You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

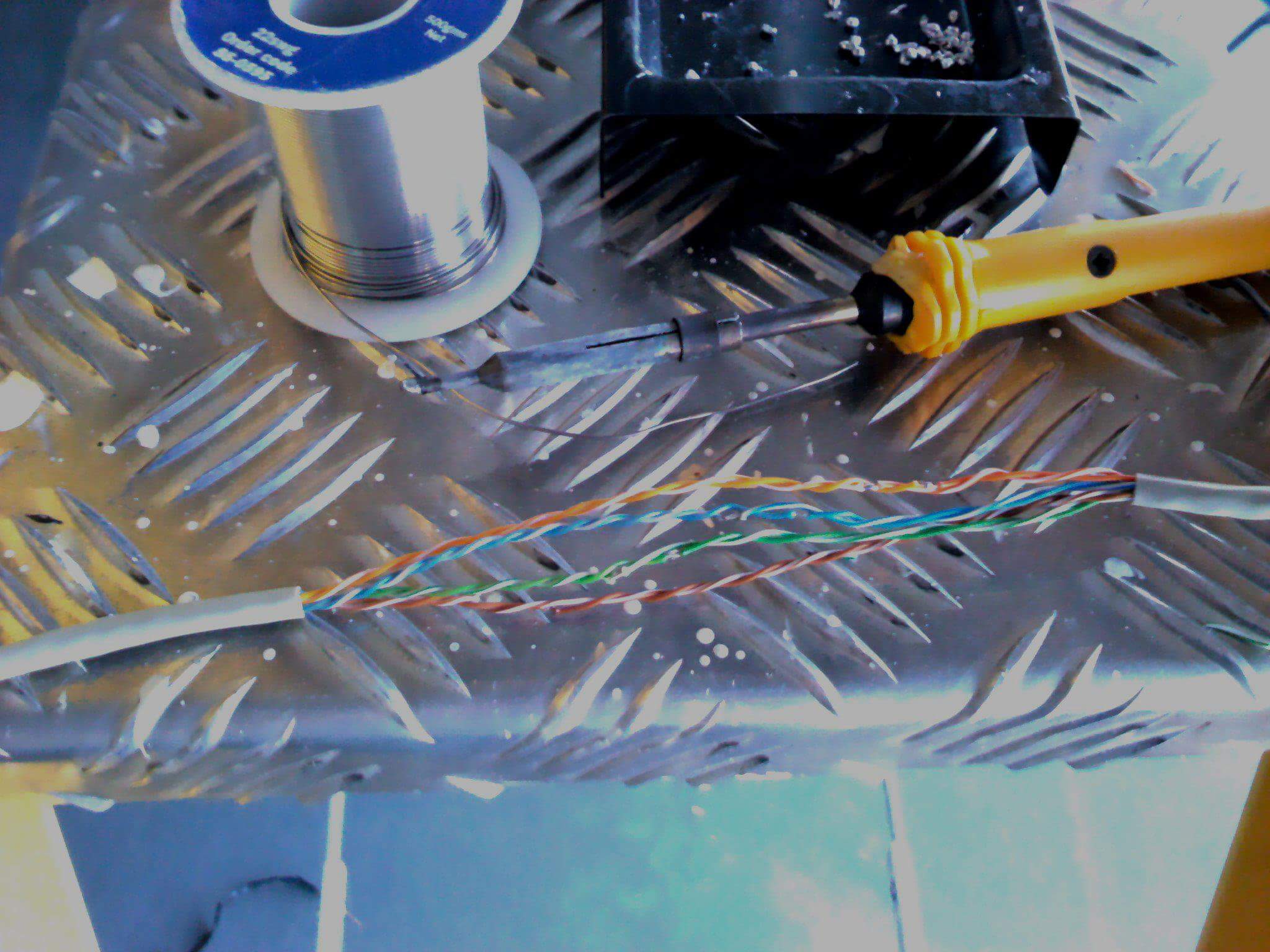

Sparky tried to do CAT5 repair!

- Thread starter m0bov

- Start date

Not sure the problem is so much the jellies, but rather the large amount of each pair thats been untwisted to go the joint and then all the unpaired conductors from all the pairs are then all tangled around one another. I reckon if you only had jellies and you needed to get a joint done, you could do something that worked almost as well as the proper connector

I've done several repairs that way. Always kept the twist on the pairs as best as possible and always got away with it. Its not the best method but if your not pushing it on cable run length it should still be running faster than 10.

Another way to splice them together is by soldering with stagered joints (that way you can get away without individualy insulating each joint), keeping the twist as it should be and just put heatshrink over the whole joint. Ive had success with that method on cable runs of near 100m with no speed issues.

It may be a bad connector/faceplate at the ends of the run, its suprising how often that can occur - even though they may look to be ok. Sometimes you'll get ones that will work with one thing pluged in but something else just doesnt get a good connection - can just be bad moulding of plastic plug/socket or just poor crimp/punch.

Last edited:

- Joined

- 27 Jan 2008

- Messages

- 28,085

- Reaction score

- 3,408

- Location

- Llanfair Caereinion, Nr Welshpool

- Country

I have found in the past that it is often due to not selecting the pairs correctly, as already said to work the cores have to be twisted standard transmission line theory,

The orange however does not connect to adjacent pins but to 3 and 6, which also pushed the blue to the centre, one can see why a single pair connect to centre pins, but the number of times I have found the tester shows connected correct but in fact the blue and orange are using wrong pins.

The orange however does not connect to adjacent pins but to 3 and 6, which also pushed the blue to the centre, one can see why a single pair connect to centre pins, but the number of times I have found the tester shows connected correct but in fact the blue and orange are using wrong pins.

The wall socket is really confusing since it seems the moving of pins 3 to 6 is done inside the socket

note 3 and 6 are sitting next to each other, so easy to read 1, 2, 3, and expect the next pin to be 4, I know I have made errors in the early days, this is more likely to be problem than the connector block used.

note 3 and 6 are sitting next to each other, so easy to read 1, 2, 3, and expect the next pin to be 4, I know I have made errors in the early days, this is more likely to be problem than the connector block used.

The wall socket is really confusing since it seems the moving of pins 3 to 6 is done inside the socket

- Joined

- 27 Jan 2008

- Messages

- 28,085

- Reaction score

- 3,408

- Location

- Llanfair Caereinion, Nr Welshpool

- Country

That's odd the plug wiring showed in the reply before and in the edit, but not on the post, see if this

version works, here it is the green and blue one is likely to get wrong.

version works, here it is the green and blue one is likely to get wrong.

Got asked to look at a slow internet connection, found a join in an out building.

https://photos.app.goo.gl/gLDb9GQScxrIsy1s1

I guess this is reason why the PC would only run at 10Mbps!

Got an IDC CAT6 box to punch down and re join the cables.

On closer inspection zooming in on the photo it looks like the cables have been stripped before being put in the crimps (certainly the blue wire )??

They are designed to be self cutting through the insulation so no stripping required. I wonder if the lack of insulation has narrowed the cable enough for the act of crimping to not have actually pushed the wire into the connector properly causing bad connections?

- Joined

- 25 Apr 2016

- Messages

- 2,863

- Reaction score

- 711

- Country

Firstly the 'jelly' crimps are the correct joins for use in damp (i.e outside) environments. The 'jelly' - either silicon grease or petroleum jelly - is intended to stop corrosion. Certainly the disturbance to the pairs won't help the speed. I'd say that the change to an internal IDC box won't in the long run help the network performance.

How long is the cable run? In practise the longer runs will slow the network speed down. A long run with a joint in the middle will have an effect on speed.

Researching my reply there is a couple of actions, discussions that could help - see :-

http://www.tomshardware.co.uk/forum/22511-42-cable-long-quot-long-quot

http://www.ciscopress.com/articles/article.asp?p=31276

Their is also 'discussions' on 'Toms Hardware' web pages.

The IDC & Crimp Jelly connectors (which are a form of IDC) work on the principle of 'Cold Welds' pushing the (solid) wire into the IDC slot cuts through the Insulation and the 'tinning' on the conductor allowing the copper in the wire and the IDC to make the cold weld. Of course if the wire is copper clad Aluminum or evan copper clad steel - it isn't any where as effective...

How long is the cable run? In practise the longer runs will slow the network speed down. A long run with a joint in the middle will have an effect on speed.

Researching my reply there is a couple of actions, discussions that could help - see :-

http://www.tomshardware.co.uk/forum/22511-42-cable-long-quot-long-quot

http://www.ciscopress.com/articles/article.asp?p=31276

Their is also 'discussions' on 'Toms Hardware' web pages.

The IDC & Crimp Jelly connectors (which are a form of IDC) work on the principle of 'Cold Welds' pushing the (solid) wire into the IDC slot cuts through the Insulation and the 'tinning' on the conductor allowing the copper in the wire and the IDC to make the cold weld. Of course if the wire is copper clad Aluminum or evan copper clad steel - it isn't any where as effective...

- Joined

- 27 Jan 2008

- Messages

- 28,085

- Reaction score

- 3,408

- Location

- Llanfair Caereinion, Nr Welshpool

- Country

I would likely use two RJ45 plugs and a through coupler and put the whole lot in petroleum jelly inside the JB, as to if that is correct I don't know? But it does allow easy testing both on install and in the future, however I would still say I have personally found low speed normally due to wrong wires paired together.

Since the same plug and socket can be used with one pair or four pairs, the centre two connectors are taken as first pair, the two connectors either side are taken as second pair, then the pairs are next to each other, so a plug with only two wires can be used with one using all eight. Never seen LAN with just two, but same principle is used with telephone.

With short leads getting the pairs mixed up does not matter so much, and I will admit in the early days I got it wrong, I could not understand why my patch leads were OK but my long leads failed. And even after I worked out my error, correcting all my patch leads took some time, I likely still have one or two around, add to this my tester takes RJ45 plugs, so to test a wall socket I need to use a patch lead, so pick up faulty patch lead and one can correct the fault in the socket so tester shows all OK but this is not really the case.

I now always test patch lead first I have learnt how to avoid those errors now, however I would assume others are still getting it wrong, and with the cheap cable tester it does not even flag it up on the tester. So I would say that is far more likely to be the reason for low speed than using gel connectors.

Since the same plug and socket can be used with one pair or four pairs, the centre two connectors are taken as first pair, the two connectors either side are taken as second pair, then the pairs are next to each other, so a plug with only two wires can be used with one using all eight. Never seen LAN with just two, but same principle is used with telephone.

With short leads getting the pairs mixed up does not matter so much, and I will admit in the early days I got it wrong, I could not understand why my patch leads were OK but my long leads failed. And even after I worked out my error, correcting all my patch leads took some time, I likely still have one or two around, add to this my tester takes RJ45 plugs, so to test a wall socket I need to use a patch lead, so pick up faulty patch lead and one can correct the fault in the socket so tester shows all OK but this is not really the case.

I now always test patch lead first I have learnt how to avoid those errors now, however I would assume others are still getting it wrong, and with the cheap cable tester it does not even flag it up on the tester. So I would say that is far more likely to be the reason for low speed than using gel connectors.

If using a coupler to connect two plugs - make sure you get one that's explicitly rated as "Cat5e" (or even Cat6). Most of the couplers are not designed for that and do not make any attempt to maintain the twisted pair characteristics. I've tested it, and with a half decent tester* the reflections and crosstalk introduced by a cheap coupler are clear to see. It won't matter on a short link, but on a longer link it could make the difference between "good" and "unreliable".

There also exist Cat5e junction boxes that are just like those small white JBs used on phone lines - but with a board inside designed for connecting network cables. While not as easy for testing as having a plug you can unplug to test each way, IMO using a small JB is going to be quicker and more reliable than field fitting 2off RJ45 plugs** - at least if you possess a Krone punchdown tool rather than just ramming the wires in with a screwdriver

* Mine is only an old ex-rental Fluke DSP-100, but it's still very useful for testing and fault finding even if it's only Cat5 (not even Cat5e).

** I've seen a lot of field fitted RJ45 plugs, many (I'd say the vast majority) "leave a lot to be desired"

There also exist Cat5e junction boxes that are just like those small white JBs used on phone lines - but with a board inside designed for connecting network cables. While not as easy for testing as having a plug you can unplug to test each way, IMO using a small JB is going to be quicker and more reliable than field fitting 2off RJ45 plugs** - at least if you possess a Krone punchdown tool rather than just ramming the wires in with a screwdriver

* Mine is only an old ex-rental Fluke DSP-100, but it's still very useful for testing and fault finding even if it's only Cat5 (not even Cat5e).

** I've seen a lot of field fitted RJ45 plugs, many (I'd say the vast majority) "leave a lot to be desired"

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 2

- Views

- 1K

- Replies

- 0

- Views

- 582