My boss has just had an "amalgam separator" installed at work - a motorised device for sifting out potentially toxic metals from our waste water before it goes into the drains.

The installation was carried out by a well-known dental equipment supplier, and the total cost was well over £1000.

I think the quality of the electrical work is an absolute f*****g joke

The "electrician" took power from a nearby piece of equipment by "piggybacking" bare blue and brown wires (stripped from 3-core 1.0mm round flex) into its 13A plug. These 2 wires then ran, unsupported, to an enclosed, 100VA step-down/isolating transformer. There was no strain relief where they entered the transformer enclosure, and the transformer's primary fuse was wired into the neutral wire rather than the live.

I told him that this was unsatisfactory, not least because the nurses will have to push their hands past these wires when cleaning the filters. He then said he didn't have any other wire, so I dug him out a secondhand length of 0.75mm 3182Y and suggested he fit that instead - he then spliced that onto the existing blue/brown wires with a "chocbloc" wrapped in insulating tape (also borrowed from the practice)

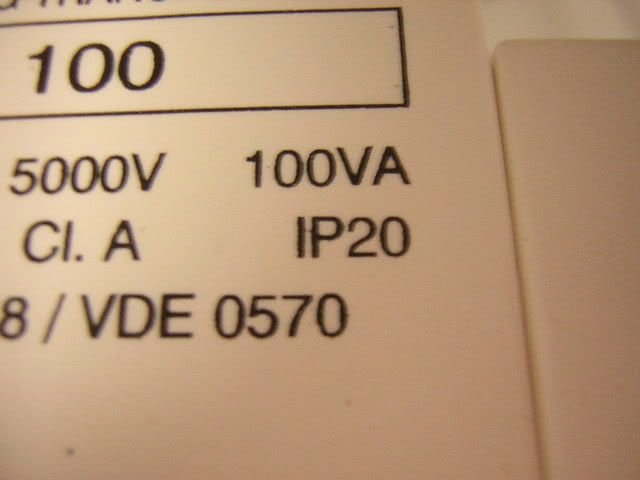

He demonstrated the equipment to me, and showed me where water would be expelled if the filter became blocked - right above the transfomer When I asked him about this, he said it was "waterproof" - even though it clearly says "IP20" on the side

When I asked him about this, he said it was "waterproof" - even though it clearly says "IP20" on the side

There was no PAT (or other electrical) testing carried out.

My question is... What qualifications should this guy have had for this kind of work? And who should we consider reporting this to?

The installation was carried out by a well-known dental equipment supplier, and the total cost was well over £1000.

I think the quality of the electrical work is an absolute f*****g joke

The "electrician" took power from a nearby piece of equipment by "piggybacking" bare blue and brown wires (stripped from 3-core 1.0mm round flex) into its 13A plug. These 2 wires then ran, unsupported, to an enclosed, 100VA step-down/isolating transformer. There was no strain relief where they entered the transformer enclosure, and the transformer's primary fuse was wired into the neutral wire rather than the live.

I told him that this was unsatisfactory, not least because the nurses will have to push their hands past these wires when cleaning the filters. He then said he didn't have any other wire, so I dug him out a secondhand length of 0.75mm 3182Y and suggested he fit that instead - he then spliced that onto the existing blue/brown wires with a "chocbloc" wrapped in insulating tape (also borrowed from the practice)

He demonstrated the equipment to me, and showed me where water would be expelled if the filter became blocked - right above the transfomer

There was no PAT (or other electrical) testing carried out.

My question is... What qualifications should this guy have had for this kind of work? And who should we consider reporting this to?