- Joined

- 13 Mar 2019

- Messages

- 1,287

- Reaction score

- 328

- Country

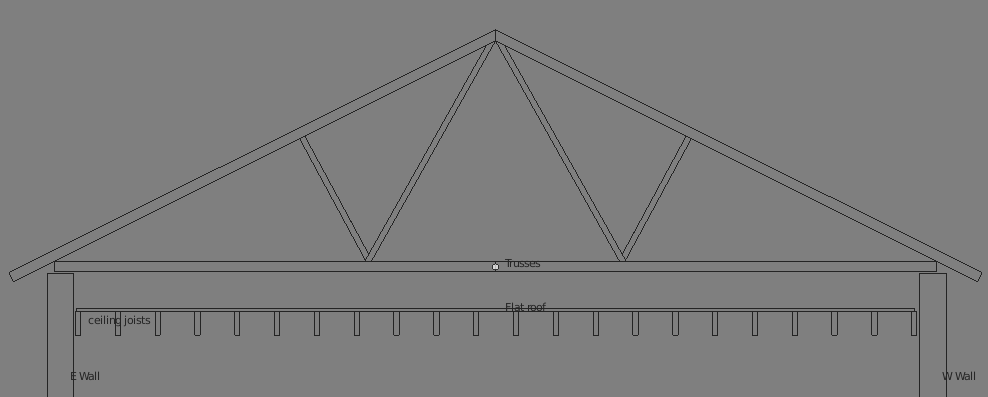

Fink/"W" trusses on ~500mm centres. Old ply flat roof about 350mm below. The bottom chords are 34x95mm section and about 8m long:

How much load can the bottom chords take as-is? The intention is to board it out and use it for storage.

If the answer is "they won't even support the weight of some boarding" or similar, I assume I'll be able to put some props between the bottom chords and the flat roof to increase the maximum loading. I am only really interested in loading the central "A" as the outer sides will be awkward to get to.

How much load can the bottom chords take as-is? The intention is to board it out and use it for storage.

If the answer is "they won't even support the weight of some boarding" or similar, I assume I'll be able to put some props between the bottom chords and the flat roof to increase the maximum loading. I am only really interested in loading the central "A" as the outer sides will be awkward to get to.