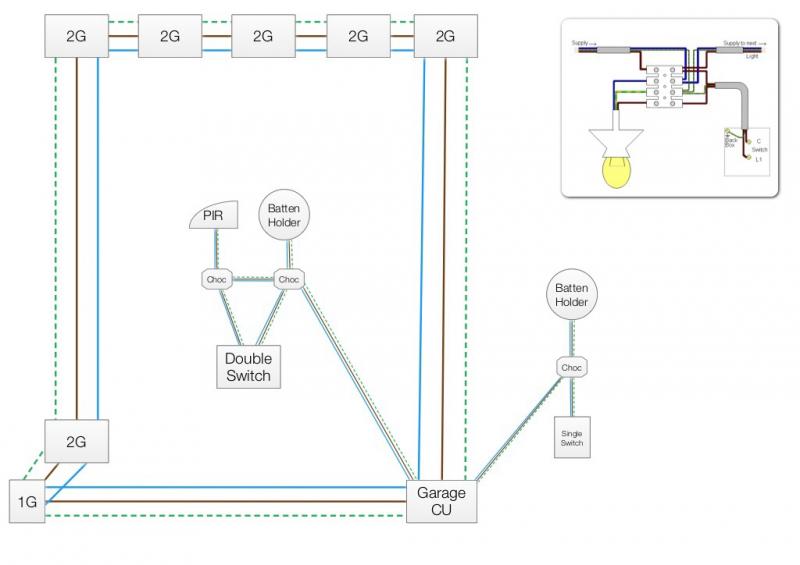

Hi, as it's just a shed I'm going to wire it up myself for the challenge and the cost saving then have someone check it for me when they connect the Garage Consumer Unit to my main one. I've put together a diagram of what I intend to do, here (light connection picture taken from this forum)

I have some questions I'd appreciate help on though please:

- can I run two seperate light circuits as shown but connect them to the same breaker in the Consumer Unit or is this a bad idea?

- does the PIR floodlight need a fuse added inline like it'd have if wired to a socket? If so how do I do this?

- 2.5mm twin core and earth for the sockets; can I use the same for the light circuits too or should I go 1.0mm or 1.5mm?

- the plastic back boxes of the light switches have no metal earth connection point, is this OK and therefore just no need to connect an earth wire to the box?

- any other comments?

Edit:

- also is it ok to run it through and behind Celotex PIR 50mm insulation boards?

- can I seal it into the insulation boards using expanding foam like a grommet when I poke the cable through for access?

I have some questions I'd appreciate help on though please:

- can I run two seperate light circuits as shown but connect them to the same breaker in the Consumer Unit or is this a bad idea?

- does the PIR floodlight need a fuse added inline like it'd have if wired to a socket? If so how do I do this?

- 2.5mm twin core and earth for the sockets; can I use the same for the light circuits too or should I go 1.0mm or 1.5mm?

- the plastic back boxes of the light switches have no metal earth connection point, is this OK and therefore just no need to connect an earth wire to the box?

- any other comments?

Edit:

- also is it ok to run it through and behind Celotex PIR 50mm insulation boards?

- can I seal it into the insulation boards using expanding foam like a grommet when I poke the cable through for access?