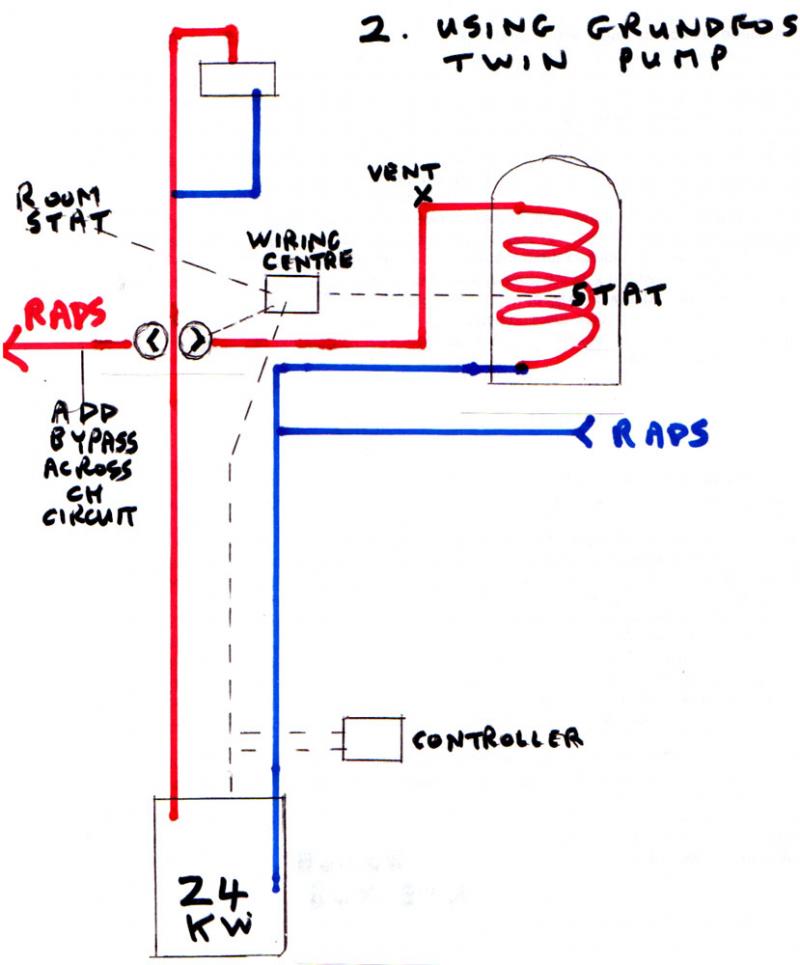

We're wanting to go fully-pumped while doing other work in the bathroom. I'd be VERY REASSURED if you people who know could tell me whether the arrangement in the diagram will work, using a Grundfos twin pump ('Pump Plan').

We have a standard old-fashioned vented system with gravity HW (28mm) and pumped CH (22mm), ground floor 24KW wall-hung boiler, upstairs cylinder. Very little space for replumbing in the boiler cupboard.

I understand the twin pump allows the vent to operate as it should - could easily be offset otherwise. Alternatives were to move existing CH pump onto combined return at the boiler; or to add a second pump on DHW return - but I don't understand the wiring needed.

Grundfos say you have to keep the pumps free of air. How would we do that?

We have a standard old-fashioned vented system with gravity HW (28mm) and pumped CH (22mm), ground floor 24KW wall-hung boiler, upstairs cylinder. Very little space for replumbing in the boiler cupboard.

I understand the twin pump allows the vent to operate as it should - could easily be offset otherwise. Alternatives were to move existing CH pump onto combined return at the boiler; or to add a second pump on DHW return - but I don't understand the wiring needed.

Grundfos say you have to keep the pumps free of air. How would we do that?