Hello,

I am in the process of building a block-built shed / workshop. It will measure about 7m x 4m, so is below the size at which Building Regs are needed, and I will be keeping the height below 2.5m so Planning Permission is not needed.

Although it's not intended to be habitable space, I want the space to be nice enough that I can usefully use it in the winter, so it is pretty over-specced for a shed. I am planning on building it with a double skin of block work walls, so am digging trench footings 600mm wide, and deep enough to hit our gravel sub-soil (about 1.5m deep). I also have quite a lot of stuff that I want to store in it, so I want to keep it nice and dry.

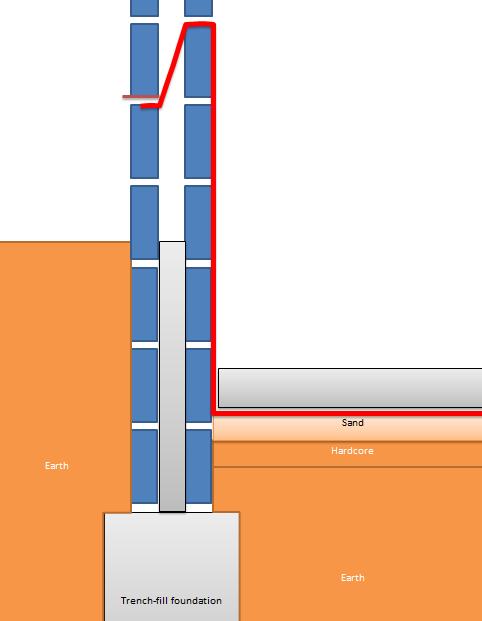

My question is, can I gain a bit of extra storage height by having the internal floor a step or two down from the ground level outside? I am not talking about full cellar territory here, I just thought it would be handy to have it maybe 300mm or 500mm lower inside. The site is quite level.

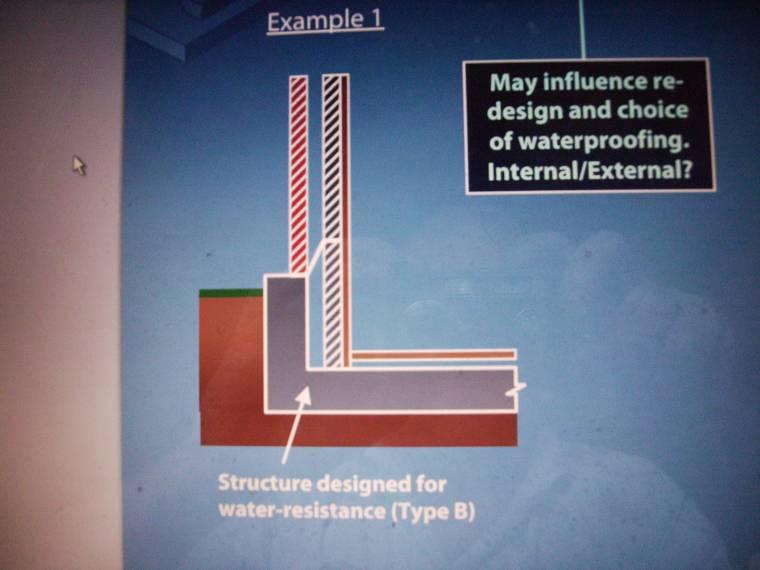

I have had a good trawl of the web, and I haven't been able to find a reason why I shouldn't do this, but then again I haven't found anyone saying that it can be done! All of the helpful diagrams showing you how to arrange your layers (like the one halfway down this link) seem to assume your inside floor level will be about the same as outside ground, if not a bit higher.

I am happy to make a pucker job of this, so for the internal floor I intend to put in a layer of hardcore, blind it with sand, then a DPM, then some insulation, then the concrete floor slab. So, I just wanted to get a view from the knowledgeable folks on here about whether I am likely to come a cropper with any part of this plan.

Thanks in advance,

Jamse

PS - I have put this in the building section, as I figured it's more like building work than putting up a wooden shed, but if the moderators feel that this belongs in the garden section of the forum, please feel free to move it.

I am in the process of building a block-built shed / workshop. It will measure about 7m x 4m, so is below the size at which Building Regs are needed, and I will be keeping the height below 2.5m so Planning Permission is not needed.

Although it's not intended to be habitable space, I want the space to be nice enough that I can usefully use it in the winter, so it is pretty over-specced for a shed. I am planning on building it with a double skin of block work walls, so am digging trench footings 600mm wide, and deep enough to hit our gravel sub-soil (about 1.5m deep). I also have quite a lot of stuff that I want to store in it, so I want to keep it nice and dry.

My question is, can I gain a bit of extra storage height by having the internal floor a step or two down from the ground level outside? I am not talking about full cellar territory here, I just thought it would be handy to have it maybe 300mm or 500mm lower inside. The site is quite level.

I have had a good trawl of the web, and I haven't been able to find a reason why I shouldn't do this, but then again I haven't found anyone saying that it can be done! All of the helpful diagrams showing you how to arrange your layers (like the one halfway down this link) seem to assume your inside floor level will be about the same as outside ground, if not a bit higher.

I am happy to make a pucker job of this, so for the internal floor I intend to put in a layer of hardcore, blind it with sand, then a DPM, then some insulation, then the concrete floor slab. So, I just wanted to get a view from the knowledgeable folks on here about whether I am likely to come a cropper with any part of this plan.

Thanks in advance,

Jamse

PS - I have put this in the building section, as I figured it's more like building work than putting up a wooden shed, but if the moderators feel that this belongs in the garden section of the forum, please feel free to move it.