- Joined

- 19 Jul 2007

- Messages

- 5,950

- Reaction score

- 1,145

- Country

OK but what is the mechanism that switches the supply to the relay coil ?

The fookin Flow switch !!!!!!

OK but what is the mechanism that switches the supply to the relay coil ?

there is a mechanism. I doubt it would be a Doppler effect flow sensor in a cheap to produce domestic boiler but Doppler sensors do have the advantage of having no moving parts and can be extremely accurate. So turbine, paddle or a diaphram sensing pressure differential across a constriction or something else.fookin Flow switch

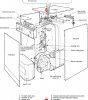

FFS How many more times...........It's a fookin on /off switch that directly puts mains voltage onto the relay actuating coil !!! "Sika" ones were a paddle !Inside the there is a mechanism. I doubt it would be a Doppler effect flow sensor in a cheap to produce domestic boiler but Doppler sensors do have the advantage of having no moving parts and can be extremely accurate. So turbine, paddle or a diaphram sensing pressure differential across a constriction or something else.

Bernardgreen stop digging , as usual you are typing absolute drivel, just give up you are not helping the OP in any way

Your boiler responds solely to a hot water flow.

They normally need a minimum flow rate of 2.5 litres per minute. You can easily measure that. See the FAQ if you need help.

There may be a problem called a crossover at your new tap.

To test that you would need to turn off the water supply going in to your boiler. When you have done that you should get no flow at all from any hot tap.

Tony

We have different opinions, neither of us is clueless, but we do have different motivations behind our opinions. We also have different sources of information and experience. You will never convince me and I woll never convince you. I walk, I do not slopeThe man's a bloody liability - he's sloped off from the UFH thread now he's been proven yet again to be totally clueless.

I choose to live alone,. but I am far from being lonely. DIYnot is an amusing distraction from the more serious things in life,.Bernard possibly lives on his own with DIYnot being his only outlet...

Not a problem if your water supply is not metered but if the customers is on a metered water supply then the cost of wasted water has to be included in the overall cost ( savings ? ) of a combi installation.and whilst they might save energy, they seem seem to waste of lot of water each time you turn the tap on

9.9 Provision should be made to allow air to be vented from the domestic hot water pipework at any high points. Failure to vent the air will cause the flow switch to operate momentarily if a cold water tap is turned off rapidly.

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Are you a trade or supplier? You can create your listing free at DIYnot Local