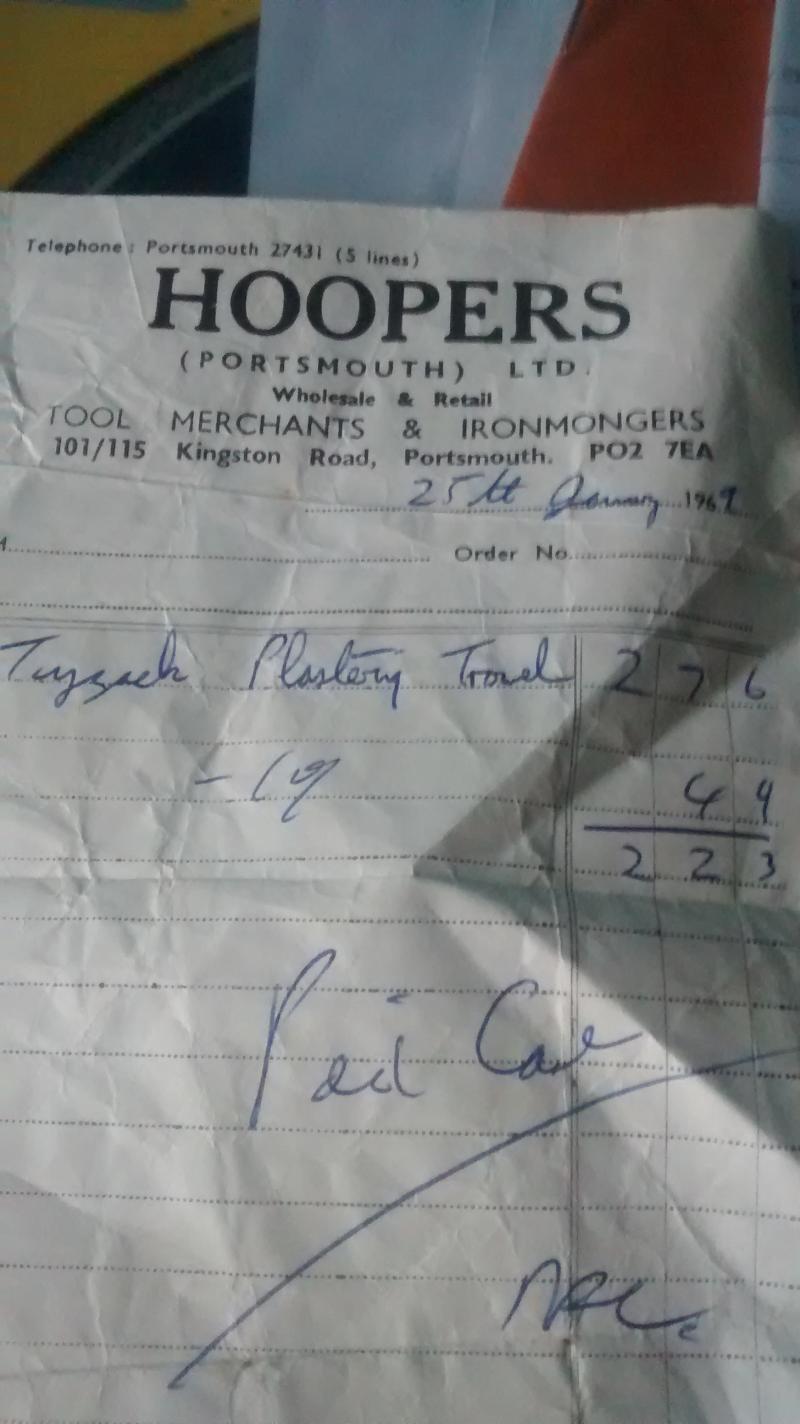

Going through my old mans things I found this receipt from 1969 for a tyzack just thought I would share it as I found it interesting

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

can you remember how much a trowel was in 1969?

- Thread starter stevethespreader

- Start date

Brilliant Steve.

. I'll have to ask my old man.

Two pound seven and six? About £35 now?

A pint was 1/8 about £1.26 now.

. I'll have to ask my old man.

Two pound seven and six? About £35 now?

A pint was 1/8 about £1.26 now.

I found it in a suitcase mic inside an envelope not sure why he kept it but I have the trowel as well its not much use now though , I can't remember how much a pint was in 69 lol 1/8 is that 1 shilling and 8 d?Brilliant Steve.

. I'll have to ask my old man.

Two pound seven and six? About £35 now?

A pint was 1/8 about £1.26 now.

think he was on top money then it was something like £28 a day if I member right don't quote me on it though but that's the figure I was told, he done OK as a spread he saved up and bought his house cash in 1969, it was £1550 you will be hard pressed to do that nowdaysAnd in 1969 he might have been earning about £30 a week.

Great to see that old receipt Steve. Most plastering tools, trowels, guagers, twitchers etc then were made by Tyzack/Spear and Jackson. I bought an 11 inch Tyzack 216 pattern, stainless steel trowel in 1974 up here in Scotland. I can't remember how much I paid for it, but I still have it to this day. It's not in a useable condition plastering wise, but I still use it for scraping/cleaning up etc. My main trowel now is a 13" stainless Tyzack, along with an 11" Ragni stainless. As Micilin said earlier, you'll pay a lot more now for a decent trowel, even though £2-7s-6p was a lot of money then.

my old mans was 11 in and is no good as well the blade got so thin it kept getting nicks in and the nice edge it had has gone so its just a relic now, all my trowels are my mt except for bobs old tyzac which he gave me when he retired first the I've heard of a pattern 216? What's that mean?Great to see that old receipt Steve. Most plastering tools, trowels, guagers, twitchers etc then were made by Tyzack/Spear and Jackson. I bought an 11 inch Tyzack 216 pattern, stainless steel trowel in 1974 up here in Scotland. I can't remember how much I paid for it, but I still have it to this day. It's not in a useable condition plastering wise, but I still use it for scraping/cleaning up etc. My main trowel now is a 13" stainless Tyzack, along with an 11" Ragni stainless. As Micilin said earlier, you'll pay a lot more now for a decent trowel, even though £2-7s-6p was a lot of money then.

I started plastering in 1964 at Huntspond Road,Tichfield, in Hampshire,and bought nearly all my tools in Gosport, Hampshire. God knows how much I paid for them 50 years ago, but there was one tool I never bought way back then, and that was a hawk.

It was home made, constructed out of plywood. Most plasterers in those days used the same. I never saw an aluminium hawk until years later. We made our own wooden floats too, out of yellow pine, the same as our darbies.

I still have a wooden yellow pine float that I never let dry out, and I also still use a yellow pine darbie made from an old piece of skirting from a bank.

Anyone remember the "cross grain float" too,,, Good old days.

It was home made, constructed out of plywood. Most plasterers in those days used the same. I never saw an aluminium hawk until years later. We made our own wooden floats too, out of yellow pine, the same as our darbies.

I still have a wooden yellow pine float that I never let dry out, and I also still use a yellow pine darbie made from an old piece of skirting from a bank.

Anyone remember the "cross grain float" too,,, Good old days.

The 11" Tyzack stainless trowel had "216 pattern" printed into the metal on the topside of the trowel. I think it was a trademark for that particular trowel/model Steve.

As a matter of fact, I've just Googled it, and you can still get the Tyzack 11" Stainless 216 pattern to this day, have a look.

As a matter of fact, I've just Googled it, and you can still get the Tyzack 11" Stainless 216 pattern to this day, have a look.

OK ta just a mention about the Ali hawk some spreads claim they are no good for your trowel what doyou think ? I use plasticThe 11" Tyzack stainless trowel had "216 pattern" printed into the metal on the topside of the trowel. I think it was a trademark for that particular trowel/model Steve.

I agree about the aluminium hawk. Although I use one nowadays, i'm still very careful/wary about damaging my trowel on the edge of the hawk. They can bend slightly out of shape as well if not looked after. I remember you said you were getting a plastic hawk Steve.

Same here on the hawk, although I have used an Ali one for years now.

Also we used to make our own plungers by bending reinforcing steel and tying mesh on, f we didn't have a bike sprocket to weld on .

Pirana pine float.

Also we used to make our own plungers by bending reinforcing steel and tying mesh on, f we didn't have a bike sprocket to weld on .

Pirana pine float.

I don't like the Ali ones the lightweight plastic one from band q is good.I agree about the aluminium hawk. Although I use one nowadays, i'm still very careful/wary about damaging my trowel on the edge of the hawk. They can bend slightly out of shape as well if not looked after. I remember you said you were getting a plastic hawk Steve.

I would like to see one of those homade wisks michSame here on the hawk, although I have used an Ali one for years now.

Also we used to make our own plungers by bending reinforcing steel and tying mesh on, f we didn't have a bike sprocket to weld on .

Pirana pine float.

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 3

- Views

- 2K

- Replies

- 3

- Views

- 3K

- Replies

- 3

- Views

- 3K

S