I would be grateful if anyone could provide ideas/guidance on this issue with my parents boiler.

The central heating engineer who fitted and maintains it, spent a lot of time with it and on the phone, and ended up replacing the pump. £300 later the problem was not fixed!

Problem - Hot water too hot at 65C even when the DHW control is set to its lowest setting of 35C.

Boiler - Vaillant TurboMax Plus 837e, approx 10 years old, serviced annually.

Stuff I’ve investigated using a multimeter, thermometer and Vaillants vrDIALOG/2 diagnostic software -

The central heating engineer who fitted and maintains it, spent a lot of time with it and on the phone, and ended up replacing the pump. £300 later the problem was not fixed!

Problem - Hot water too hot at 65C even when the DHW control is set to its lowest setting of 35C.

Boiler - Vaillant TurboMax Plus 837e, approx 10 years old, serviced annually.

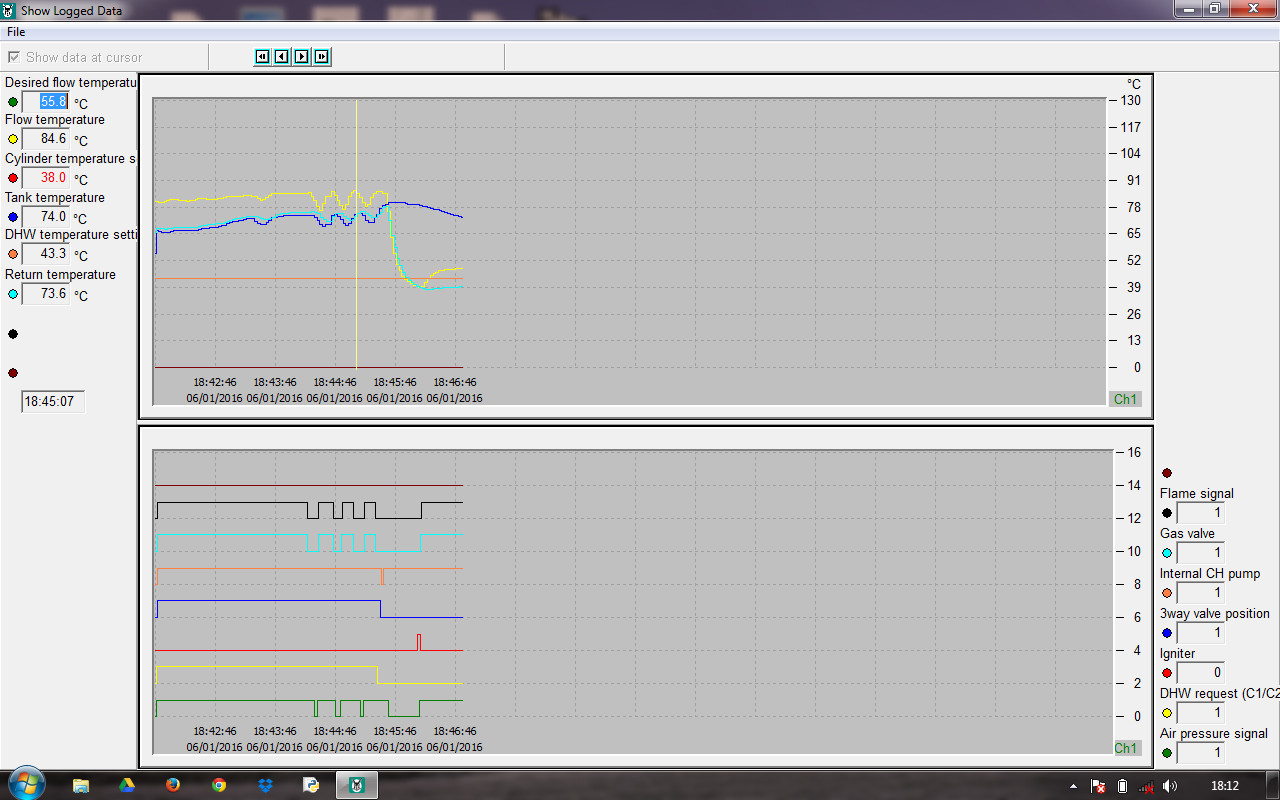

Stuff I’ve investigated using a multimeter, thermometer and Vaillants vrDIALOG/2 diagnostic software -

- All three thermistors (flow, return, warmstart) appear to work normally.

- DHW temperature control operates normally over the range 35-65C as seen both on the boilers LCD display and vrDIALOG software.

- DHW flow as measured by the boiler is OK - reading approx 4% higher than measured flow over the range of 2-15 lpm.

- WarmStart works fine maintaining the DHW heat exchanger at approx 40C.

- The measured gas rate is as per the manufacturer's specification.

- CH flow temperature as set by the CH control is correctly maintained.