Bonkersbill,

On the 3 programmer settings you get the following results:

1.CH & HW. All appears to work fine (ie. HW in cylinder & rads warm up to temperature), until cylinder stat is satisfied. Then, the 3PV moves across to CH only and ~ 30secs later boiler overheats and the boiler stat cuts in. - I don't think you've got an 'overheat' stat fitted otherwise the boiler would trip out and would then need manually resetting. Its just the normally thermostat kicking in.

2.HW only. All works fine. Boiler fires, you get HW

3.CH only ~ 30secs later boiler overheats and the boiler stat cuts in.

You’ve confirmed its not a wiring issue when you set the programmer to CH&HW with cylinder stat calling for heat. It was all fine (ie. HW in cylinder & rads warm up to temperature). When you then removed the actuator head off the 3 Port Valve body and manually turned the spindle to CH only position ~ 30secs later the boiler overheats and the boiler stat cuts in. You haven’t changed the state of the circuit yet the fault's occurred. Turn the spindle back to mid position ie. HW&CH, and the boiler fires up assuming either the room stat, or cylinder stat, is still calling for heat (However, the boiler won't fire up instantly mind you, only once the heats pumped out of the boil and the boiler thermostat clicks for heat)

You could with the actuator on call for CH only on the programmer with the room stat calling for heat. (~ 30secs later the boiler will overheat causing the boiler stat to cut in and turn off the boiler). Then remove the head off the actuator and turn the spindle to the mid position. The boiler will fire up and you get heat in the rads (& HW in cylinder will also rise in temp).

Its not a flow restriction. As when you set the programmer to CH&HW with cylinder stat calling for heat, the HW and rads are all fine (ie. HW in cylinder & rads warm up to temperature).

If it was a flow restriction, then the restriction is always there until you physically clear it. However you’re miraculously ‘clearing’ it when you set the programmer to CH&HW with cylinder stat calling for heat. (ie. HW in cylinder & rads warm up to temperature).

You do mention the downstairs rads are possibly not as warm as upstairs. I would balance all the rads first to see if this alters their performance for the better.

The two 15mm down the conduit pipes could very well be supplying some, or all of the downstairs circuit. If its some, look for other boxing. If its a suspended ground floor, the 15mm pipes running down in the boxing next to the boiler could just continue right down and under the floor before going on to the ground floor rads. Or if its a concrete base, the pipes are set in the concrete.

If at some place you can feel these 15mm pipes, switch off all the downstairs rads and with the heating in the CH&HW setting, get someone on command to turn on and off one rad downstairs at a time and feel if any heat travels down one of the 15mm’s and also returns up the other. You’ll then know which rads these 15mm’s are feeding. The pipes run in 15mm could well be undersized (and explain your observation the rads ‘could possibly be hotter’ downstairs), it depends on the combined KW/btu size of the radiators the pipework supplies and the ‘length’ of pipework to them. However, balance all the rads first and see what improvement this makes to the ground floor ones.

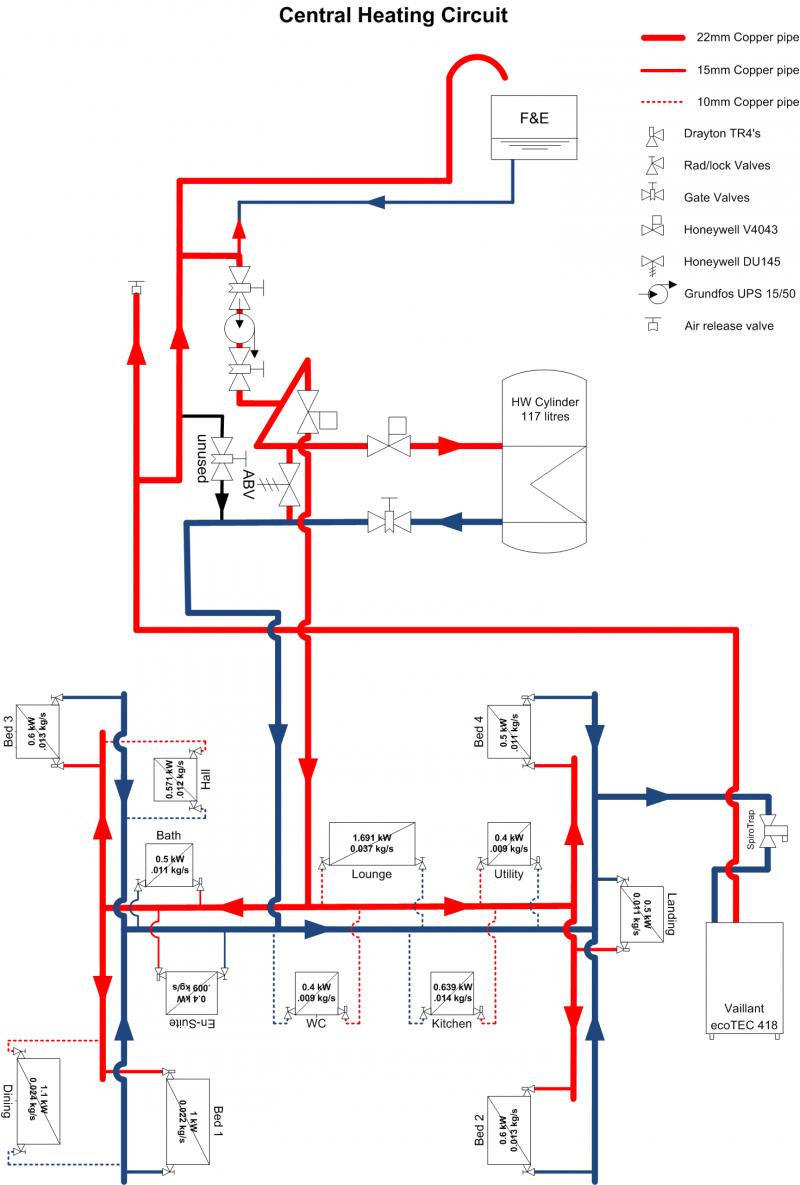

It is a piping issue. You are getting reverse circulation. Its possible someone's tee'd the central heating return pipe into the primary flow from the boiler (ie. The 28mm pipe you’ve identified as running from the boiler to the Grundfos to feed the 3PV.) mistaking it for the return. You will get hot rads as long as the 3PV is in the mid-position. It would also explain why, when the rads are 'working' (ie, only in HW&CH mode), you mentioned the CH circuit feed pipe (the one exiting vertically down from the bottom of the 3PV) isn’t that warm (it should be cooking), as its actually become the CH return from all the rads and the water is flowing up the pipe in reverse into the 3PV and exiting through the HW side to get back to the boiler. Shut the HW exit on the 3PV and there's now no effective circuit to get the heat out the boiler. So it overheats. The boiler thermostat kicks in but it will take a long time for the heat to get out of the boiler and the boiler re-fire as there is no circulation through it. The pump is now circulating water in a loop the correct way through the CH feed, through the rads, through the CH return, into the primary flow... and back to the pump. You may notice a rise in temperature of the CH feed pipe where it leaves the 3PV when this has happened. The boiler is now effectively a dead end off the pump circuit... until the 3PV opens the HW circuit and the water's then pumped through the boiler and immediately reverses direction around the CH circuit.

You need to trace where the CH return is teed into the 28mm pipework. So follow the pair of 28mm pipes back to the boiler. eg remove the boxing cover running down the side of the boiler. Look for previously lifted floorboards running close to the 28mm route prior to it going down the conduit. Try lifting the floorboards right above the conduit. Look into the builder's opening to the sides of the back boiler with a torch. Or get someone Gas Safe registered to remove the fire front to the back boiler to be able to see into the builder's opening more easily (book an early service on the back boiler if it isn't yet due and have a look then). You've got to think they would tee it in prior to the conduit to save materials and time. Also, they're more likely to guess the wrong pipe as the boiler return.

Once you've found the CH 'return' check which 28mm pipe its tee'd on, the hotter (boiler flow) or colder (boiler return). These will be easier to distinguish when the boiler fires from cold. Ideally go right back to the back boiler - the top exiting pipe is the flow (it could be set up flowing the wrong way through the boiler!) Assuming direction of pumped flow through boiler correct, then shift over the CH 'return' run to the boiler return and throttle back the HW gate valve in the middle of pic 1. Then balance your rads. Have a read up about the tee rule on return pipework first. ie. on the return back to the boiler, tee in all rad returns first, then finally tee in the cylinder return.

Must admit I was confused with your title, I thought it was about hydrogen powered central heating and cricket.