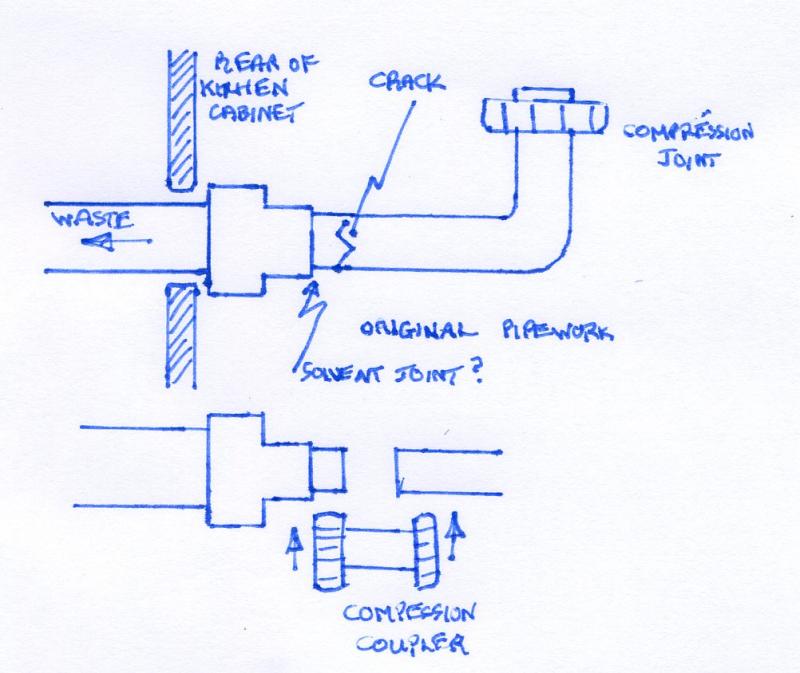

A kitchen sink 40mm waste pipe has cracked close to the point at which is disappears behind the cabinet rear wall. I have repaired this by cutting the pipe and joining the two ends with a compression fit coupler, However, the end that disappears behind the cabinet is close to a junction and will only insert into the coupling a short way.

It seems to be holding but I am concerned that it could too easily be pulled out from the coupler. Is it possible to buy coupling pipe slightly smaller in diameter than the existing pipe so that a short length could be pushed into both ends and fixed with solvent? Thus, the two ends would be bridged by a short section of slightly smaller pipe.

It seems to be holding but I am concerned that it could too easily be pulled out from the coupler. Is it possible to buy coupling pipe slightly smaller in diameter than the existing pipe so that a short length could be pushed into both ends and fixed with solvent? Thus, the two ends would be bridged by a short section of slightly smaller pipe.