- Joined

- 19 Feb 2006

- Messages

- 31,238

- Reaction score

- 10,563

- Country

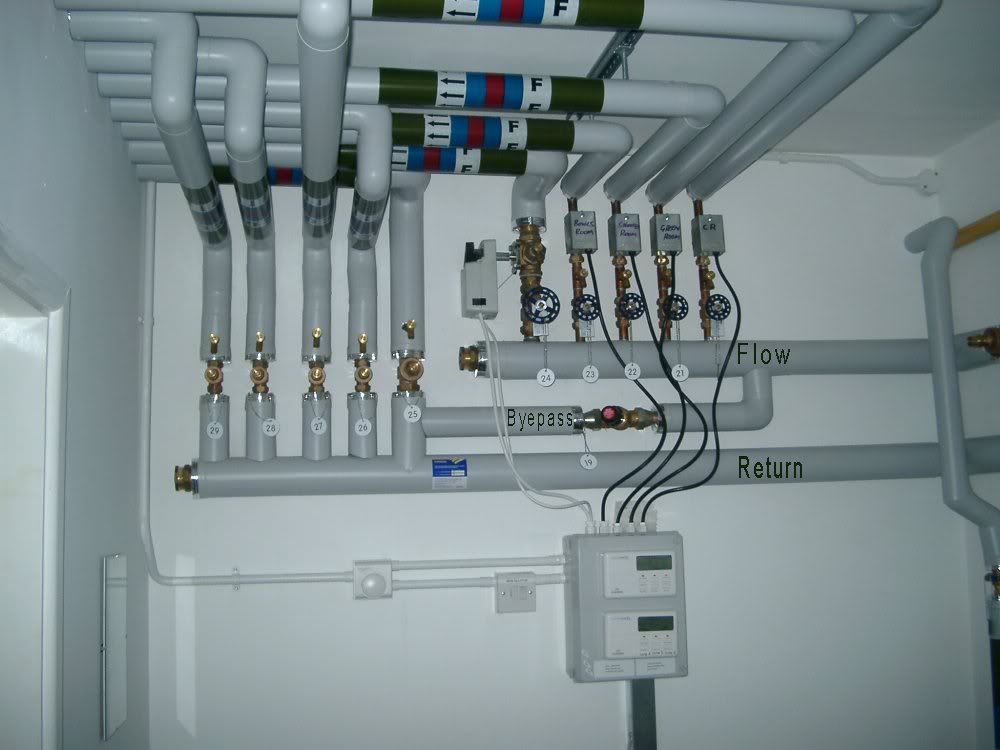

Guys, just a quick question regarding the output side of a low loss header.

What we have is a heat only boiler with in built pump(pump not capable of delivering the flow required), so pipe this into a low loss.

On the output side have two circuits, 1 for heaing (currently 2inch iron)and 1 for hot water each with their own pump and controls.

Would each circuit require a zone valve also to ensure water cannot flow or would just a non return valve and the pump be enough to ensure no flow when no demand called for.

The last time i looked at one of these was as an apprentice so any help would be much appreciated.

What we have is a heat only boiler with in built pump(pump not capable of delivering the flow required), so pipe this into a low loss.

On the output side have two circuits, 1 for heaing (currently 2inch iron)and 1 for hot water each with their own pump and controls.

Would each circuit require a zone valve also to ensure water cannot flow or would just a non return valve and the pump be enough to ensure no flow when no demand called for.

The last time i looked at one of these was as an apprentice so any help would be much appreciated.