Looking for advice on sealing around newly installed windows.

I'd like them to be Air-Tight and Sound-Proof as on a main country town road.

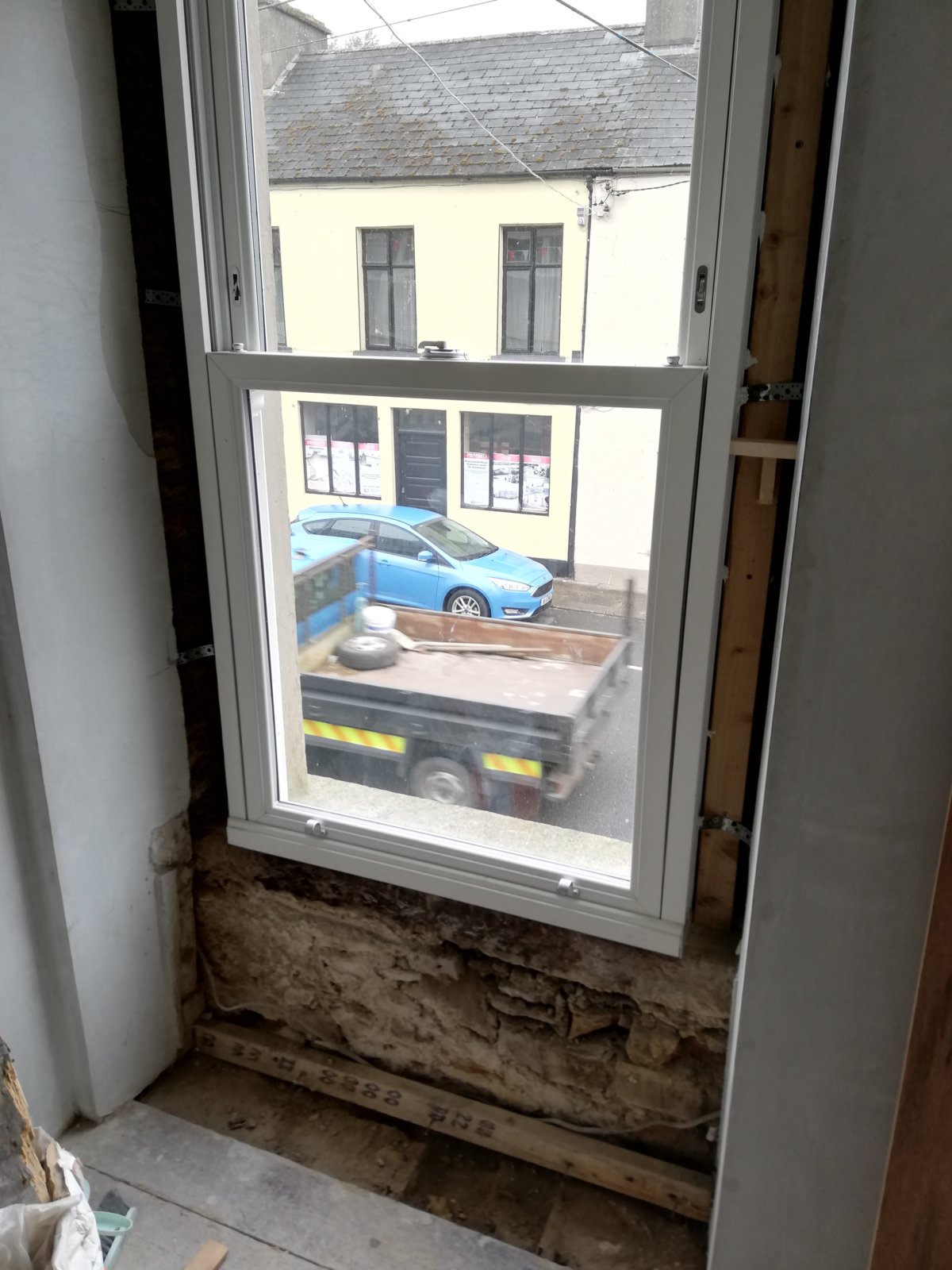

The gap is quite large, as old Sash Windows with weights have been removed. Pics below...

I've been told to avoid Expanding Foam - as it can bow windows? And mine are UPVC Sash Windows, so they need to be able to slide up & down.

If I was to pack them with Rock wool / Fiberglass Insulation I'm guessing the Sound Proofing wouldn't be great?

I've also been told to try Low Expansion Foam as it doesn't expand as much (2:1 ratio) - plus it has a higher density, better soundproofing. But I'm scared to do so as expressed above.

Any advice greatly appreciated. Its a solid stone town house (1820s) - so I want to get it right.

Thanks

I'd like them to be Air-Tight and Sound-Proof as on a main country town road.

The gap is quite large, as old Sash Windows with weights have been removed. Pics below...

I've been told to avoid Expanding Foam - as it can bow windows? And mine are UPVC Sash Windows, so they need to be able to slide up & down.

If I was to pack them with Rock wool / Fiberglass Insulation I'm guessing the Sound Proofing wouldn't be great?

I've also been told to try Low Expansion Foam as it doesn't expand as much (2:1 ratio) - plus it has a higher density, better soundproofing. But I'm scared to do so as expressed above.

Any advice greatly appreciated. Its a solid stone town house (1820s) - so I want to get it right.

Thanks

Last edited: