I haven't bothered to read all the postings but from what I've seen there's some really basic design issues that aren't being adressed...

Heating design appears very simple but can rapidly get more complex. Proper design is rarely done in a domestic environment for a variety of reasons.... most installers are incapable of the calculations, it takes a considerable time to do all the calculations, without ripping apart an existing installation it can be difficult to work out the pipework (in particular index circuits etc), radiator outputs are difficult to ascertain (especially with old types/styles), building fabric construction can be impossible to ascertain (without knocking holes through walls), manufacturers information is sometimes lacking in detail, technical lines are often hopeless and above all most homeowners simply wouldn't pay for a day(s) of calculator work.

So just a few basic considerations (but leaving out some of the finer points)....

Calculate the heat loss from the house...what the radiators add up to is irelevant, it's the fabric of the building and it's contruction that determines heat loss.

Traditional system design dictated an 11 degree drop accross the radiators/boiler at worst case temperatures ie. at say 18 to 21 degrees room temps and say -1 outside. This 11 degree drop was based on the old Farenheit temperature drop of 20 F and was derived at for a variety of reasons.

Now due to pressure to save energy (pump energy) and modern heat exchanger design (they are often very restrictive) there has been a move away from the 11 degree drop towards a 20 degree drop. Allowing a larger temp drop means the water will be circulating slower and will give off more heat energy as it cools. It also results in an increase in the heat carrying capability of the pipework at the same circulating volume. However, the average temperature of the radiator will drop. If some or all of the radiators have been sized correctly based on the old 11 degree drop then increasing the temperature drop will mean they will give out less heat. This may only be noticable once outside temperatures dip down to freezing. A compromise might be to try an achieve a 15 degree drop.

Once you know the heat loss from each room you can ascertain whether each radiator is sized correctly.

Now you need to calucate the index circuit ie. the pipe run/radiator network with the highest resistance. It's often the furthest/largest radiator.

The head loss (ie. the meter height of water) resistance of the index circuit is dependant on the temperature drop across the radiators/boiler. I suggest you calculate based on a 20 degree drop for now. If the radiators are undersized they will struggle to heat the rooms once it's very cold outside. Calculating at 20 degrees and getting the system working reasonable well is the main aim for the moment. The Vaillant boilers along with other manufacturers have modern heat exchangers with highly restrictive heat exchangers. Without massive circulators achieving an 11 degree drop at worst case scenarios is almost inpossible, a 15 degree drop may be feasible.

With the index circuit calculated we know the maximum head loss (in meters) at the required flowrate (in say litres/hour or cubic meters per hour) of the radiator circuit.

With traditional boilers (say the old cast iron and many copper) resistance through the boiler could be ignored. With most cast iron the waterways were huge, with copper fabrications it was simply a few copper pipes. With these boilers we could simply look at a pump chart, find the flowrate along X axis, find the index circuit head loss along the Y axis and see where the lines intersect. If the point was below the speed curve selected the circulator was suitable. For the majority of domestic properties a 5 or sometimes 6 meter circulator was suitable (since heat exchangers had little friction) and as a result calculations of index circuits were largely redundant.

As mentioned before, the latest generation of boilers have heat exchangers of a completely different design than the old cast iron and copper fabricated designs. They are either manufacturered from stainless steel formed tubing or cast aluminium. In order to increase the heat transfer and reduce the physical size/weight the waterways are incredibly fine. In the case of the Giannoni fitted to the Vaillant, the heat exchanger approximates three 12mm (a bore only 10mm) soft copper tubes connected in parrallel perhaps around 1.5 meter in lenght. If this was bad enough they are formed into a tight spiral, the boilers internal pipework is often only 18 to 22mm diameter tube containing multiple tight bends. Trying to circulate water through heat exchanger as a rate to allow us to have the traditional 11 degrees drop would require a massive pump. Even circulating water at a slower rate to achieve a 20 degree drop still results in a significant head loss.

Therefore the headloss through the heat exchanger MUST be taken into account. Unfortunately most installers fail to understand this and most manufactures pay scant regard to this problem either. It's in part due to the cover up about condensing boilers...ie. that they no more difficult to install than the older boilers. Of course it's anything but when you have to use commercial pumps or low loss headers in a domestic environment and have an installer base that has little design knowledge (or even care).

There's a simple calculation to provide the flowrate at a particular temperature drop and heat output.

Flowrate in litres/second = Kw output / (4.2 x temperature drop)

For the flowrate in litres per minute obviously multiply by 60 or litres per hour by 3600.

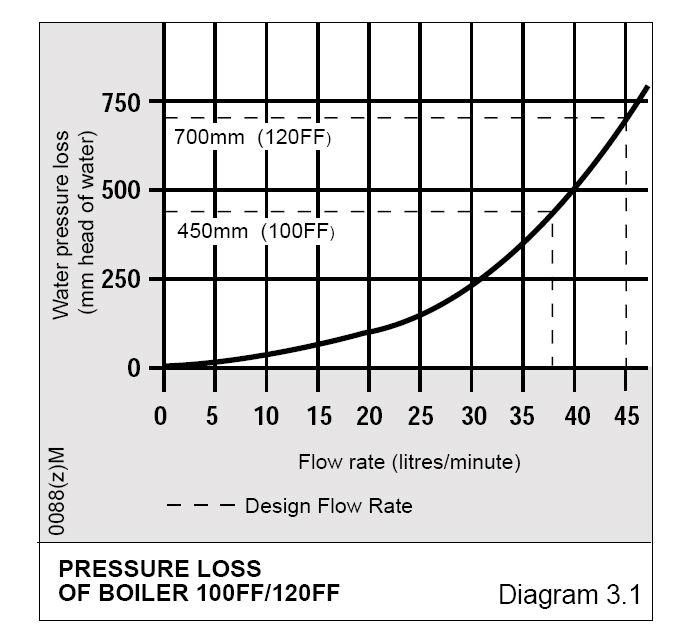

Just as an example here's the headloss graph for an old Glowworm Ultimate heat exchanger. The 120,000 Btu is around 35 Kw (so similar to your Vaillant). The dotted line from the 120FF shows the flowrate (45 litres/min) at the traditional 11 degree drop and a corresponding head loss of just under 0.75 m. However if we recalculate at 20 degrees drop the flowrate will be 25 litres/min and a head loss of 0.25 m.

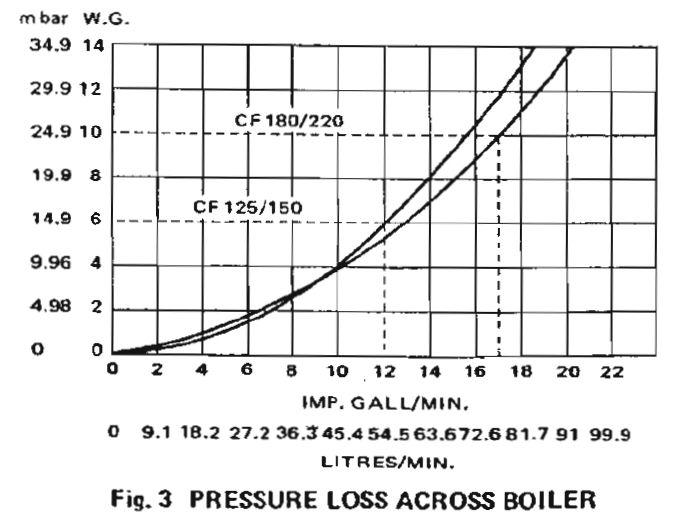

Now plug a 20 drop across the ancient Potterton CF125/150 heat exchanger and at a similar Kw output we get a head loss of under 0.05 m!

Now compare these old heat exchangers to your modern Vaillant....

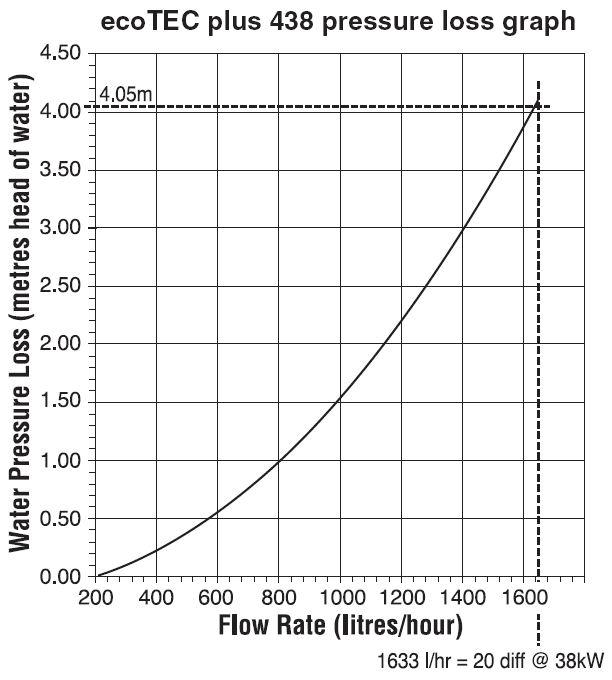

At the 20 degree drop and the boiler output of 38 Kw we get a flowrate of 1628 litres/hour (approx). Look at the heat loss...it's massive at 4 m.

If we recalculate at 15 degrees we are off the scale and the head loss is vast, at 11 degrees...forget it. This is just another part of the great condensing boiler cover up, the public and installers have been conned into thinking modern boilers are reliable and easy to install compared with the older generation boilers.

http://www.anchorpumps.com/media/downloads/75/Grundfos Light Commercial Circulators.pdf

So if we take a standard UPS 15 60 a 6m domestic circulator and look at the pump diagram we can see it will barely circulate the required water volume through the heat exchanger. At 20 degrees drop, 1633 litres/hr is 0.45 litres/second. Follow the flowrate up from the X axis on the pump diagram until it hits the curve at speed 3. Going horizontally from that point it hits the Y axis at about 3.5m. So at that flowrate it can only overcome a head loss of 3.5m. There is no spare capacity to overcome the system index circuit.

With the UPS 25 55 looking at the pump graph at 0.45 litres/min it provides a head of 4 meters...a little more than the "domestic" pump. So it would be sufficiently powerful enough for the flowrate through the boiler at a 20 degree drop but again not once the additional index circuit is added. Of course this is a second hand pump so its actual performance is debatable.

So with the boiler head loss diagram and the index circuit calculated the overall flowrate and head loss can be derived. It's then just a case of matching a pump(s) to the system.

Ignoring low loss headers (it gets much more complicated) the option either is one large pump or a couple of pumps in series. Larger pumps greater than domestic duty rapidly increase in cost so it can be more cost effective to use muliple pumps in series (where the head figure at a given flowrate can be added together).

Adding both pumps together in series as you have done for the downstairs circuit would appear to have gone someway to solving the circulation issue. So the cheapest option for now is to move the new UPS 15 60 pump and connect it next to the UPS 25 55 so that all zones are operating with both pumps.

As has been mentioned (after the usual nonsense has been posted) the first figure on a Grundfos pump refers to the nominal bore of the pump, the second figure refers to the approximate maximum head in meters (AT NO WATER FLOW so is irrelevant), and where qouted the third figure is the mm distance between fittings. Most domestic are 130mm and commercial 180mm.

Just a few other points...

There should be a lockshield valve fitted to the cylinder primary pipework in order to restrict the flow rate when the heating circuits are operational.

Balance the system to achieve the same temperature drop across all the radiators/cylinder.

Hopefully the basic pipework is reasonably well sized for the heat loads and lenght.

It's benefical to run the boiler flow temperature lower that it's maximum but it needs to be sufficent to heat the cylinder to 60 degrees. Only when outside temperatures are severe will the temperature need to be increased to maximum (if the radiators were sized with high flow temperatures). This iss where they are some benefits in oversizing radiators since they wil still give off sufficient heat when average rad temperatures are lower.

Forget any suggestions of changing boiler circuit boards or weather compensation controls....you have to get the basics right first.

Make sure the system is dosed correctly with inhibitor, moedrn heat exchangers are less tolerant to corrosion and scale/sludge. Once they block the boiler is often a write-off.

It may be winter before you can really ascertain whether you can achieve the desired temperature drop and if at that drop the average radiator temperature is sufficient to heat the rooms. At this time of year when outside temperatures are rarely dropping below 10 or 12 degrees (certainly in London) at night, you can't judge whether the system is really going to work until it's snowing. Many installers install new boilers in the warmer months and leave what appears to be a working system (all rads heat up nicely) but come the winter it fails to heat the house up simply because the water is not being circulated in sufficient volume and the raidators dissapate more heat.