- Joined

- 19 Dec 2023

- Messages

- 5

- Reaction score

- 0

- Country

Hello everyone, I'm very much enjoying the knowledge on this forum and I've perused it a far bit over the years. Just to introduce myself, I'm an English architect who studied in the UK, however pretty much all of my practical project experience has been abroad in tropical climates abroad so I'm really not familiar with best practice over here when it comes to technical details.

I'm currently working on an extension at my own home in south east England, which will be constructed in timber frame and vertical clad in narrow GFRC panels (perhaps Equitone or Reider, not sure yet).

Due to site constraints the aim is have the walls as thin as practically possible.

I've drawn up the following wall sections (in plan) with my first attempts at detailing the external walls and would greatly appreciate any feedback.

For wall build up U Values I've been estimating using this tool: .... link removed .....

Which option would be best to go for, or if there would be a better build up I'd love your knowledge and suggesttions.

I should add that, according to my rudimentary calculations the U-Value of all the options is below 0.18.

Another though - for the timber battens and counter battens to the exterior side, would I be best off using a composite ..link removed .... batten rather than wood? They're much more expensive and presumably more durable, however people have been using timber for centuries...

Many thanks!

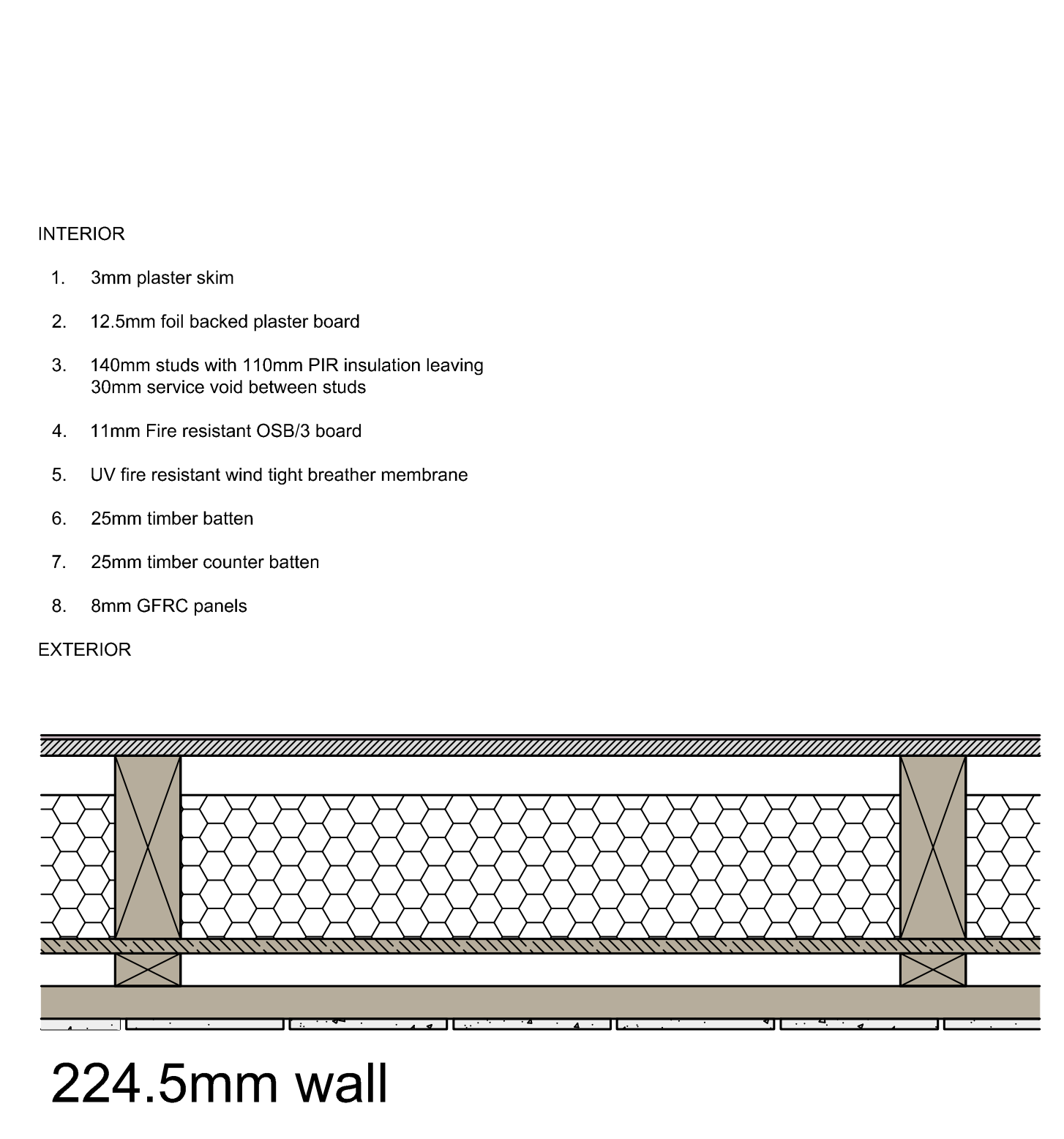

The thin option (224.5mm)

For this option, air-tight electrical boxes would be required as the VCL would be created by the foil back plasterboard, and they would sit behind it. I'm also not sure if this is a definite no-no due to cold bridging through the timber studs directly to the plasterboard. I've seen details online like this though, and would appreciate everyone's thoughts as it allows for the thinnest wall.

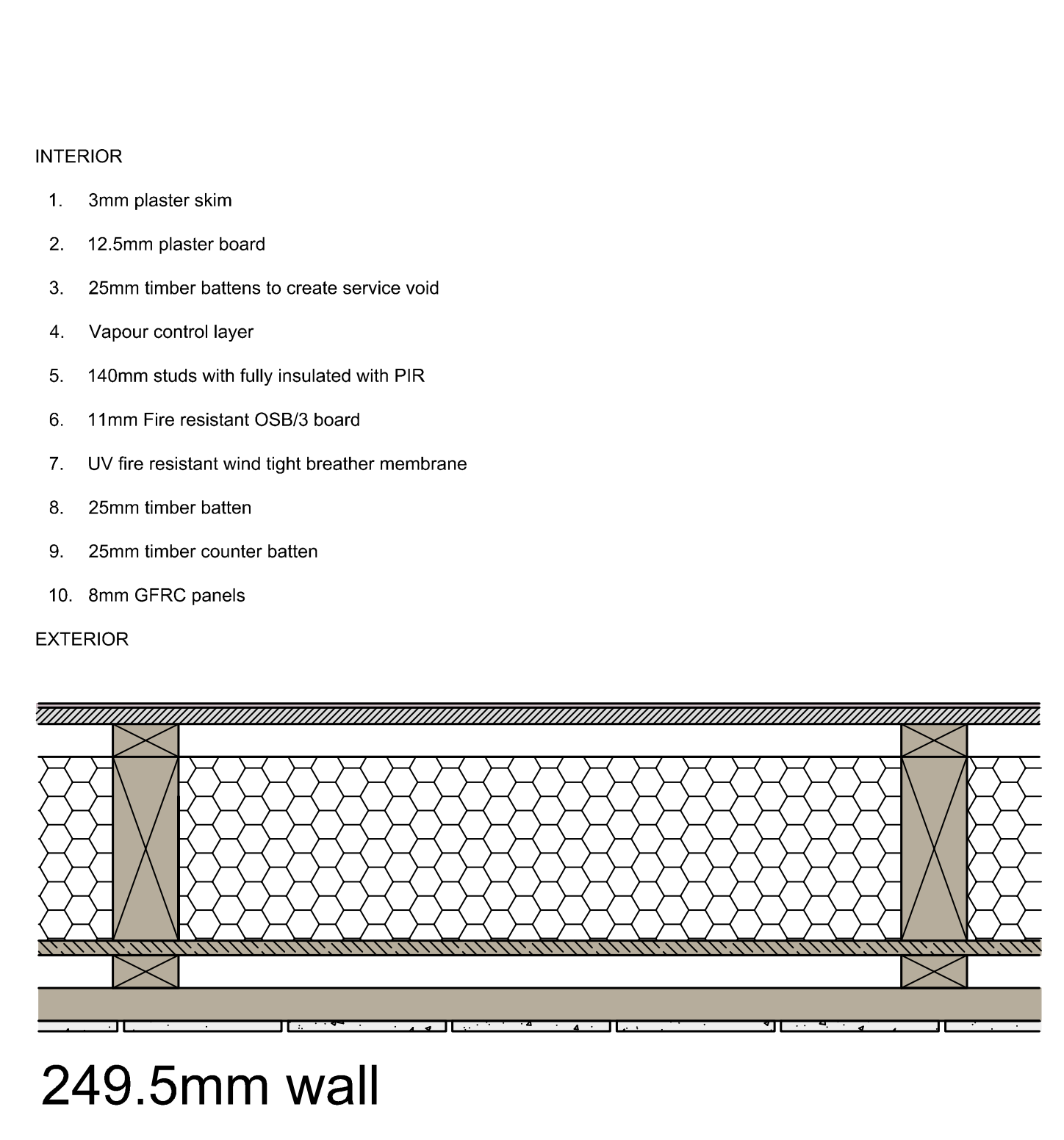

The medium option (249.5mm)

With this option the VCL moves back to the studline and a 25mm service void is created using timber battens.

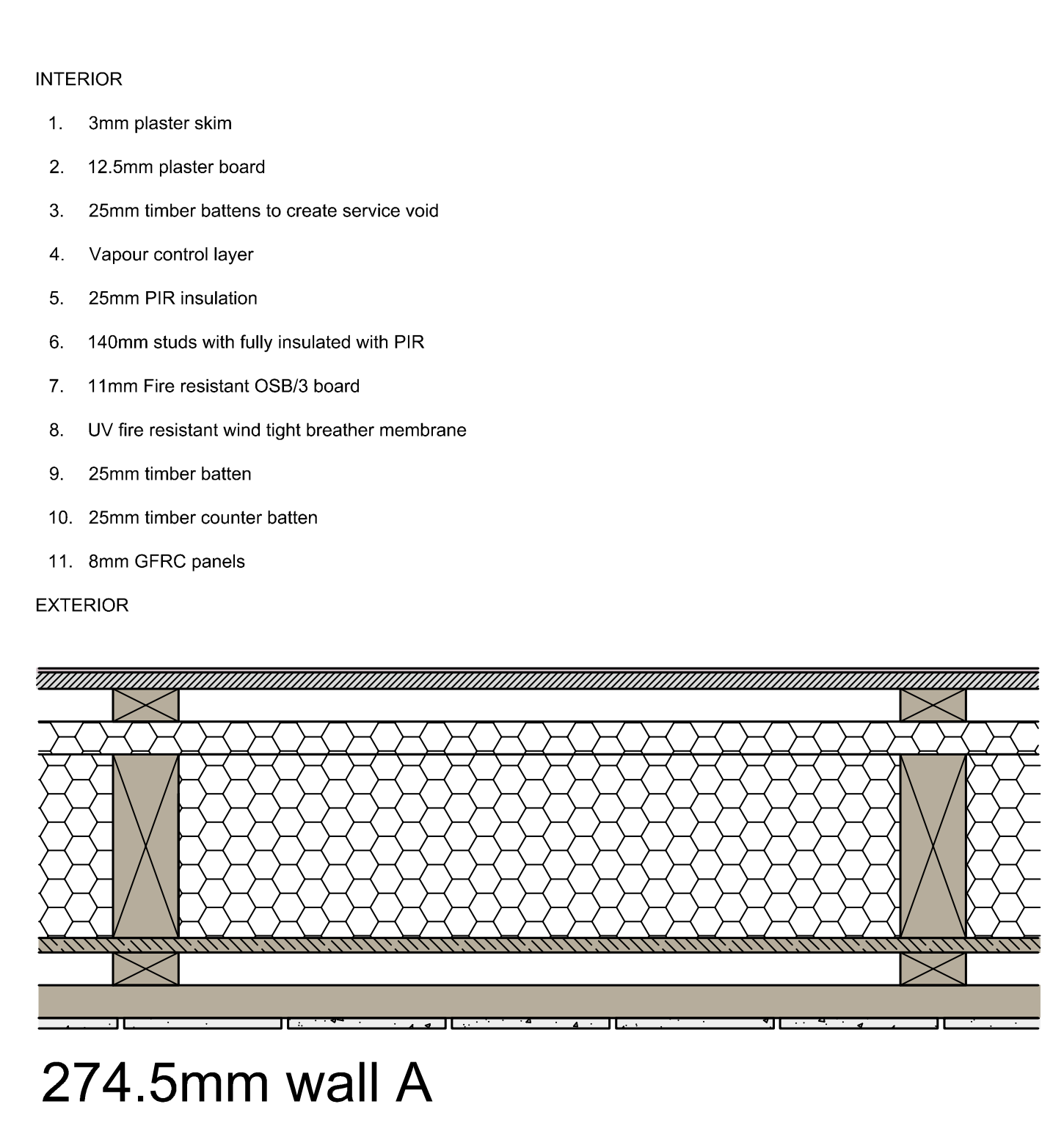

The thick option A (274.5mm)

I've added 25mm PIR between the studs and the service void.

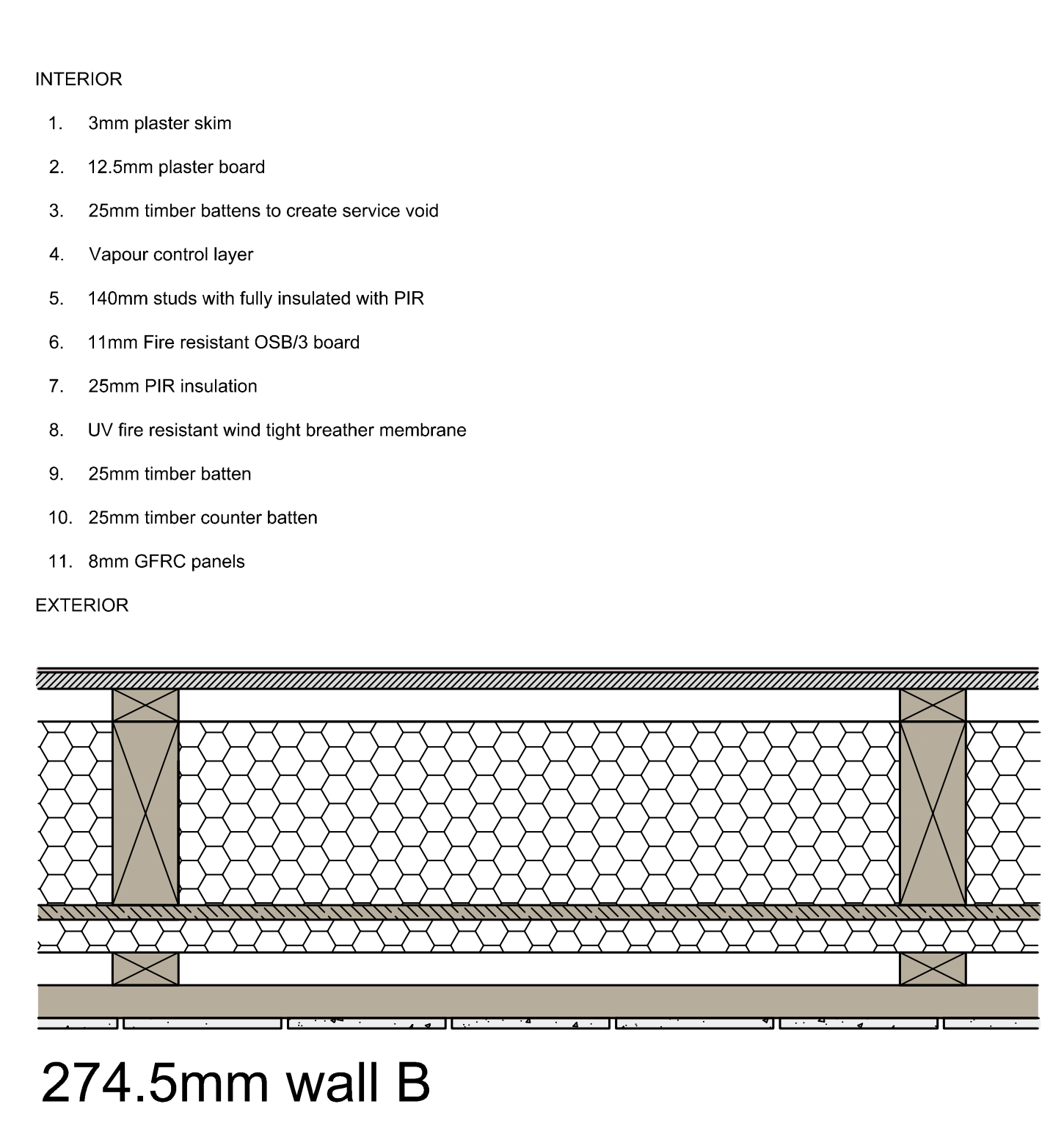

The thick option B (274.5mm)

I've added the 25mm PIR between the studs OSB/3 and the UV membrane

I'm currently working on an extension at my own home in south east England, which will be constructed in timber frame and vertical clad in narrow GFRC panels (perhaps Equitone or Reider, not sure yet).

Due to site constraints the aim is have the walls as thin as practically possible.

I've drawn up the following wall sections (in plan) with my first attempts at detailing the external walls and would greatly appreciate any feedback.

For wall build up U Values I've been estimating using this tool: .... link removed .....

Which option would be best to go for, or if there would be a better build up I'd love your knowledge and suggesttions.

I should add that, according to my rudimentary calculations the U-Value of all the options is below 0.18.

Another though - for the timber battens and counter battens to the exterior side, would I be best off using a composite ..link removed .... batten rather than wood? They're much more expensive and presumably more durable, however people have been using timber for centuries...

Many thanks!

The thin option (224.5mm)

For this option, air-tight electrical boxes would be required as the VCL would be created by the foil back plasterboard, and they would sit behind it. I'm also not sure if this is a definite no-no due to cold bridging through the timber studs directly to the plasterboard. I've seen details online like this though, and would appreciate everyone's thoughts as it allows for the thinnest wall.

The medium option (249.5mm)

With this option the VCL moves back to the studline and a 25mm service void is created using timber battens.

The thick option A (274.5mm)

I've added 25mm PIR between the studs and the service void.

The thick option B (274.5mm)

I've added the 25mm PIR between the studs OSB/3 and the UV membrane

Last edited by a moderator: