- Joined

- 1 Sep 2015

- Messages

- 371

- Reaction score

- 5

- Country

Hey All,

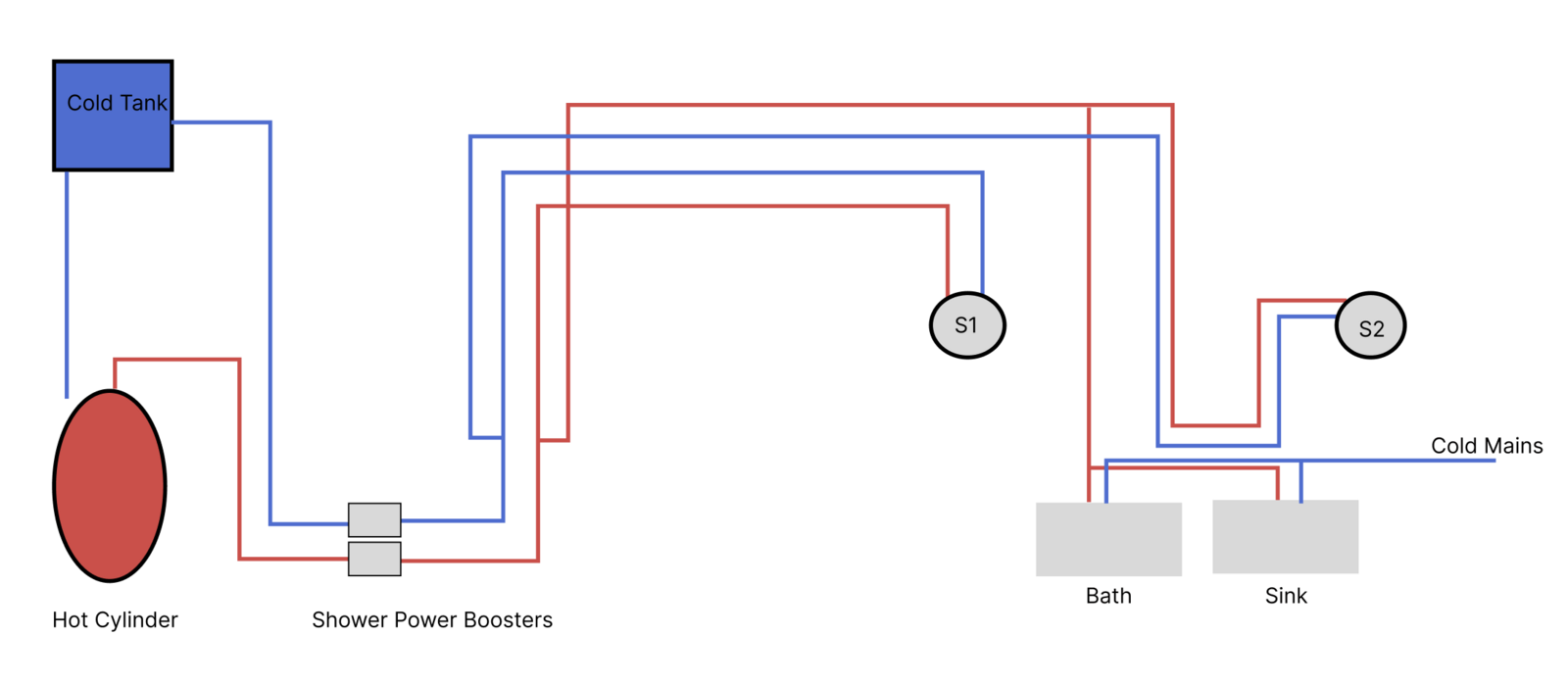

After a bit of advice with our bathroom. The plumbing has been done like below for certain reasons. I've tried to keep the diagram accurate, so where the pipes are going up and down, then it resembles the pipes going vertically to a similarish height to real life.

We initially had a shower pump, however the problem was that the Shower 2 never engaged, I'm assuming because of the multiple ups and downs, and too much negative pressure not triggering the pump. This also caused issues with the bath and sink, as the mains pressure simply overpowered the hot water, so the pump never triggered until only hot water was being called.

We thought that maybe a universal pump would fix the problem due to pressurising the system and using pressure switches, but quickly realised that these double twin impeller pumps run hot and cold at the same time. If the hot was called for the sink or the bath, then it'd burn out the motor because there was no water movement on the cold side. Salamander do have a pump with a crossover that would help this situation, but after calling them, their pumps are not designed for this and warranty will be voided.

Our final attempt has been to use Shower Power Boosters. We have one on the hot and one on the cold. No issues starting the pumps now, but the pressure or flow is absolutely appalling. It takes a few seconds for the pumps to kick in, and when they do, you can see they barely make any difference. We actually get more pressure downstairs from just gravity

Has anyone got any other suggestions? We're at a bit of a loss what to do. It's been suggested to stick 2 power boosters in series, but i'm not really convinced this is going to solve anything.

Would 2 single Universal Shower Pumps works, one for hot, one for cold? I dont want these to cause issues with working against each other and causing some sort of back flow or similar.

After a bit of advice with our bathroom. The plumbing has been done like below for certain reasons. I've tried to keep the diagram accurate, so where the pipes are going up and down, then it resembles the pipes going vertically to a similarish height to real life.

We initially had a shower pump, however the problem was that the Shower 2 never engaged, I'm assuming because of the multiple ups and downs, and too much negative pressure not triggering the pump. This also caused issues with the bath and sink, as the mains pressure simply overpowered the hot water, so the pump never triggered until only hot water was being called.

We thought that maybe a universal pump would fix the problem due to pressurising the system and using pressure switches, but quickly realised that these double twin impeller pumps run hot and cold at the same time. If the hot was called for the sink or the bath, then it'd burn out the motor because there was no water movement on the cold side. Salamander do have a pump with a crossover that would help this situation, but after calling them, their pumps are not designed for this and warranty will be voided.

Our final attempt has been to use Shower Power Boosters. We have one on the hot and one on the cold. No issues starting the pumps now, but the pressure or flow is absolutely appalling. It takes a few seconds for the pumps to kick in, and when they do, you can see they barely make any difference. We actually get more pressure downstairs from just gravity

Has anyone got any other suggestions? We're at a bit of a loss what to do. It's been suggested to stick 2 power boosters in series, but i'm not really convinced this is going to solve anything.

Would 2 single Universal Shower Pumps works, one for hot, one for cold? I dont want these to cause issues with working against each other and causing some sort of back flow or similar.