- Joined

- 27 Oct 2020

- Messages

- 113

- Reaction score

- 8

- Country

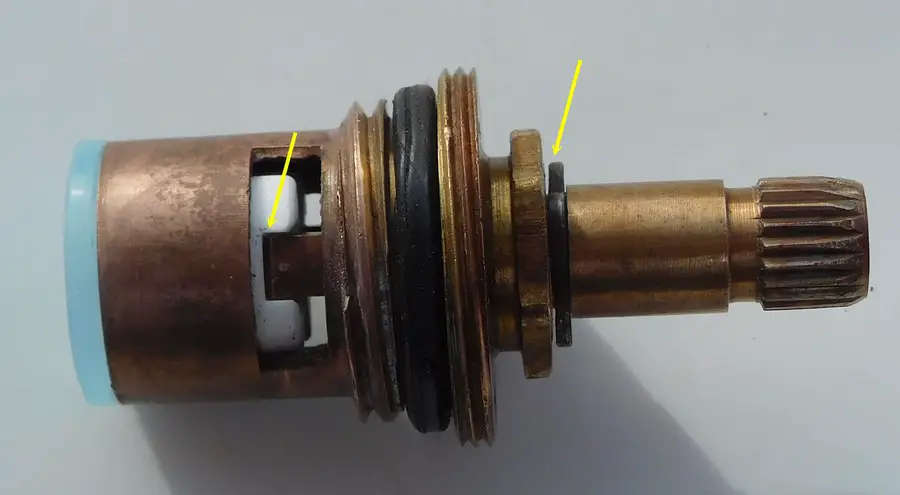

I have a leaking ceramic tap valve (a common problem here I expect). I noticed that the tap shaft felt loose, and the part where the circlip goes wasn't right next to the part where the shaft enters the body of the cartridge, so I dismantled the valve and found that there was a white washer of what looks like nylon, but this was loose and had a space behind it, so as the shaft was put back into the cartridge, it can move too far to the right (as shown in the photos below), thus making the ceramic discs loose, so they leak water.

I fitted an O ring behind the nylon washer, and this worked for a couple of days, then the tap started leaking really badly, and I dismantled it and found that the new O ring had vanished.

Does anybody know what should actually be there behind the nylon washer? Should the nylon washer be much thicker, and has worn down over time? (I've had the taps about three years.) I don't want to dismantle another tap in my house to see what it should look like. (The other tap from where this one came has the same problem, it leaks, and has a small nylon washer.)

Also, are there 18 main types of ceramic tap cartridges? It's a nightmare trying to find a replacement cartridge, with all the different measurements, and it was only after about an hour of searching online that I found two different websites selling cartridges numbered from CC1 to CC18, and they sell a spline finder, a flat piece of metal with holes in it, into which you push the spline of your cartridge, until you find the one that matches - are there really 18 different diameters of splines? The holes on the spline finder don't look like they are big enough to have 18 different diameters, but this is only going by a small photo on a website. This all seems to be something of a black art, a trade secret, where the information about cartridge sizes is kept secret from the public - or maybe my search engine isn't showing me the right website.

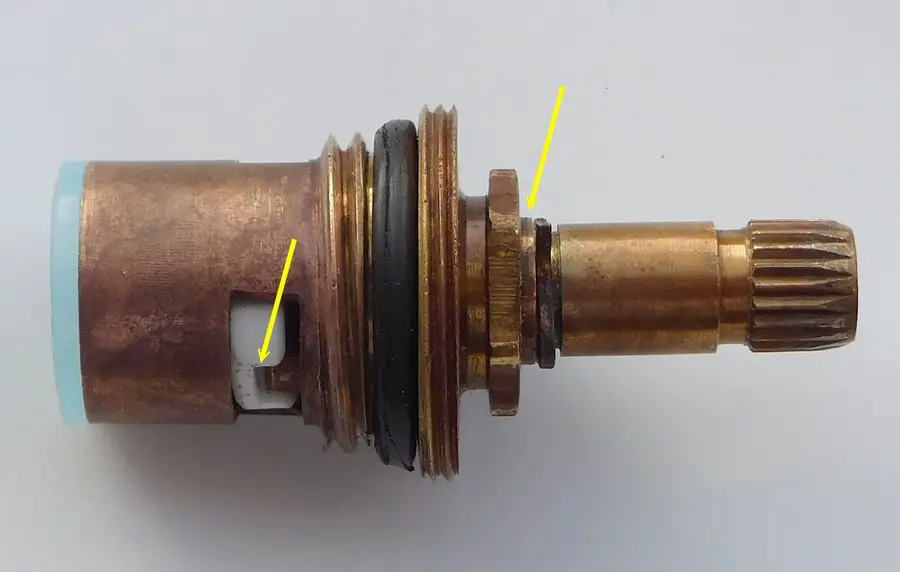

1st photo: Cartridge when I first removed it - notice the left hand arrow shows a big gap between the lower ceramic disc and one of the metal 'prongs' that it rests on. The right hand arrow shows how the shaft has protruded too far to the right.

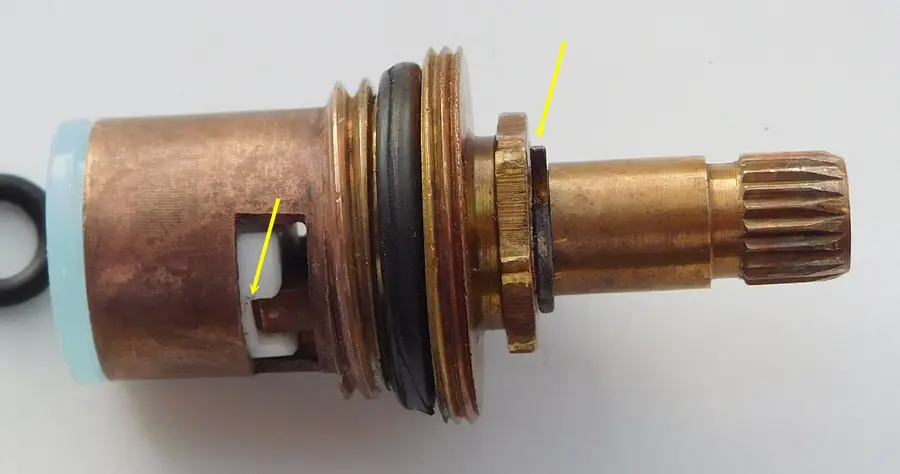

2nd photo: I pushed the shaft to the left to show how it should look when working properly, and creating a good seal between the two ceramic discs.

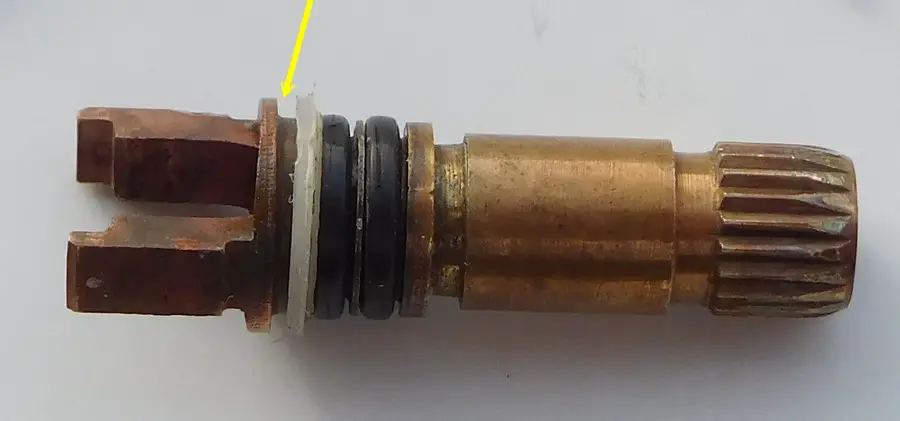

3rd photo: I extracted the shaft and you can see that the nylon washer has a space behind it - when reinserted into the cartridge, the nylon washer will move to the left and there will be a space to the right of it, allowing the shaft to protrude too far to the right, as shown in photo 1.

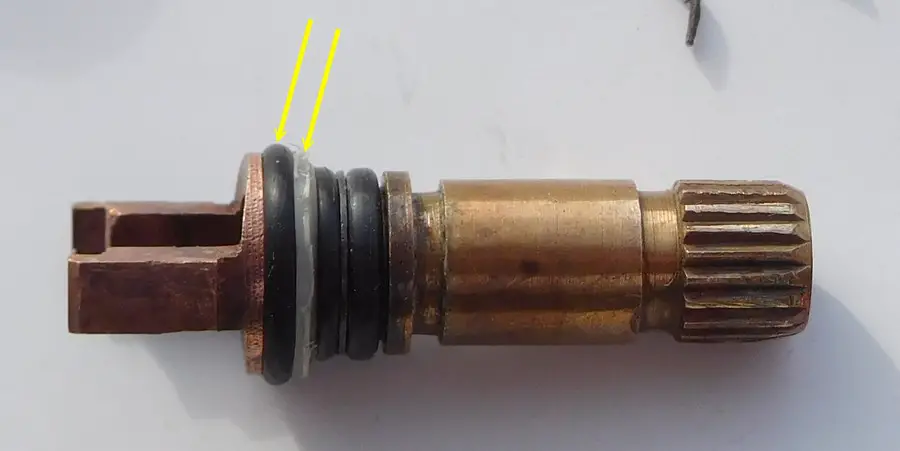

4th photo: I have started to put an O ring onto the shaft.

5th photo: I have put the O ring behind the nylon washer, so it forces the washer to the right (where I believe it should be) so that the shaft can't protrude too far to the right.

6th photo: the shaft is now in the correct position, with the circlip touching the cartridge body, and the shaft cannot move any further to the right, thus the two ceramic discs are pushed together tightly and cannot leak.

I fitted an O ring behind the nylon washer, and this worked for a couple of days, then the tap started leaking really badly, and I dismantled it and found that the new O ring had vanished.

Does anybody know what should actually be there behind the nylon washer? Should the nylon washer be much thicker, and has worn down over time? (I've had the taps about three years.) I don't want to dismantle another tap in my house to see what it should look like. (The other tap from where this one came has the same problem, it leaks, and has a small nylon washer.)

Also, are there 18 main types of ceramic tap cartridges? It's a nightmare trying to find a replacement cartridge, with all the different measurements, and it was only after about an hour of searching online that I found two different websites selling cartridges numbered from CC1 to CC18, and they sell a spline finder, a flat piece of metal with holes in it, into which you push the spline of your cartridge, until you find the one that matches - are there really 18 different diameters of splines? The holes on the spline finder don't look like they are big enough to have 18 different diameters, but this is only going by a small photo on a website. This all seems to be something of a black art, a trade secret, where the information about cartridge sizes is kept secret from the public - or maybe my search engine isn't showing me the right website.

1st photo: Cartridge when I first removed it - notice the left hand arrow shows a big gap between the lower ceramic disc and one of the metal 'prongs' that it rests on. The right hand arrow shows how the shaft has protruded too far to the right.

2nd photo: I pushed the shaft to the left to show how it should look when working properly, and creating a good seal between the two ceramic discs.

3rd photo: I extracted the shaft and you can see that the nylon washer has a space behind it - when reinserted into the cartridge, the nylon washer will move to the left and there will be a space to the right of it, allowing the shaft to protrude too far to the right, as shown in photo 1.

4th photo: I have started to put an O ring onto the shaft.

5th photo: I have put the O ring behind the nylon washer, so it forces the washer to the right (where I believe it should be) so that the shaft can't protrude too far to the right.

6th photo: the shaft is now in the correct position, with the circlip touching the cartridge body, and the shaft cannot move any further to the right, thus the two ceramic discs are pushed together tightly and cannot leak.