Hello to all at DIYnot Forums, this is my first registered post, this looks an excellent DIY Forum!.

I have the Dreaded Potterton Suprima Lock-out problem, that has been occurring on a random basis for a good while. I have checked the Thermostat & temp sensor & they seem to function ok, also replaced the Pump. The boiler is fitted with the upgraded Siemens control unit 3 years ago.

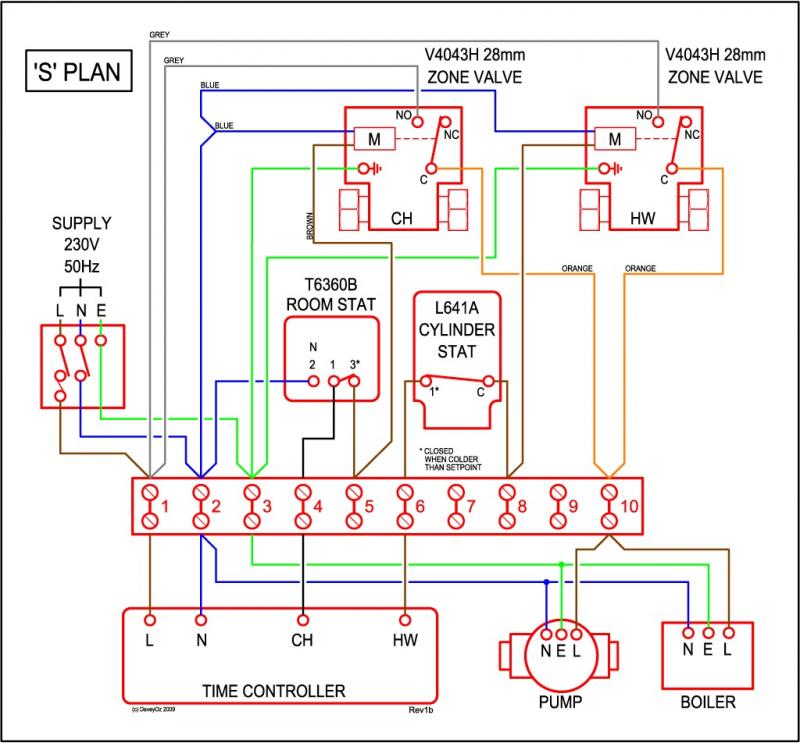

The system is a traditional sealed system - configured & wired as 'S' Plan.

I checked the all the wiring long ago to an S plan schematic and it is correct. The system functions fine when working!.

It has an expansion vessel fitted, the boiler started locking-out again & I noticed the pressure in the tank had gone to near zero -

basically my question is would low-pressure cause random boiler lock-out?.

I have re-charged the vessel to just over 1bar (roughly) so will see what happens now.

The system appears to be leaking all the pressure out, where should I start to look? - apart from the obvious Schrader valve on the vessel.

The lock-outs occur totally at random - morning/night/cold system/hot system etc

Any other relevant tips/points welcome.

I am a 20-year time-served Electrical/Electronics engineer, so you can talk technical to me, I am also a vehicle technician - but I'm specialist Electrical - my knowledge of central heating systems, esp modern is very mediocre!

Thank you in advance

Jamie

I have the Dreaded Potterton Suprima Lock-out problem, that has been occurring on a random basis for a good while. I have checked the Thermostat & temp sensor & they seem to function ok, also replaced the Pump. The boiler is fitted with the upgraded Siemens control unit 3 years ago.

The system is a traditional sealed system - configured & wired as 'S' Plan.

I checked the all the wiring long ago to an S plan schematic and it is correct. The system functions fine when working!.

It has an expansion vessel fitted, the boiler started locking-out again & I noticed the pressure in the tank had gone to near zero -

basically my question is would low-pressure cause random boiler lock-out?.

I have re-charged the vessel to just over 1bar (roughly) so will see what happens now.

The system appears to be leaking all the pressure out, where should I start to look? - apart from the obvious Schrader valve on the vessel.

The lock-outs occur totally at random - morning/night/cold system/hot system etc

Any other relevant tips/points welcome.

I am a 20-year time-served Electrical/Electronics engineer, so you can talk technical to me, I am also a vehicle technician - but I'm specialist Electrical - my knowledge of central heating systems, esp modern is very mediocre!

Thank you in advance

Jamie