The pumping over problem is not there on pump speed 1.

On speeds 2 & 3 it starts to happen again.

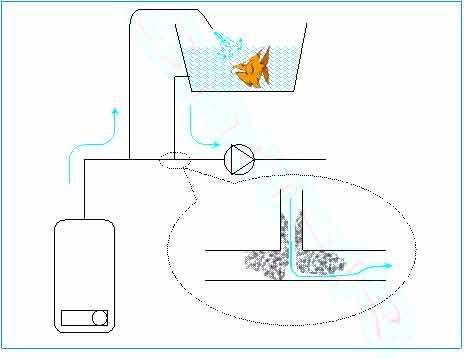

The circuit (up from the boiler) first passes the expansion (overflow?) and then, after 12 inches, it passes the cold feed and then 3 inches further it enters the pump. This pipe is a straight vertical all the way from the boiler (after the first 18 inches of horizontal pipe out of the back of the boiler).

This flow (to the pump) has not been replaced.

If it were slightly blocked would it cause pumping over and how does this happen?

On speeds 2 & 3 it starts to happen again.

The circuit (up from the boiler) first passes the expansion (overflow?) and then, after 12 inches, it passes the cold feed and then 3 inches further it enters the pump. This pipe is a straight vertical all the way from the boiler (after the first 18 inches of horizontal pipe out of the back of the boiler).

This flow (to the pump) has not been replaced.

If it were slightly blocked would it cause pumping over and how does this happen?