Hi all

I wonder if the heating engineers could assist me.

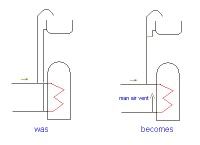

I am fitting a cyl stat and 2 port valve for the DHW. The boiler is in the coal shed as is the pump (in the ret). F&R are teed, one side goes via the grd flr then upstairs and feeds all the rads. There is a 2 port valve in the CH flow. The other side of the tees goes up to the attic, tees again with one side to the cylinder with 2 port valve in the ret. The other side of the attic tees goes to the F&E cistern, F on ret and vent on flow. If the valve on the cyl is closed then the system pumps over via the vent into the F&E. The cylinder is on the attic floor, the F&E is 6 feet higher, the vent goes to the pitch of the roof. Any ideas how to prevent the pumping over please?

Thanks

Martin

I wonder if the heating engineers could assist me.

I am fitting a cyl stat and 2 port valve for the DHW. The boiler is in the coal shed as is the pump (in the ret). F&R are teed, one side goes via the grd flr then upstairs and feeds all the rads. There is a 2 port valve in the CH flow. The other side of the tees goes up to the attic, tees again with one side to the cylinder with 2 port valve in the ret. The other side of the attic tees goes to the F&E cistern, F on ret and vent on flow. If the valve on the cyl is closed then the system pumps over via the vent into the F&E. The cylinder is on the attic floor, the F&E is 6 feet higher, the vent goes to the pitch of the roof. Any ideas how to prevent the pumping over please?

Thanks

Martin