Matt

Ps what you have overlooked is hinted at in my post before this one

Sorry Mattle you'll have to explain.

FWIW Mattle i have a great deal of respect for you , this is from someone in a previous guise.

Well since you asked nicely I will explain

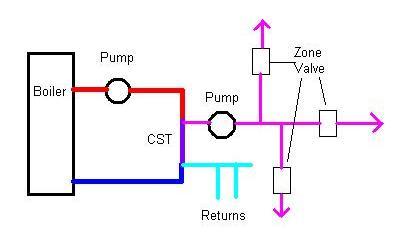

Let us say that the op decides to go for hydraulic separation between the boiler and the system and installs a LLH

He finds that by pure chance the spacing between the flow and return is such that all he has to do is cut out 2 sections of pipe and slot the LLH straight in, happy days!

so he gets himself a suitable pump to fit on the Primary and fits It

He then learns that because of the fact it now doesn't have to pump through the boiler its now suitable as the secondary Pump even more happy days

Now

That's all he has to do mate!

he has got a perfectly working S-Plan system (think of the LLH as a heat because, thats what it is)

no

need in his case for two secondary pumps,nor check valves etc

He may need to tweek the auto bypass but thats already installed and it would need tweaking anyway but the boiler or boiler pump dont need it

OP pleased and the Boiler as happy as larry

all a Low loss header is,is a packaged set of "closely spaced tees" with some nice extras thrown in the working principle is the same

That took me bloody ages!

Matt