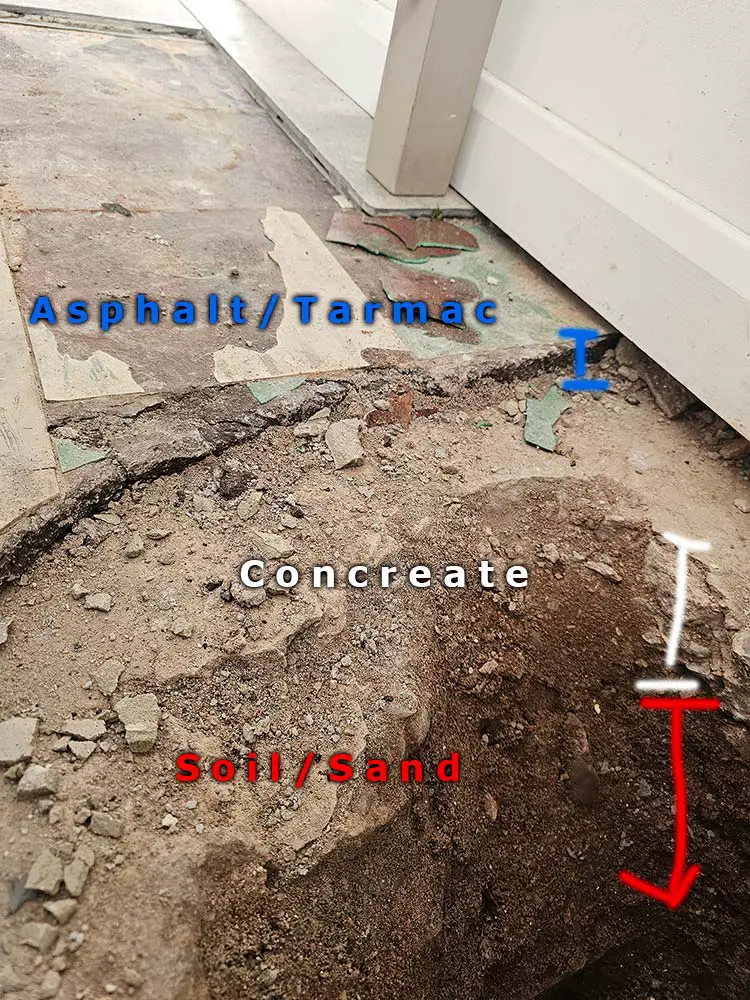

I have a 1950's house. I had a leak in my kitchen, where the mains water pipe comes up into the house before the stop tap. We had to bring up the floor and follow the mains pipe down through the concrete floor and find the clay/ceramic service pipe that houses the copper pipes that goes to the street stop tap and mains water provider. We had to replace about 50cm of copper that had been eaten by the concrete over the last 70 years. Had someone out, thats all fixed.

The issue is the house, like a lot during this time, has a concrete floor supported by an Aspalt/tarmac layer that acts as a dampproof membrane and, by the looks of it, used to level the floor.

My question is how best to repair the Asphalt? Is there a product I can paint down on the concrete, or a screed? My thoughts are that tarmac expands and contracts as I've seen in other areas of the house where we had channels put into the floor for Electric supply to kitchen island etc. The solution they used was to chase the tarmac to leave expansion but unsure of what product they put down? Maybe some sort of flexible waterproof screed?

Any ideas?

The issue is the house, like a lot during this time, has a concrete floor supported by an Aspalt/tarmac layer that acts as a dampproof membrane and, by the looks of it, used to level the floor.

My question is how best to repair the Asphalt? Is there a product I can paint down on the concrete, or a screed? My thoughts are that tarmac expands and contracts as I've seen in other areas of the house where we had channels put into the floor for Electric supply to kitchen island etc. The solution they used was to chase the tarmac to leave expansion but unsure of what product they put down? Maybe some sort of flexible waterproof screed?

Any ideas?