Hi All

Just wondering if anyone familiar with thermal stores could offer some assistance.

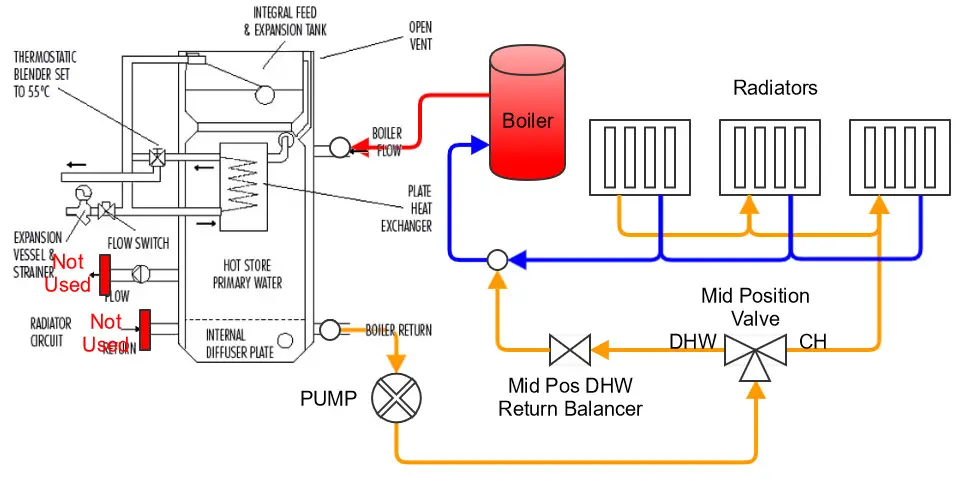

We inherited the system below when we moved into our house in 2010.

The system consists of a Potterton Suprima 60L boiler located in the Garage and Flowmax 140 Thermal Store in the loft.

Recently I have noticed that there is a trickling / pouring noise coming from the loft whenever the pump is running. On investigation the expansion tank was steaming with hot water. Shining a torch in the feed and expansion tank showed that the underwater expansion pipe which comes from the bottom of the hot store was pumping hot water into the expansion tank.

There is no sign that the overall height of the water was increasing significantly, nor has any water reached the overflow which I guess also rules out a leak in the heat exchanger, it seems more like the submerged expansion pipe is "breathing" hot water in and out of the expansion tank.

My thoughts are that perhaps air has accumulated at the top of the hot store? This would explain the pouring noise as the pump pushes hot water from the boiler out of the upper tank inlet above water level, and the higher expansion of the air at the top of the tank could be resulting in the increased "breathing" of the expansion pipe. However should there not be an air vent at the top of the hot store to prevent this? Do these ever get blocked?

Also, our system (with the pump pulling water from the bottom of the store) also seems a little unconventional compared to the layouts I've seen on the internet. Is this an accepted method, or something that could also cause the problems I have?

Thanks in advance:

Paul.

Just wondering if anyone familiar with thermal stores could offer some assistance.

We inherited the system below when we moved into our house in 2010.

The system consists of a Potterton Suprima 60L boiler located in the Garage and Flowmax 140 Thermal Store in the loft.

Recently I have noticed that there is a trickling / pouring noise coming from the loft whenever the pump is running. On investigation the expansion tank was steaming with hot water. Shining a torch in the feed and expansion tank showed that the underwater expansion pipe which comes from the bottom of the hot store was pumping hot water into the expansion tank.

There is no sign that the overall height of the water was increasing significantly, nor has any water reached the overflow which I guess also rules out a leak in the heat exchanger, it seems more like the submerged expansion pipe is "breathing" hot water in and out of the expansion tank.

My thoughts are that perhaps air has accumulated at the top of the hot store? This would explain the pouring noise as the pump pushes hot water from the boiler out of the upper tank inlet above water level, and the higher expansion of the air at the top of the tank could be resulting in the increased "breathing" of the expansion pipe. However should there not be an air vent at the top of the hot store to prevent this? Do these ever get blocked?

Also, our system (with the pump pulling water from the bottom of the store) also seems a little unconventional compared to the layouts I've seen on the internet. Is this an accepted method, or something that could also cause the problems I have?

Thanks in advance:

Paul.

Last edited: