Hi,

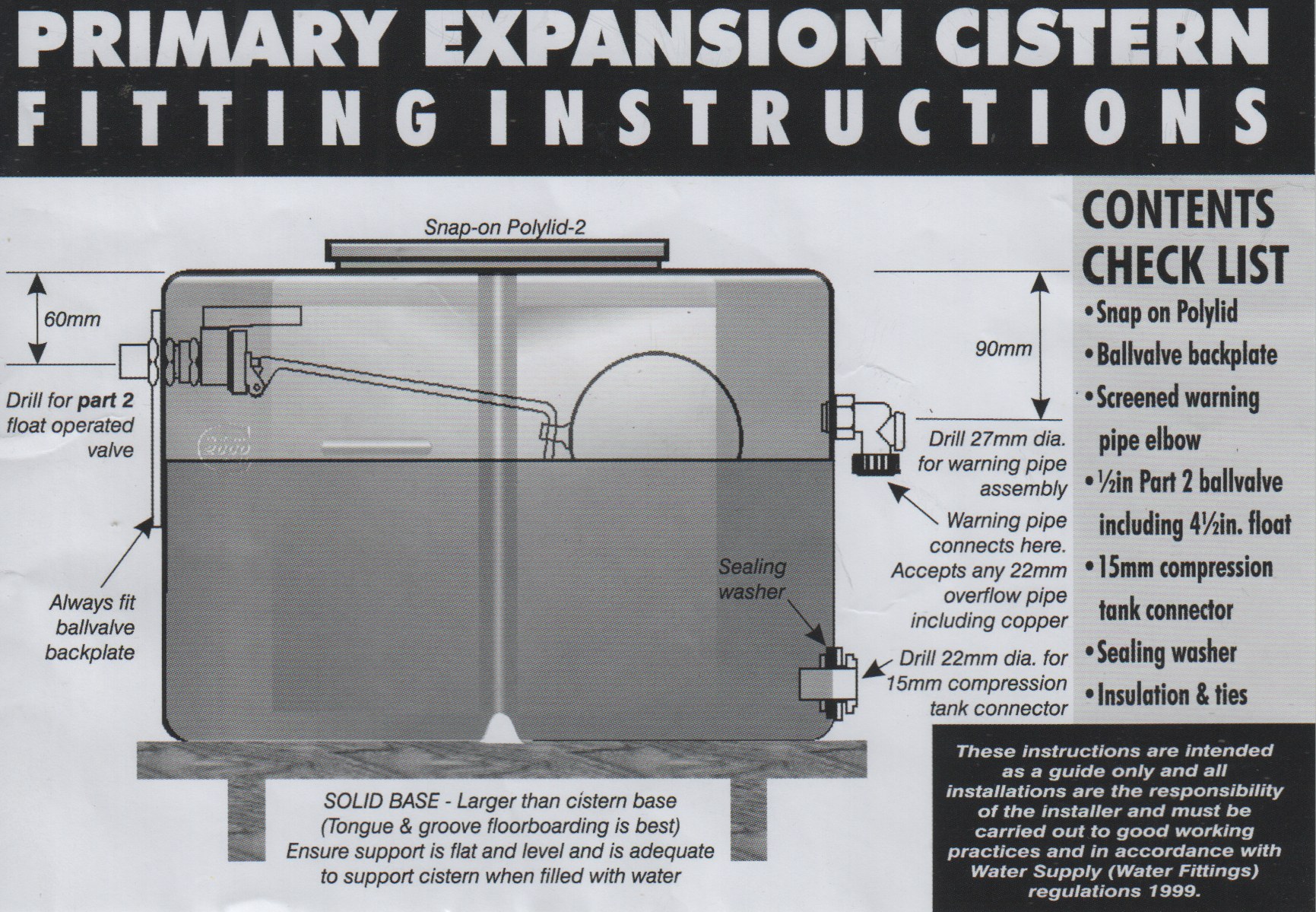

I'm in the process of replacing and relocating my water tanks in the loft. The new cold water storage tank (Polytank Blue) comes with full kit (for a total of 5 holes to be cut into the tank), including what they call a "Screwed Screened Breather" and a "Screwed Vent Pipe Sleeve". The CH cistern (Polytank 18-12-12) comes with a similar kit, but lacks these last two items.

The Vent Pipe Sleeve allows pass-through of the 22mm vent pipe:

The identical looking (but red!) PolyRed comes pre-assembled with the vent pipe sleeve fitted.

So any ideas where can I get a "vent pipe sleeve", preferably online, please?

Failing that, what would you do?

Bonus question, given that the screened overflow already vents to the outside world, and is erm.. screened, what purpose does the separate "Screened Breather" serve?

I'm in the process of replacing and relocating my water tanks in the loft. The new cold water storage tank (Polytank Blue) comes with full kit (for a total of 5 holes to be cut into the tank), including what they call a "Screwed Screened Breather" and a "Screwed Vent Pipe Sleeve". The CH cistern (Polytank 18-12-12) comes with a similar kit, but lacks these last two items.

The Vent Pipe Sleeve allows pass-through of the 22mm vent pipe:

The identical looking (but red!) PolyRed comes pre-assembled with the vent pipe sleeve fitted.

So any ideas where can I get a "vent pipe sleeve", preferably online, please?

Failing that, what would you do?

Bonus question, given that the screened overflow already vents to the outside world, and is erm.. screened, what purpose does the separate "Screened Breather" serve?

Last edited: