Fiat Scudo 2004 2.0JTD (PSA HDI engine)

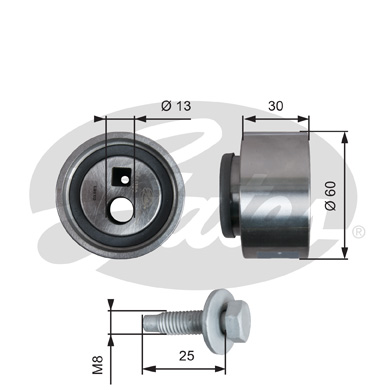

A cam belt change on my van is quite a way off, but I was wondering about the feasibility of changing it myself next time. I've done many different jobs on cars and motorcycles over the years, but never changed a belt. Googling and looking on Youtube, it doesn't seem too difficult, as long as you take your time and are very methodical. I would get a Gates kit and do idler, tensioner and pump all together. The only area that I'm not too clear on is the best tool and method for setting the right tension. My questions;

Is the Sealey belt tensioning gauge in the link the best tool for my situation (DIYer) and vehicle?

Will the gauge even fit where it needs to go between camshaft and fuel pump?

Will I be a able to operate and see the numbers on the gauge when it's in position?

Are there other tools/methods I should consider?

Where would I get the force and deflection specs to use the Sealey tool from?

www.sealey.co.uk

www.sealey.co.uk

I've read some people who did this job and relied on measuring the deflection of the old belt before removal with finger pressure and a rule then using the same measurement on the new belt - or twisting the belt 45 or 90 degrees. I'm guessing that such rule-of-thumb methods aren't recommended?

A cam belt change on my van is quite a way off, but I was wondering about the feasibility of changing it myself next time. I've done many different jobs on cars and motorcycles over the years, but never changed a belt. Googling and looking on Youtube, it doesn't seem too difficult, as long as you take your time and are very methodical. I would get a Gates kit and do idler, tensioner and pump all together. The only area that I'm not too clear on is the best tool and method for setting the right tension. My questions;

Is the Sealey belt tensioning gauge in the link the best tool for my situation (DIYer) and vehicle?

Will the gauge even fit where it needs to go between camshaft and fuel pump?

Will I be a able to operate and see the numbers on the gauge when it's in position?

Are there other tools/methods I should consider?

Where would I get the force and deflection specs to use the Sealey tool from?

Belt Tensioning Gauge | VSE110 | Sealey

1 Year Guarantee - Ensures accurate measurement of belt tension. Clear increment and dual scale for ease of use. Tension chart guide is included.

I've read some people who did this job and relied on measuring the deflection of the old belt before removal with finger pressure and a rule then using the same measurement on the new belt - or twisting the belt 45 or 90 degrees. I'm guessing that such rule-of-thumb methods aren't recommended?