Personally I would stay clear of modern pine/softwood whatever way you go forward.

It is nothing like the old slow grown and seasoned pine from years ago. I have seen modern stuff rot through in under a year.

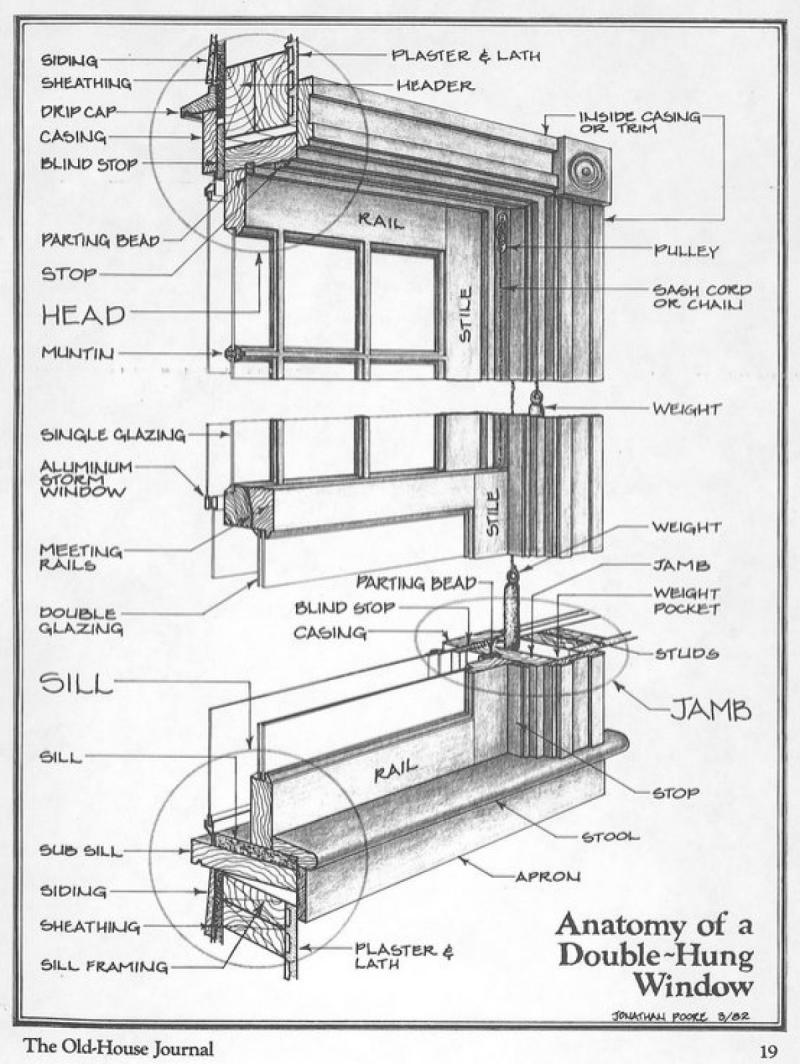

Having refurbed a few sash windows since the 1970s I'd point out that the two worst areas for rot are the cill sections, which mainly tend to rot from the top downwards (the area where paint tends to bubble and crack as the result of neglect), and the water trap at the bottom of the outer beading (a minor design issue in traditional sash windows which face into the weather). Another area for rot is the bottom of the weights box and can often be directly linked to cracked or missing sections of mastic

Most modern window manufacturers install a hardwood sill in Agba or Ipe or the like to overcome the biggest defect and the water-trap problem can be dealt with by cutting the bottom inch or so of the outer bead flush to the sash box face so that water can drain away. The other rot at the bottom of the weight box is really down to neglect - mastic, which is used to seal round the window edges needs to be inspected every two or three years (or more regularly after hot summers which can dry it out and cause cracking) and repaired/replaced probably every 10 to 15 years

Do those three things, and keep-up with the required maintainance of any wooden window (i.e. painting it, see note below) and a sash window will do 100 or more years with ease. Most of the ones requiring major repairs do so because of lack of maintenance more than anything elso IMHO. It's also worth noting that concerns are now being voiced about the longevity of PVCu due to UV-degradation and it's beginning to look like these "maintainence-free miracles" will average 50 to 70 years lifespan - or less than a properly maintained softwood sash window should do

The main difference that first growth softwood timber yoe refer makes is that it is physically somewhat harder (so more wear resistant in the sash frames) and planes slightly better, but that's really about it. Much of it had been clear felled before WWI, let alone WWII, so it's a long time since it's been readily available. But at the end of the day it's still pine, and it will still rot if left exposed to the weather, especially if painted with the wrong paint

On the issue of painting it is worth noting that old windows which have not been painted since gawd only knows when, but which show signs of having been painted with oil-based, lead pigmented paints or chalk paints (so 50 or even 60 years since their last lick of paint) are often in much better condition than those which have been more regularly treated with modern (i.e. post-WWII) alkyd gloss paints. Lead is obviously dangerous and was quite rightly banned a while back, but non-alkyd paints, such as the linseed-oil base

http://www.greenshop.co.uk/natural-paint-128/gloss-exterior-133/holkham-linseed-paints-174/]Holkham - now called

All Back - have shown much improved life over what you can expect with modern gloss paints because they don't trap water and the wood weems better able to "breathe" and lose moisture naturally. I'd hazard a guess that your modern stuff which has rotted through was painted with modern alkyd paints and that was probably the biggest factor in their demise