Is it true that the red stop buttons are limited to 13A and hence you need a contactor for higher current supplies?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Using a contactor with emergency stop button

- Thread starter buns

- Start date

Sponsored Links

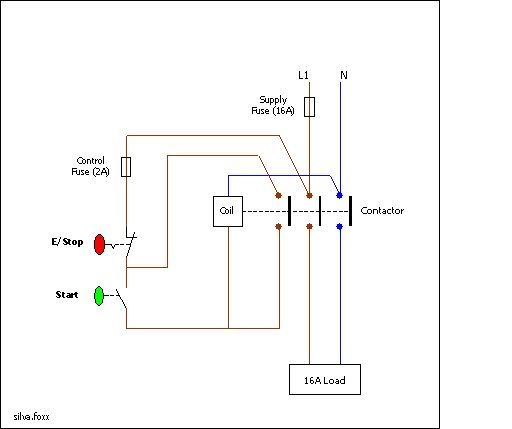

The switch contact will have a rating on it, some are only 10A. But that aside, an emergency stop circuit should incorporate a contactor so that pressing the e stop will drop the contactor out and resetting the e stop will not power the contactor up again unless the start button is also pressed. What is the application?

supply to a server rack is the application. What I've got is a 16A supply through a contactor with the stop button stopping the contactor. The question posed to me was 'why not just put the supply through the stop button?' hence the above question.

Your reply gives me another question though, the supply to the coil (through fused spur) comes from the supply side of the contactor so resetting the stop button does put the power back on. Is this not normal?

Your reply gives me another question though, the supply to the coil (through fused spur) comes from the supply side of the contactor so resetting the stop button does put the power back on. Is this not normal?

B

breezer

so resetting the stop button does put the power back on. Is this not normal?

no.

The supply to the coil should also go through the contactor, so that when the contactor is not in there is no connection to the coil.

a start button (or go) is connected from live to coil, when pressed it pulls in the contactor and it (the contactor) stays in until a red stop button is pressed

Sponsored Links

understood, ta very much

Presumably (I've not worked on these circuits myself, but they seem interesting), if the switch / coil / cable used has a maximum current rating less than the supply through the contactor, then there should be some sort of fuse / breaker on the feed to the coil from the output of the contactor?

With the start button, would you make it a double throw switch so that when pressed it changes over the connection to the coil from the contactor, as otherwise presumably you are supplying (albeit briefly) whatever is on the output side of the contactor through the button, which as well as potentially exceeding the current rating of the button / associated cabling, would mean that you could push the Go button and have things activate even with an E-stop having been depressed...

Thinking about it, a double throw switch wouldn't actually solve the problem, since when it switched back, there would be a brief interruption, and that could cause the contactor to open?

With the start button, would you make it a double throw switch so that when pressed it changes over the connection to the coil from the contactor, as otherwise presumably you are supplying (albeit briefly) whatever is on the output side of the contactor through the button, which as well as potentially exceeding the current rating of the button / associated cabling, would mean that you could push the Go button and have things activate even with an E-stop having been depressed...

Thinking about it, a double throw switch wouldn't actually solve the problem, since when it switched back, there would be a brief interruption, and that could cause the contactor to open?

It is typical to use a key operated switch with a momentary action to energise the coil, the coil latching on with the auxiliary contacts. A green indicator is also often included.

The red stop button is wired to interupt the supply to the coil, dropping it out. The key operated switch must then be used to re-energise the coil.

The red stop button is wired to interupt the supply to the coil, dropping it out. The key operated switch must then be used to re-energise the coil.

Whenever we fit EPO buttons (which nowadays is not very often) to server racks we install two contactors in parallel/with isolating terminals on the coil/input-output cabling.

Contactors need maintaining so this allows it be down and if need be replaced without downing loads of critical kit. Also for multi rack installations one contactor is a very weak single point of failure.

Contactors need maintaining so this allows it be down and if need be replaced without downing loads of critical kit. Also for multi rack installations one contactor is a very weak single point of failure.

It depents, often if the supply is relatively short then you may not need to provide any additional fault current protection. Dont think a lot of DOL starters have any additional protection for the contactor circuitry.Presumably (I've not worked on these circuits myself, but they seem interesting), if the switch / coil / cable used has a maximum current rating less than the supply through the contactor, then there should be some sort of fuse / breaker on the feed to the coil from the output of the contactor?

No, the start button is a normally open momentary contact. This only ever handles current on the control circuitry. Providing the E-Stops, overload etc are all healthy, pressing the start button will energize the contactor pulling it in, this will then hold in via a N/O control contact across the start button.With the start button, would you make it a double throw switch so that when pressed it changes over the connection to the coil from the contactor, as otherwise presumably you are supplying (albeit briefly) whatever is on the output side of the contactor through the button, which as well as potentially exceeding the current rating of the button / associated cabling, would mean that you could push the Go button and have things activate even with an E-stop having been depressed...

The other N/O contacts are used to supply the load.

Just thought I'd wind my contribution - My server rack has a UPS, so we use a regular wall socket to power the rack when doing stuff so failure no real problem.

I presume the use of a start button to prevent restart is more for machinery and tools rather than servers?

The main thing is am I breaking any laws by having a stop button (which kills both mains and UPS output) that can be restarted by just resetting the button

I presume the use of a start button to prevent restart is more for machinery and tools rather than servers?

The main thing is am I breaking any laws by having a stop button (which kills both mains and UPS output) that can be restarted by just resetting the button

A few years back the local fire authority inspected a large frozen food cold store we do maintenance and installs for. It has an 800amp TP incommer, and 450amp backup gen for the essentials.

The fire authority requested a "Single point of isolation" for the site, to include the mains and the gen. This was obviously not possible as the gen was self starting and was some distance from the actuall mains intake (long story, no room in the inn so to speak).

They then decided they would be happy with a red EM push in the plant room and a firemans switch outside, both to kill the generator and force trip the main ACB.

This could easily be done. The ACB alreay had the shunt fitted, and the gen had an EM stop already adjacent. We could do it easily.

HOWEVER.

Can you imagine the problems if some scrote realised they could isolate the site with the firemans switch? If they did this on a friday night they could kill the power to the site and defrost millions of pounds worth of food!

It was never done, and the local fire authority these days have no say as such. There are signs pointing to the TWO points of isolation now.

The fire authority requested a "Single point of isolation" for the site, to include the mains and the gen. This was obviously not possible as the gen was self starting and was some distance from the actuall mains intake (long story, no room in the inn so to speak).

They then decided they would be happy with a red EM push in the plant room and a firemans switch outside, both to kill the generator and force trip the main ACB.

This could easily be done. The ACB alreay had the shunt fitted, and the gen had an EM stop already adjacent. We could do it easily.

HOWEVER.

Can you imagine the problems if some scrote realised they could isolate the site with the firemans switch? If they did this on a friday night they could kill the power to the site and defrost millions of pounds worth of food!

It was never done, and the local fire authority these days have no say as such. There are signs pointing to the TWO points of isolation now.

- Joined

- 27 Jan 2008

- Messages

- 23,675

- Reaction score

- 2,668

- Location

- Llanfair Caereinion, Nr Welshpool

- Country

Emergency stop buttons come both latching and non latching and can also have key release with the latter then it may be considered that a start button is not required.

But with all these emergency stop systems someone must in writing have completed a risk assessment (All health and safety things must be in writing) LC Automation use to produce the machinery safety handbook and this shows how to categorise into B, 1, 2, 3 or 4 and once this is completed what system can be used to comply. In some cases a single unit is not good enough and twin contact buttons and special safety relays and double contactors are required.

I got caught out when changing a mechanical contactor for an electronic contactor as the latter are not permitted as a safety isolator and I have to double up on main safety contactor. Does seem daft to have one contactor feeding directly into another contactor but it was only way to comply.

So before altering any safety system do read the original assessment and do ensure you are qualified to do the risk assessment, analysis, and/or evaluation and remember there are stop categories 0, 1 and 2 and Emergency Switching off is different to Emergency stop and remember there are set colours Red, Yellow, Green and Blue are all given special functions.

LC Automation do special courses on safety systems and I am sure many other organisations also do courses I would suggest either you are put on the course or someone is employed who has been trained to at least do assessments.

My firm would not send me and they employed a consultant who would visit once a fortnight to ensure we were complying with the regulations.

But with all these emergency stop systems someone must in writing have completed a risk assessment (All health and safety things must be in writing) LC Automation use to produce the machinery safety handbook and this shows how to categorise into B, 1, 2, 3 or 4 and once this is completed what system can be used to comply. In some cases a single unit is not good enough and twin contact buttons and special safety relays and double contactors are required.

I got caught out when changing a mechanical contactor for an electronic contactor as the latter are not permitted as a safety isolator and I have to double up on main safety contactor. Does seem daft to have one contactor feeding directly into another contactor but it was only way to comply.

So before altering any safety system do read the original assessment and do ensure you are qualified to do the risk assessment, analysis, and/or evaluation and remember there are stop categories 0, 1 and 2 and Emergency Switching off is different to Emergency stop and remember there are set colours Red, Yellow, Green and Blue are all given special functions.

LC Automation do special courses on safety systems and I am sure many other organisations also do courses I would suggest either you are put on the course or someone is employed who has been trained to at least do assessments.

My firm would not send me and they employed a consultant who would visit once a fortnight to ensure we were complying with the regulations.

- Joined

- 5 Jan 2005

- Messages

- 119

- Reaction score

- 0

- Country

How big an installation are we talking about here? One cabinet?

Only times I have seen emergency stops is on large server "farms"

Seems a pretty bad idea, the last thing anyone needs is some numpty accidently pressing the button.

Surely flipping the circuit breaker would have the same effect, I could see the point if it was a workshop with heavy machinery but are you likely to get sucked inside of a server via a out of control tape drive

Only times I have seen emergency stops is on large server "farms"

Seems a pretty bad idea, the last thing anyone needs is some numpty accidently pressing the button.

Surely flipping the circuit breaker would have the same effect, I could see the point if it was a workshop with heavy machinery but are you likely to get sucked inside of a server via a out of control tape drive

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Sponsored Links

Similar threads

- Replies

- 16

- Views

- 6K