Hi All,

I need a garage door for a single garage that has been converted into a room. My use of the room is going to be a little odd - essentially I want to use it to house my motorcycle, tools etc, but also have it as a study. I therefore want the following:

What I really want, is an externally folding hangar style door (like this) but I cant find anyone in the UK that makes them. Does anyone know where I might be able to source such a thing?

Alternatively, I consider myself an expert DIYer and I would consider making it myself. There are only a few concerns I have:

1. How to counterbalance the door properly (where could I get such a unit.

2. Where to buy a control unit for a garage door (which I would probably connect to some form of winch, and some electric drop bolts for security)

3. Are there any building regs against making your own doors? The room is still listed as a garage and it still retains a double locked fire door to the house and fire resistant ceiling & walls.

Thanks for your help,

Jon

I need a garage door for a single garage that has been converted into a room. My use of the room is going to be a little odd - essentially I want to use it to house my motorcycle, tools etc, but also have it as a study. I therefore want the following:

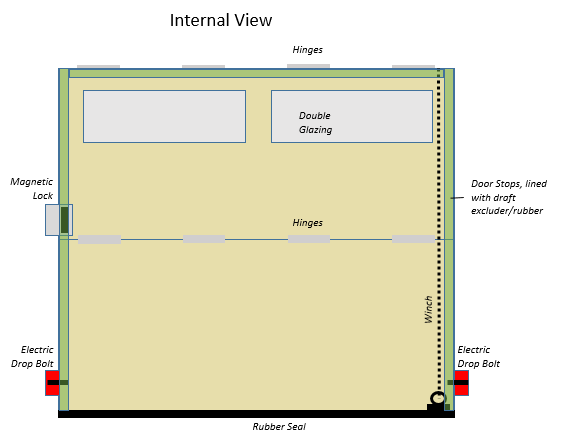

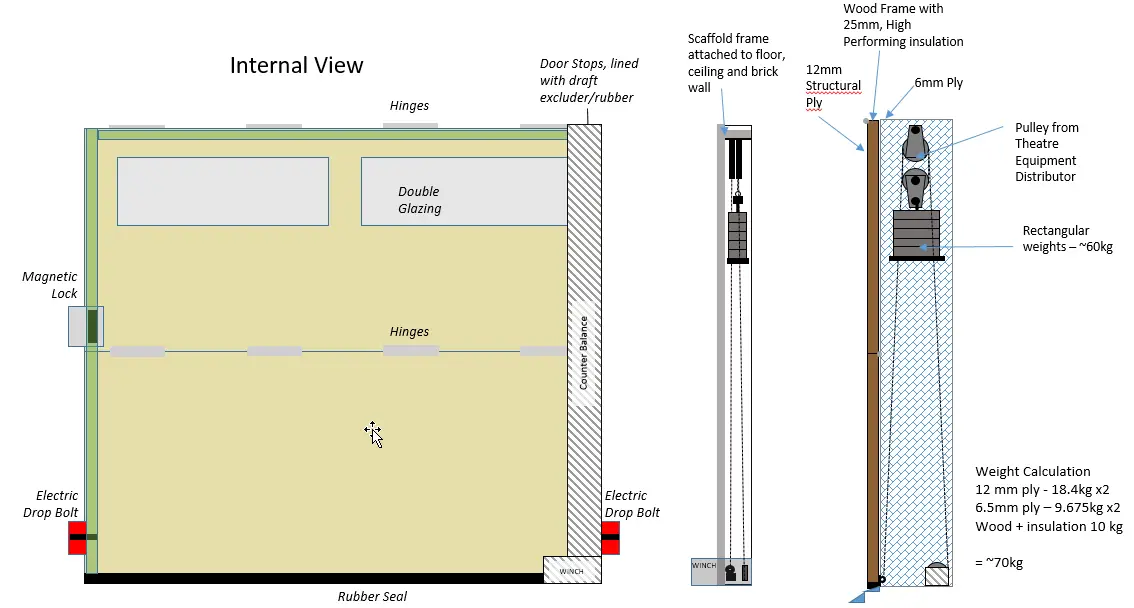

- To use an absolute minimum of ceiling space (preferably none) so that I can hang items from the ceiling.

- To use a minimum of wall space when the door opens / closes (preferably only a small amount to support the automatic opener/closer & counterbalance mechanism)

- To have a door with reasonable insulative properties to keep me warm.

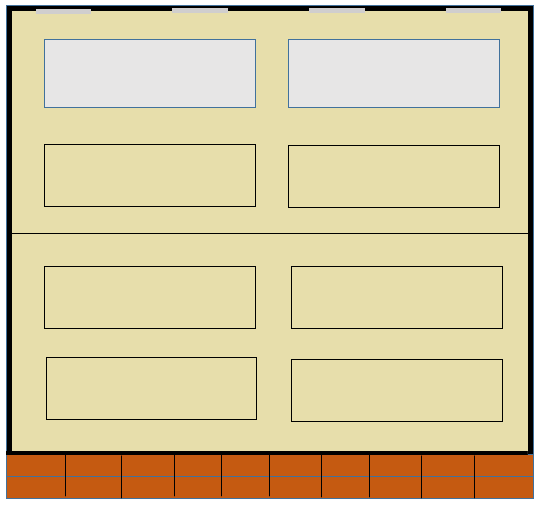

- To include 2 pains of double glazed glass to let light into the room

- Ideally to be automatic (should have not a must)

- Not to obstruct the left or right outside of the property when the door is open (as I need to angle the motorcycle so that I can ride past the car on the driveway)

What I really want, is an externally folding hangar style door (like this) but I cant find anyone in the UK that makes them. Does anyone know where I might be able to source such a thing?

Alternatively, I consider myself an expert DIYer and I would consider making it myself. There are only a few concerns I have:

1. How to counterbalance the door properly (where could I get such a unit.

2. Where to buy a control unit for a garage door (which I would probably connect to some form of winch, and some electric drop bolts for security)

3. Are there any building regs against making your own doors? The room is still listed as a garage and it still retains a double locked fire door to the house and fire resistant ceiling & walls.

Thanks for your help,

Jon