Had a less than stellar day yesterday, bleeding an old rad in which I'd recently fitted new TRV and lockshield and managed to shear then bleed screw end off.

I've since discovered a variety of online retailers who sell a variety radiator bleed screws (I've ordered a multipack with an option to return unused ones).

However my conundrum is as follows:

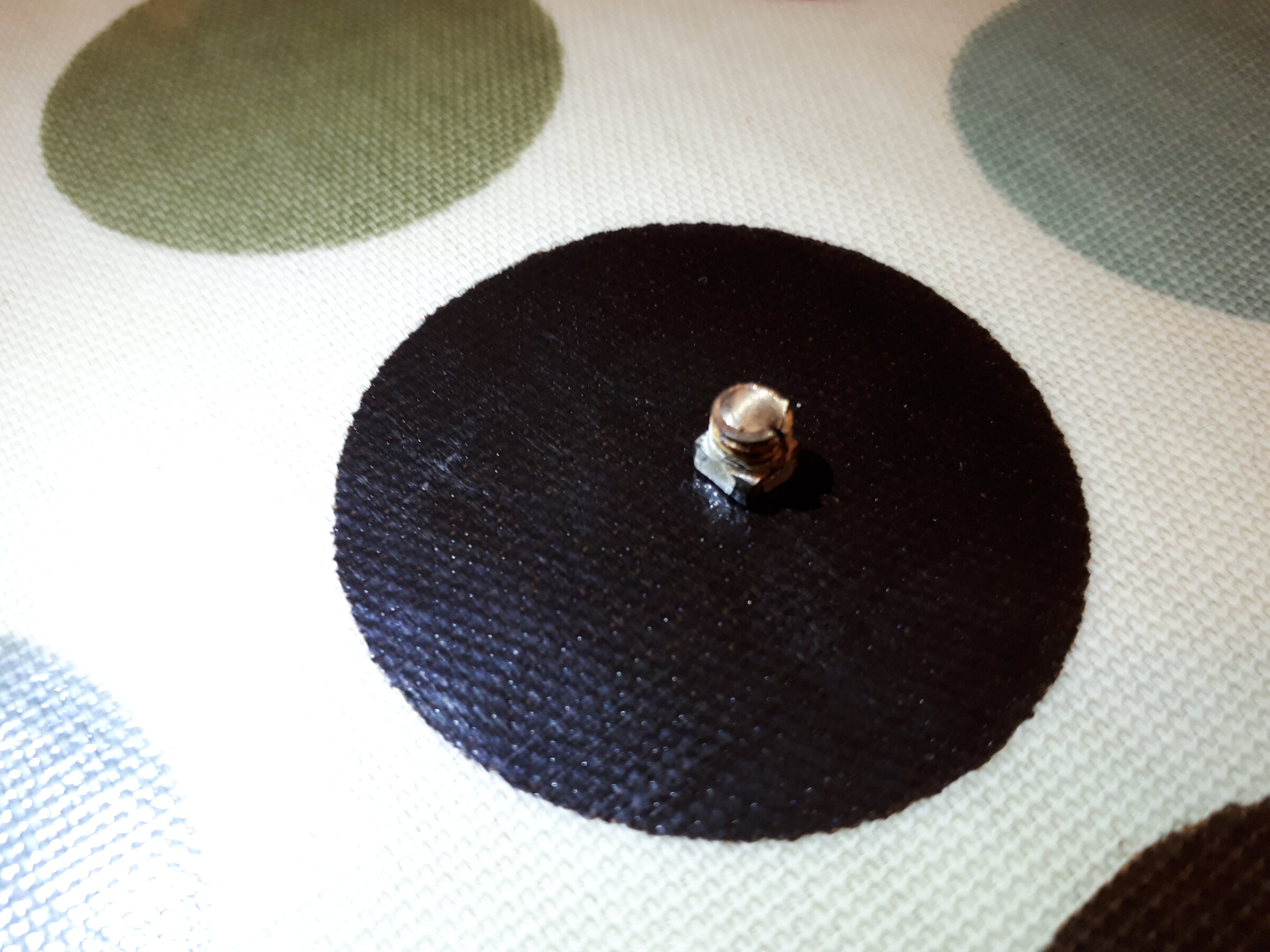

I need to get the remains of the old screw out, or put a new one in the other end. The design is less than optimal, in that there's no removable boss, and the screw is shrouded by the radiator top. Its approx 5mm in dia, which I can probably drill out but I could do with knowing the thread form so I can run a tap through it to clear it - or chicken option - drill and tap a fresh hole in the other end.

So any suggestions as to the thread size and tap to use? I'm guessing its a taper (most plumbing stuff seems to be) as it would then be self sealing.

The website selling the screws suggests a range of sizes around 4.6 to 4.8mm for this application, and 30TPI - casual searching doesn't bring up any taps of that size. Is there something else I should be looking for?

I've since discovered a variety of online retailers who sell a variety radiator bleed screws (I've ordered a multipack with an option to return unused ones).

However my conundrum is as follows:

I need to get the remains of the old screw out, or put a new one in the other end. The design is less than optimal, in that there's no removable boss, and the screw is shrouded by the radiator top. Its approx 5mm in dia, which I can probably drill out but I could do with knowing the thread form so I can run a tap through it to clear it - or chicken option - drill and tap a fresh hole in the other end.

So any suggestions as to the thread size and tap to use? I'm guessing its a taper (most plumbing stuff seems to be) as it would then be self sealing.

The website selling the screws suggests a range of sizes around 4.6 to 4.8mm for this application, and 30TPI - casual searching doesn't bring up any taps of that size. Is there something else I should be looking for?