Earlier in the year I posted the end of a seven year saga to improve the heat in a vertical radiator. It turned out that it had been installed upside down with the diverter sitting in the top rail rather than the bottom beside the input flow. Once turned over it was lovely and warm.

But a couple of weeks later I got a noticeable hum on the pump. So I installed a new UPS2 and got back to an acceptable noise. In hindsight I probably should have flushed the radiator out. Maybe the lack of flow to the top stopped inhibitor getting at all the internals and now I'm suffering the consequences.

At the end of November the noise increased. Turning the speed up to 3 increased the noise but running at speed 1 caused the boiler to 'Kettle'. So I bit the bullet and paid for a Power Flush.

About 2 hours after the plumber left the boiler noise was worse than it's ever been. So I called out Vaillant. They turned up the next day but pronounced the boiler perfect but diagnosed a lack of flow. The first picture below is the state of my new pump. The plumber had connected his kit to the flow and return of the DHW and left the pump in place. His company is not responding to my emails.

So the system is back with the old pump and I thought running acceptably. But Christmas Eve the pump noise returned with a vengeance. I've now set the pump back to speed 1 and reduced the Bypass Valve pressure. The boiler is noise free and running better than ever. The whole system performs its functions well with all radiators coping with the cold and the DHW recovering within 40 minutes. It's just this 'hum' all the time.

The hum is there on DHW, Heating or both. Curiously the noise reduces when both valves close and the flow is just through the bypass. Also I've tried all radiators in turn and the bathroom by itself also reduces the noise. It's the first on the circuit. But the DHW is shorter still and on brand new pipes (only the DHW coil is original).

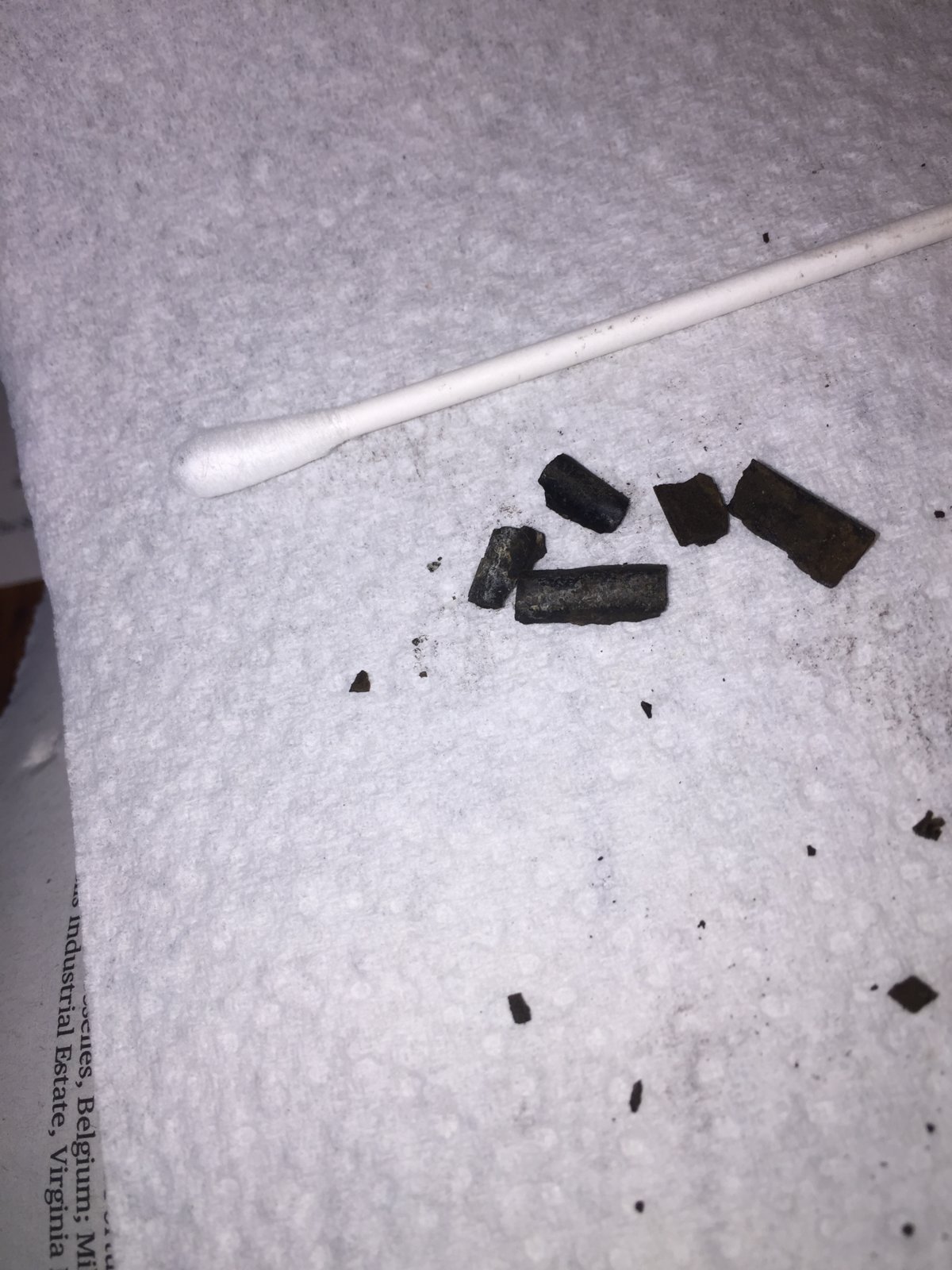

The second picture is the contents from the pump (with cotton bud for sizing)

. Anybody recognise the origin?

. Anybody recognise the origin?

But a couple of weeks later I got a noticeable hum on the pump. So I installed a new UPS2 and got back to an acceptable noise. In hindsight I probably should have flushed the radiator out. Maybe the lack of flow to the top stopped inhibitor getting at all the internals and now I'm suffering the consequences.

At the end of November the noise increased. Turning the speed up to 3 increased the noise but running at speed 1 caused the boiler to 'Kettle'. So I bit the bullet and paid for a Power Flush.

About 2 hours after the plumber left the boiler noise was worse than it's ever been. So I called out Vaillant. They turned up the next day but pronounced the boiler perfect but diagnosed a lack of flow. The first picture below is the state of my new pump. The plumber had connected his kit to the flow and return of the DHW and left the pump in place. His company is not responding to my emails.

So the system is back with the old pump and I thought running acceptably. But Christmas Eve the pump noise returned with a vengeance. I've now set the pump back to speed 1 and reduced the Bypass Valve pressure. The boiler is noise free and running better than ever. The whole system performs its functions well with all radiators coping with the cold and the DHW recovering within 40 minutes. It's just this 'hum' all the time.

The hum is there on DHW, Heating or both. Curiously the noise reduces when both valves close and the flow is just through the bypass. Also I've tried all radiators in turn and the bathroom by itself also reduces the noise. It's the first on the circuit. But the DHW is shorter still and on brand new pipes (only the DHW coil is original).

The second picture is the contents from the pump (with cotton bud for sizing)