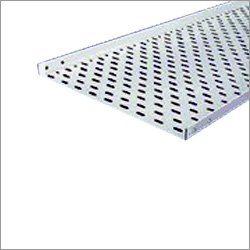

I am building some stairs made with steel stringers and wood plank treads At the top there is a small platform before you step up to the landing. I want to use perforated steel instead of wood for that area.

It is only 700 x 750mm with two steel supports each 150mm wide under them but it needs to be strong enough to take an adult's weight.

I have tried an old 2mm thick scrap piece I found but it bows in the centre with any weight on it so what thickness would anyone recommend ? It will be bolted into the stringers in 6 places, 3 either side with only 330mm unsupported in the centre

It is only 700 x 750mm with two steel supports each 150mm wide under them but it needs to be strong enough to take an adult's weight.

I have tried an old 2mm thick scrap piece I found but it bows in the centre with any weight on it so what thickness would anyone recommend ? It will be bolted into the stringers in 6 places, 3 either side with only 330mm unsupported in the centre