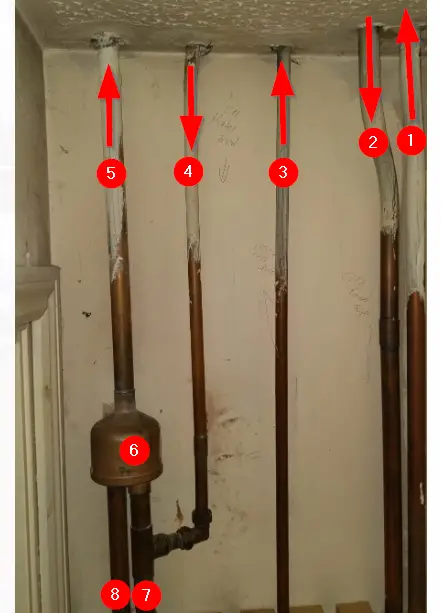

I'm trying to get my head around our CH system and while I think I get most of it, I'm a bit stumped by one or two features. I've labelled the pipes and the bits I'm curious about. Hopefully, someone can explain.

1) Is the expansion for the hot water? Lower down is a T which goes up and down. Up goes through into the loft then turns and drops over the main CW tank.

2) Is the main pipe out of the CW tank? This just drops into the floor. There's another identical pipe on the opposite side which feeds the cylinder.

3) Is the mains supply from downstairs. It goes into the loft, then T's off to feed the main CW tank, and the CH header tank.

4) Is fed from the CH header tank. I presume this keeps the rads topped up somehow.

5) Appears to be another expansion pipe, this time going right to the top of the attic and then turns and drops into the CH header tank.

6) What the hell is this?

7) This comes off the top of the pump.

8) I'd always assumed this merged with 7 in whatever 6 is, and both went up as 5, but having chased 5 to the header tank, I'm guessing 8 is the return to the boiler.

Any explanation is appreciated. I'm not about to start messing with the CH system, but I'd like to know what it's all for. Thanks.

(I wrote on the walls, so that might be wrong).

1) Is the expansion for the hot water? Lower down is a T which goes up and down. Up goes through into the loft then turns and drops over the main CW tank.

2) Is the main pipe out of the CW tank? This just drops into the floor. There's another identical pipe on the opposite side which feeds the cylinder.

3) Is the mains supply from downstairs. It goes into the loft, then T's off to feed the main CW tank, and the CH header tank.

4) Is fed from the CH header tank. I presume this keeps the rads topped up somehow.

5) Appears to be another expansion pipe, this time going right to the top of the attic and then turns and drops into the CH header tank.

6) What the hell is this?

7) This comes off the top of the pump.

8) I'd always assumed this merged with 7 in whatever 6 is, and both went up as 5, but having chased 5 to the header tank, I'm guessing 8 is the return to the boiler.

Any explanation is appreciated. I'm not about to start messing with the CH system, but I'd like to know what it's all for. Thanks.

(I wrote on the walls, so that might be wrong).