I want to reslate a very old roof.

Presently it has rafter, purlin and Tied Trusses

It has tonnes of old slate (random sizes bed in lime mortar)

It has several layers of grout,,cement slurry on top of lime slurry.

Basically its stood over a hundred years and is well overdue replacement.

unfortunately last winters real cold has allowed the damp to freeze and has splitting open the ridge. (yes there is some splaying of the walls but structural survey said historical).

I propose to reslate it.

Exisiting timbers are sized:

1, trusses 7x2 3/4"

2.purlins 3 x 2 3/4"

3. Rafters 2x2"

Plan

1. leave trusses

2. upgrade purlins to 8x3"

3. upgrade rafters to 4x2"

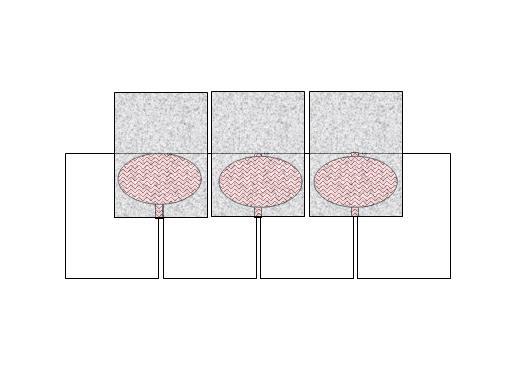

4. consolidate random stone wall tops with concrete ring beam

5. install 4x2" wall plate on top.

I am a little stuck at this point, here are some photos

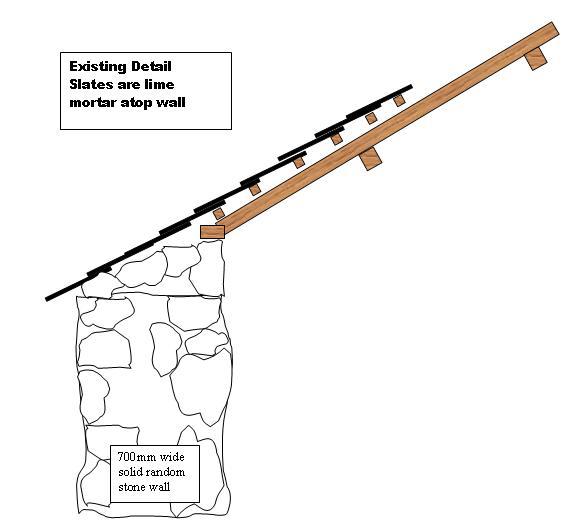

1st one shows eaves detail (or lack of it) i.e slate just protrudes, no rafters showing etc

2nd the roof weighs alot

3rd and 4th shows existing timbers.

You will see no sign of wall plates, rafters just go into wall, however in another part of the building; were I hacked off, you can see wall plate with birdsmouthed rafters sitting square on inside face,,,another words they dont project to outside of the 700mm thick walls. So I assume the slates are just mortar bedded the rest of the way.

After all that my question is:

Options:

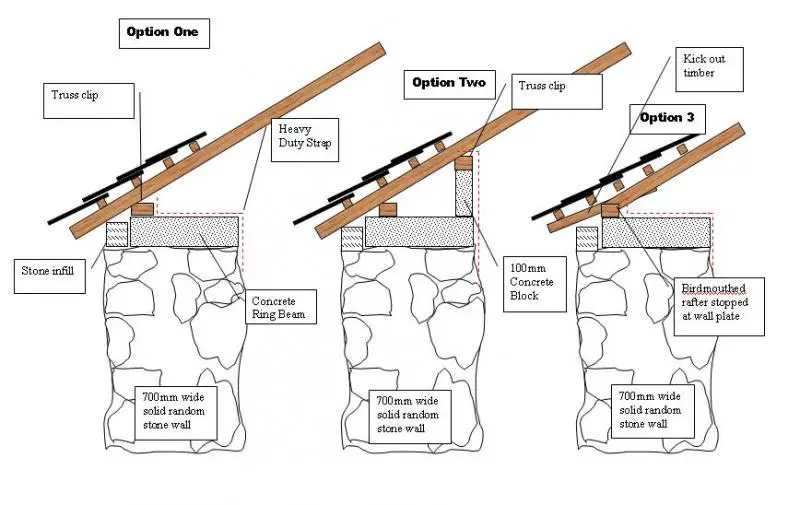

1. If I level walls with a ring beam and I fit a traditional cut roof should I just fix down wall plate to external edge of wall and project rafters using truss clips and create eaves as normal?

2. create ring beam, birdsmouth onto wall plate near external edge and just project slates over similar to existing?

3. create ring beam, build internal leaf one block high, sit wall plate on top and restrain wall plate on inside wall, use truss clips and project through to eaves?

Abit of a conundrum for me really so thought I would put it out here for more heads to look at it.

Many thanks guys.

p.s its only my 3rd post so take it easy, oh and sorry for the long post

Presently it has rafter, purlin and Tied Trusses

It has tonnes of old slate (random sizes bed in lime mortar)

It has several layers of grout,,cement slurry on top of lime slurry.

Basically its stood over a hundred years and is well overdue replacement.

unfortunately last winters real cold has allowed the damp to freeze and has splitting open the ridge. (yes there is some splaying of the walls but structural survey said historical).

I propose to reslate it.

Exisiting timbers are sized:

1, trusses 7x2 3/4"

2.purlins 3 x 2 3/4"

3. Rafters 2x2"

Plan

1. leave trusses

2. upgrade purlins to 8x3"

3. upgrade rafters to 4x2"

4. consolidate random stone wall tops with concrete ring beam

5. install 4x2" wall plate on top.

I am a little stuck at this point, here are some photos

1st one shows eaves detail (or lack of it) i.e slate just protrudes, no rafters showing etc

2nd the roof weighs alot

3rd and 4th shows existing timbers.

You will see no sign of wall plates, rafters just go into wall, however in another part of the building; were I hacked off, you can see wall plate with birdsmouthed rafters sitting square on inside face,,,another words they dont project to outside of the 700mm thick walls. So I assume the slates are just mortar bedded the rest of the way.

After all that my question is:

Options:

1. If I level walls with a ring beam and I fit a traditional cut roof should I just fix down wall plate to external edge of wall and project rafters using truss clips and create eaves as normal?

2. create ring beam, birdsmouth onto wall plate near external edge and just project slates over similar to existing?

3. create ring beam, build internal leaf one block high, sit wall plate on top and restrain wall plate on inside wall, use truss clips and project through to eaves?

Abit of a conundrum for me really so thought I would put it out here for more heads to look at it.

Many thanks guys.

p.s its only my 3rd post so take it easy, oh and sorry for the long post