Hi,

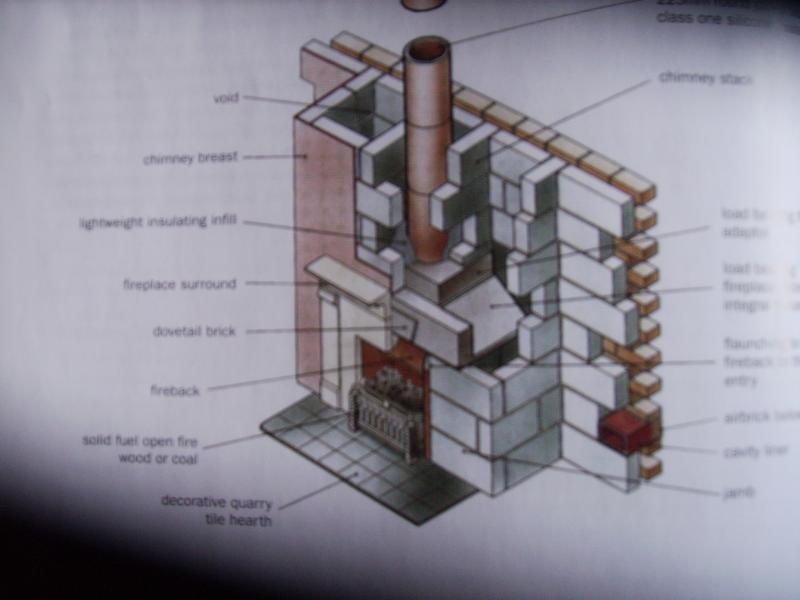

I'm trying to figure out if I can open up my fireplace to fit a stove and have reached a point I don't know if I can pass.

This is my first house and it requires updating. It was built sometime between 1956 and 1962. The fireplace when I bought it was a horrible gas monster, which has been taken out and the gas capped.

Look at that rubbish fire back!

I'm liking the idea of a wood burning stove, and have opened up the fireplace to what I think is the builders opening/recess.

At the top of the image, you can see what I think is a massive precast throated lintel crossed with the top of a fireback sitting on a brick gather.

To fit a stove, I'm probably going to have to remove this thing as I will be wanting to fit a liner suitable for the stove and it won't fit through this opening and I will need the additional height for above the stove to get everything connected. Putting in a lintel in line with the top of this "cast lintel throat thing" gives me three courses worth of height.

My questions are:

1- do you think I can remove this thing without a load of flue falling down?

2- what is this thing called? I'm struggling to research this problem as I don't know what it is!

3- what can I do with the brick gathers beneath it (3 deep but the cast only sits on the front one - not sure what's above the other two brick gathers)? Ideally I don't want them protruding into the opening beneath the lintel. There's also gathers behind the side gathers coming out of the back wall, one course higher which seems to be supporting a sculpted part of the flue.

Thank you for your help - I'm new to this game!

I'm trying to figure out if I can open up my fireplace to fit a stove and have reached a point I don't know if I can pass.

This is my first house and it requires updating. It was built sometime between 1956 and 1962. The fireplace when I bought it was a horrible gas monster, which has been taken out and the gas capped.

Look at that rubbish fire back!

I'm liking the idea of a wood burning stove, and have opened up the fireplace to what I think is the builders opening/recess.

At the top of the image, you can see what I think is a massive precast throated lintel crossed with the top of a fireback sitting on a brick gather.

To fit a stove, I'm probably going to have to remove this thing as I will be wanting to fit a liner suitable for the stove and it won't fit through this opening and I will need the additional height for above the stove to get everything connected. Putting in a lintel in line with the top of this "cast lintel throat thing" gives me three courses worth of height.

My questions are:

1- do you think I can remove this thing without a load of flue falling down?

2- what is this thing called? I'm struggling to research this problem as I don't know what it is!

3- what can I do with the brick gathers beneath it (3 deep but the cast only sits on the front one - not sure what's above the other two brick gathers)? Ideally I don't want them protruding into the opening beneath the lintel. There's also gathers behind the side gathers coming out of the back wall, one course higher which seems to be supporting a sculpted part of the flue.

Thank you for your help - I'm new to this game!