The only advantages, that I can think of, of a LLH is that you can fit an air vent at the top and a drain tap at the bottom.I'm not disputing that although the LLH does have an advantage over the CST (think about it).

Oh, yes, there is another a secondary flow can be some distance from its return, so several flows can be at one end and their returns at the other.

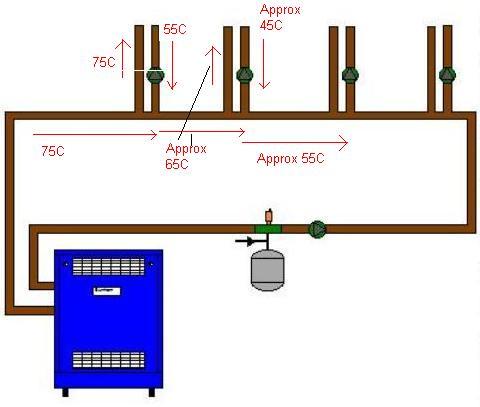

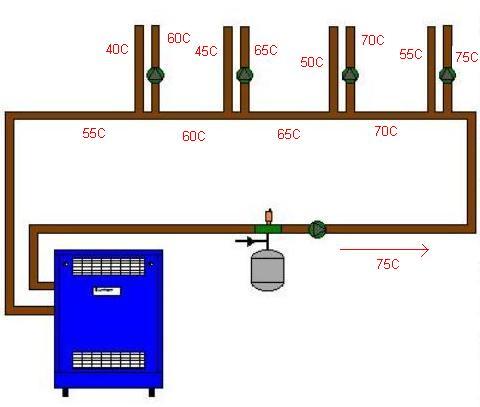

Not sure what you mean by 'series' and 'parallel' in this context.Not at all , using the 'parallel' P/S circuit (crossover) ensures ALL 'secondary' loads recieve the same water temperature (not to be confused with the series P/S circuit)

That doesn't answer my question: what is wrong with it?I think the boiler/llh/buffer manufactures would take a dim view of this type of set-up