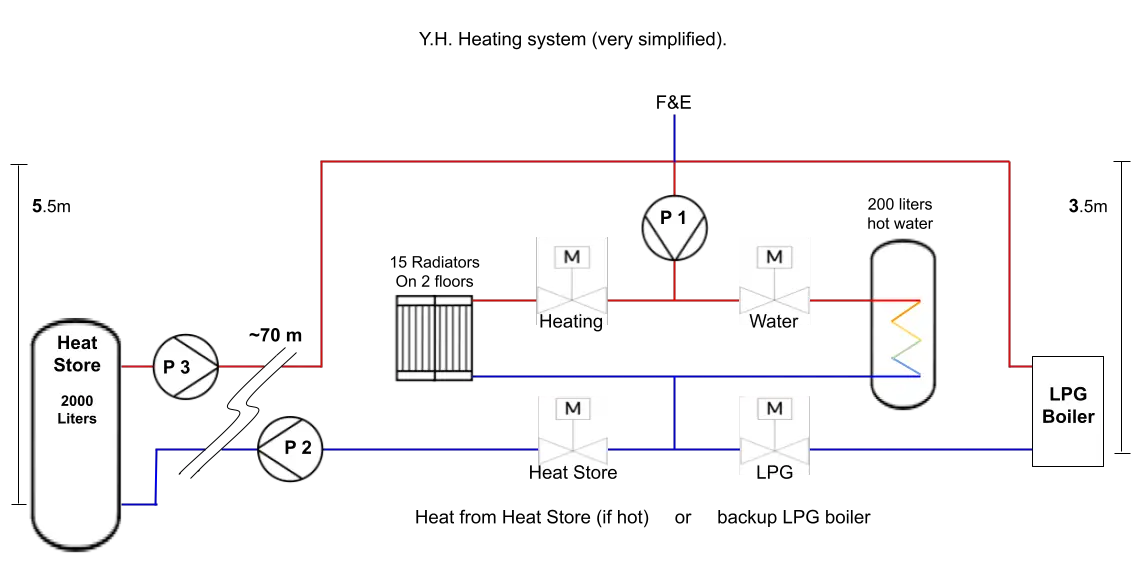

assuming 28mm piping has a ID of 25mm and a total length allowing +10% for bends etc of 154M

This is just the run between the heat store and P1. Not the runs from P1 to the rads.

Do I need to measure the pipe runs in the house?

Do you need to know the lengths broken down by the different pipe diameters?

assuming that the installed rad output is 30kw

Is it useful to measure the rads area²?

An online room calculator said I needed over 50kW!

A rads dT of 15C requires a flowrate of 28.7LM, 1.72M2/hr, 154M of 28mm piping has a dP of ~ 6.9M, add say 1M for dP across the rads = total pumping head of 7.9M.

A rads dT of 20C requires a flowrate of 21.5LM, 1.29M2/hr, 154M of 28mm piping has a dP of ~ 4.1M, add say 1M for dP across the rads = total pumping head of 5.1M.

I think we might need to re-calculate these for the house pipe lengths? Or have I misunderstood?

The UPS3 pump below is a very powerful pump and even on its own should have no problem in circulating 1.29m3/hr (rads dT 20C) as it will supply this flowrate at 6M on CC3.

On setting 1 (in any mode), the boiler overheats and shuts down.

Can you find the pump curves for the other two pumps and post them.

P3:

Grundfos UP single-speed circulator pumps are designed for heating systems, while the three-speed UPS circulator pumps are used in central and district heating system while also being suitable for mixing loops in large systems. Both pumps provide reliable and maintenance-free operation.

product-selection.grundfos.com

P2:

Grundfos UP single-speed circulator pumps are designed for heating systems, while the three-speed UPS circulator pumps are used in central and district heating system while also being suitable for mixing loops in large systems. Both pumps provide reliable and maintenance-free operation.

product-selection.grundfos.com

I would suggest shutting the inlet/outlet isol valves on each pump and remove its head, give the pump ports a quick backflow from each side to prove the pump ports clear and push a tiewrap through the impeller vanes to prove clear.

I have already done that. There was no significant build up of debris etc.

I also checked the capacitor in P3, which was faulty. I have replaced that, but it made no discernable difference.

In desperation (the system failed before Christmas) I bought:

A Wilo Yonos Pico 25/1-8

I tried this in place of P3. It didn't make any functional difference.

I've tried it in place of P2. That hasn't helped either. It's currently still in place of P2.

I feel like there must be some restriction in the pipes somewhere, but I can't figure out how to identify that.

Also that UPS3 has a very disproportionate failure rate and unfortunately does not display the power in watts, a very useful aid on any A rated pump, most makes now do and also didplay the flowrate.

I do like these features on the Yonos Pico.

What is the output of the LPG boiler

42 kW

and its minimum output if it modulates?

I don't know how to find this out .

It does have a fast/slow flame that I can hear. Is this modulation?

and its ~ distance from the rads.

Do I need to measure the pipe runs (see above)?

If so, do you mean distance to the closest or furthest radiator? or an average distance?

Is the boiler heat only with no internal pump?

Yes - no internal pump.