Hi all, I've got issues with my shower pump and wondered if anyone could give me some advice on how to resolve the problem?

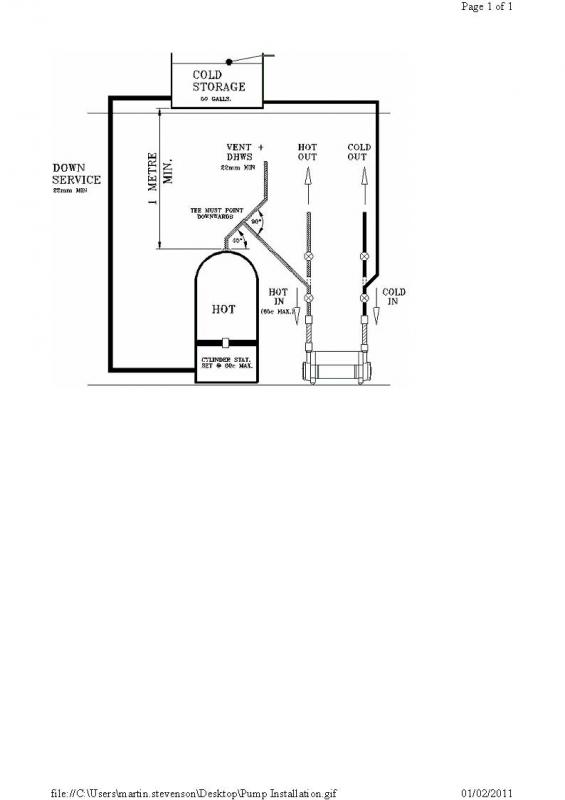

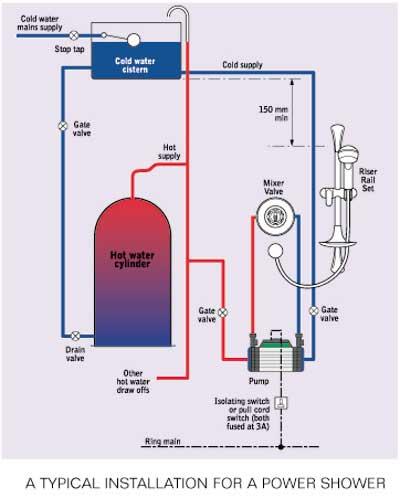

When we bought our new-build house from Persimmon (oh how I wish we'd just built our own!) the water pressure in the shower was terrible so we asked what could be done about it. The site foreman arranged for a pump to be fitted next to the hot water tank and it worked fine for a while but then started playing up.

The hot water tank is in the airing cupboard just next to the en-suite where the shower in question is located. The tank is fed from the cold water supply in the loft.

Early problems were relatively easily fixed - the pump wouldn't work straight away when you turned the shower on so we dropped the shower head down to the tray to allow a better flow of water and the pump would kick in.

When that failed, we'd turn the temperature of the shower all the way down to allow more cold water through the pump - it would then kick in and we'd adjust the temperature after it was running.

As time went on even this wouldn't get the pump going so we had to turn on the shower and then increase the flow of cold water through the pump by opening the valve in the airing cupboard to get it to start. This would drastically lower the temperature of the shower so we then have to decrease the cold input to the pump to get the shower back to a comfortable temperature.

And it's gotten even worse over time - very often the pump will cut out when the shower is in use and to get it back on, you've got to drop the shower head and then increase the cold flow into the pump in the cupboard again to get it to kick in and then reduce it once more so the temperature is comfortable. There is no control of the temperature of the water using the shower controls anymore and it can only be adjusted by altering the cold input to the pump.

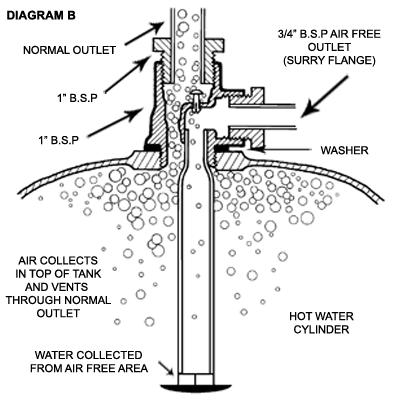

Having taken all of the above into account I assumed it's something to do with the hot water supply going into the pump so I investigated over time and came across people suggesting the use of a Surrey Flange or similar to prevent airlocks in the system (I've already cleaned the filters etc). I thought it may be a bit too much for me to handle so I contacted a local plumber (highly recommended on Checkatrade) to come and have a look for me. When he came out, he told me that a Surrey Flange has a male thread on it and, as my tank also has a male thread, it couldn't be fitted. The only other options open to me would be to fit an electric shower (but according to him the pressure is really low with an electric), attempt to fit an Essex Flange to the side of the tank (but the twice he's tried to do this, it failed), replace the hot tank with one fitted with a female thread on the top (~£800) or better still, replace the whole system with a combi boiler for about £2k.

I have a feeling this isn't 100% true and that there must be some other valve/flange/fitting that can be connected to my tank or the pipes in the system to achieve the same reduction in air coming through the hot feed. I'm well aware that this is a cheap pump & it might have been damaged by the aerated supply or just given up the ghost cos it's a bit crap but if I'm going to have to replace it, I'll still need to have a new one installed correctly so tackling the hot feed is going to be my first job.

I'll upload a couple of images of the set up inside the airing cupboard to show what's there already and I'd appreciate it if someone could point me in the right direction of how to rectify the situation.

Thanks a lot for any advice.

Mike

When we bought our new-build house from Persimmon (oh how I wish we'd just built our own!) the water pressure in the shower was terrible so we asked what could be done about it. The site foreman arranged for a pump to be fitted next to the hot water tank and it worked fine for a while but then started playing up.

The hot water tank is in the airing cupboard just next to the en-suite where the shower in question is located. The tank is fed from the cold water supply in the loft.

Early problems were relatively easily fixed - the pump wouldn't work straight away when you turned the shower on so we dropped the shower head down to the tray to allow a better flow of water and the pump would kick in.

When that failed, we'd turn the temperature of the shower all the way down to allow more cold water through the pump - it would then kick in and we'd adjust the temperature after it was running.

As time went on even this wouldn't get the pump going so we had to turn on the shower and then increase the flow of cold water through the pump by opening the valve in the airing cupboard to get it to start. This would drastically lower the temperature of the shower so we then have to decrease the cold input to the pump to get the shower back to a comfortable temperature.

And it's gotten even worse over time - very often the pump will cut out when the shower is in use and to get it back on, you've got to drop the shower head and then increase the cold flow into the pump in the cupboard again to get it to kick in and then reduce it once more so the temperature is comfortable. There is no control of the temperature of the water using the shower controls anymore and it can only be adjusted by altering the cold input to the pump.

Having taken all of the above into account I assumed it's something to do with the hot water supply going into the pump so I investigated over time and came across people suggesting the use of a Surrey Flange or similar to prevent airlocks in the system (I've already cleaned the filters etc). I thought it may be a bit too much for me to handle so I contacted a local plumber (highly recommended on Checkatrade) to come and have a look for me. When he came out, he told me that a Surrey Flange has a male thread on it and, as my tank also has a male thread, it couldn't be fitted. The only other options open to me would be to fit an electric shower (but according to him the pressure is really low with an electric), attempt to fit an Essex Flange to the side of the tank (but the twice he's tried to do this, it failed), replace the hot tank with one fitted with a female thread on the top (~£800) or better still, replace the whole system with a combi boiler for about £2k.

I have a feeling this isn't 100% true and that there must be some other valve/flange/fitting that can be connected to my tank or the pipes in the system to achieve the same reduction in air coming through the hot feed. I'm well aware that this is a cheap pump & it might have been damaged by the aerated supply or just given up the ghost cos it's a bit crap but if I'm going to have to replace it, I'll still need to have a new one installed correctly so tackling the hot feed is going to be my first job.

I'll upload a couple of images of the set up inside the airing cupboard to show what's there already and I'd appreciate it if someone could point me in the right direction of how to rectify the situation.

Thanks a lot for any advice.

Mike