We are about to accept a quote for installing two 2 x Vaillant Eco Tec Plus 630 system boilers to replace our failing Ideal Concord CXS/SD 40 which has had more parts than triggers broom has had heads!!

I believe most tandem boiler setups are controlled by a single timeswitch/controller and both boilers fire at the same time and work in parallel. This is fine during cold spells where the full output of both boilers is required, however it's a bit wasteful during warm spells when one boiler would be more than adequate. I am looking to get the most out of these boilers in terms of efficiency and I believe a Boiler Sequencer helps with this.

Most are very expensive with the cheapest I can find at nearly £300 by Warmworld. The only thing with this sequencer is it alternates the lead and lag boiler at a preset time. This means that both boilers effectively carry and equal duty cycle over their lifetime. However they then potentially both wear out at the same time. I believe another option is to set the flow temperature higher on one of the two boilers during the year and then swap this round at service time. I think I have that correct??

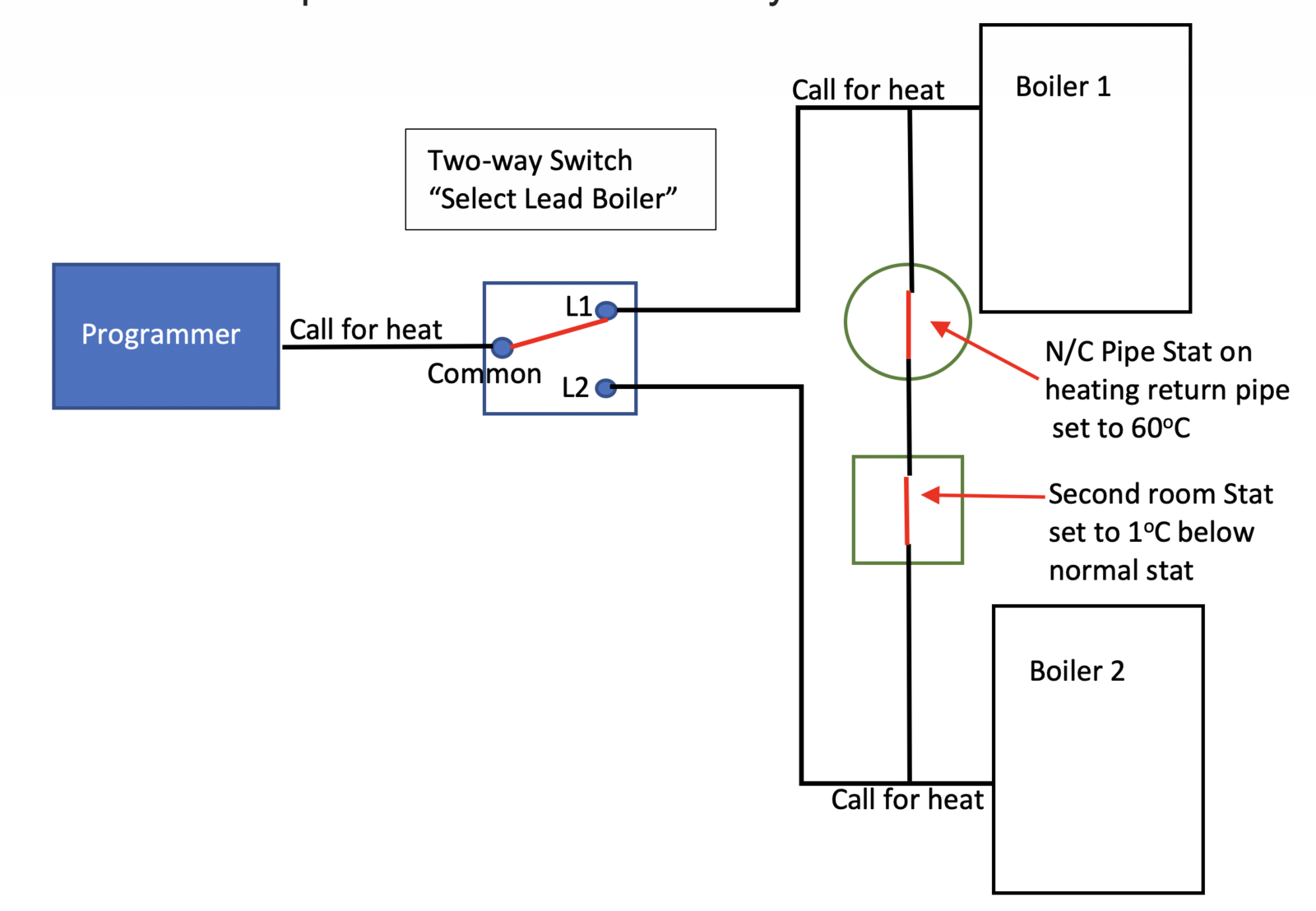

One other option I have seen is a diy setup designed by Tony Bryer on Home Owners Forum , his setup is to use a two way switch as picture below as described here

The ordinary controller goes into the common of a two-way switch (select lead boiler) with L1 and L2 going to the call for heat on each boiler. Between L1 and L2 there is a connection which goes through a room stat (a CM67 on our system) set 1/2 degree or so lower than the main one, and a pipe stat (normally closed, but set to open at about 60C) on the return from the heating.

So from cold, both these stats are closed so L1 and L2 are connected and both boilers run. If the desired temperature is all but there, the second boiler drops out, and this also happens if the return temp reaches 60 (i.e the rads are not getting rid of the heat fast enough).

A pipe stat is also used in the Warmworld sequencer but the above DIY system is manual with the ability at service time to flick the switch to the other boiler which then acts as lead boiler for the next year which seems a neat alternative.

I would appreciate any thoughts or views on boiler sequencers or configurations that provide the best efficiency. I have looked for Vaillant sequencers but can't find anything in their boiler controls section. I believe some system boilers are designed to be linked together internally when used in Tandem which handles this function but not sure of Vaillant.

.

I believe most tandem boiler setups are controlled by a single timeswitch/controller and both boilers fire at the same time and work in parallel. This is fine during cold spells where the full output of both boilers is required, however it's a bit wasteful during warm spells when one boiler would be more than adequate. I am looking to get the most out of these boilers in terms of efficiency and I believe a Boiler Sequencer helps with this.

Most are very expensive with the cheapest I can find at nearly £300 by Warmworld. The only thing with this sequencer is it alternates the lead and lag boiler at a preset time. This means that both boilers effectively carry and equal duty cycle over their lifetime. However they then potentially both wear out at the same time. I believe another option is to set the flow temperature higher on one of the two boilers during the year and then swap this round at service time. I think I have that correct??

One other option I have seen is a diy setup designed by Tony Bryer on Home Owners Forum , his setup is to use a two way switch as picture below as described here

The ordinary controller goes into the common of a two-way switch (select lead boiler) with L1 and L2 going to the call for heat on each boiler. Between L1 and L2 there is a connection which goes through a room stat (a CM67 on our system) set 1/2 degree or so lower than the main one, and a pipe stat (normally closed, but set to open at about 60C) on the return from the heating.

So from cold, both these stats are closed so L1 and L2 are connected and both boilers run. If the desired temperature is all but there, the second boiler drops out, and this also happens if the return temp reaches 60 (i.e the rads are not getting rid of the heat fast enough).

A pipe stat is also used in the Warmworld sequencer but the above DIY system is manual with the ability at service time to flick the switch to the other boiler which then acts as lead boiler for the next year which seems a neat alternative.

I would appreciate any thoughts or views on boiler sequencers or configurations that provide the best efficiency. I have looked for Vaillant sequencers but can't find anything in their boiler controls section. I believe some system boilers are designed to be linked together internally when used in Tandem which handles this function but not sure of Vaillant.

.