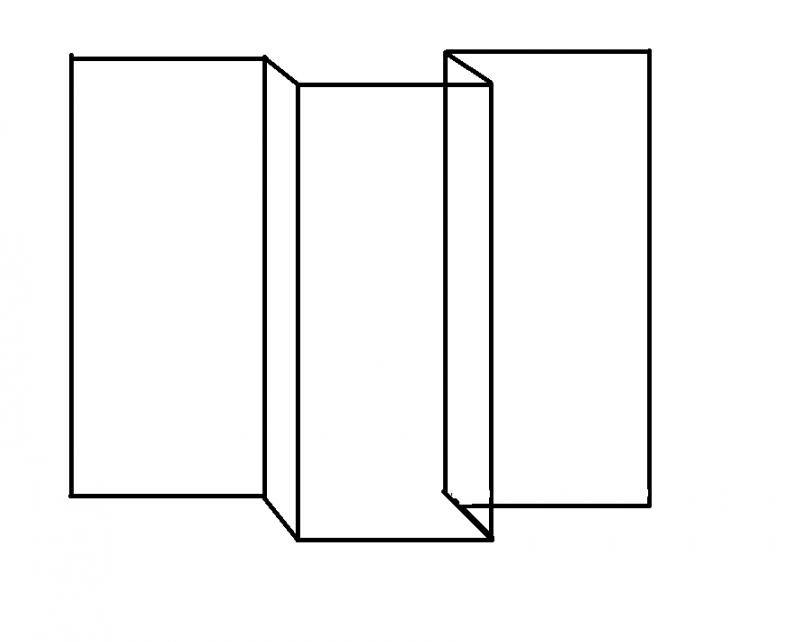

Can I have square edges for external corners and use thin coat beads?

Any advice much appreciated

Cheers

Adam

A quick few questions.

I will be using tapered edge boards, but there will obviously be joins where a tapered edge meets a square edge where a board has being cut, I was wondering if I still go the same way about taping and jointing this join? As I would have thought it would be harder to feather out?

Also,

Should I make tapers meet in the internal corners?

Should I use thin coat beat for the internal corners or scrim?

Can I have square edges for external corners and use thin coat beads?

Any advice much appreciated

Cheers

Adam