I have a problem with the boiler short cycling when the flow temperature is any lower than around 75 degrees. It's a Unica 32HE with Siemens RDJ10RF room stat set to 19.5 degrees (baby in the house).

The thermostat correctly calls for heating if the room temp is outside the range 19 and 20 degrees (+/- 0.5 degrees from 19.5 setpoint). The receiver responds accordlingly, and the boiler fires up correctly. No problems there. Once the call for heat has stopped at 20 degrees, inertia in the system takes it up to 20.5 degrees which is ok. The thermostat works fine. It's not in a draughty cold area, or on a radiator. All TRVs are fully open except a towel rail which is half open. 8 rads in a single storey cottage, all twin panel with fins, with another one being a cast iron thing in a bathroom with no TRVs, just 'tap handles' at each end which are open a hair (rad gets red hot). The system is big copper pipes to a manifold, and then each radiator looks to have it's own microbore flow and return from the manifold.

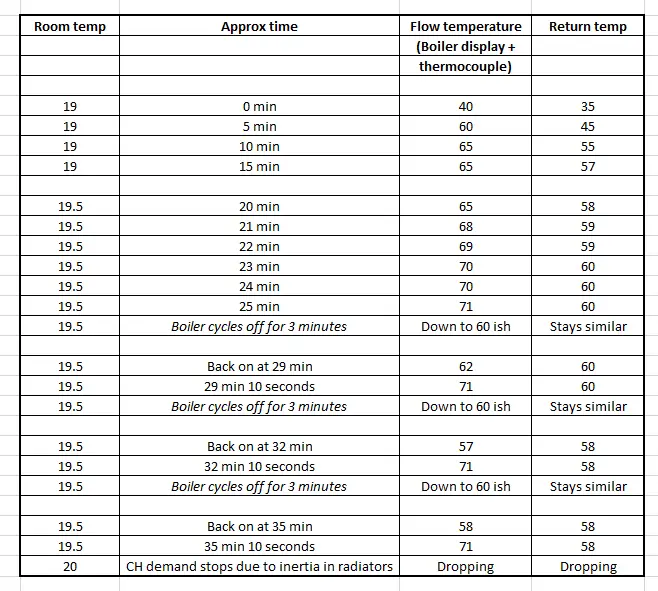

The CH flow temperature is set to 65 degrees. When the heating first kicks in at an air temp of just under 19 degrees, the return temperature rises to 55 degrees (just about condensing). Temperatures were measured on the flow and return copper pipes under the boiler with two known good thermocouples. The flow pipe matches the boiler display exactly.

As time goes on the room temperature increases quite rapidly, the return temperature increases to about 60 degrees (not condensing anymore), and then the flow temperature further increases to 71 (set point + hysteresis) and the boiler cuts out and starts cycling. At this point the room stat is still only on 19.5. The boiler cycles off for 3 minutes, then fires up. Then off again after about 10 seconds, etc etc.

Before it start short cycling I can hear the boiler modulating to a lower burn to try to maintain the set flow temp of 65 degrees, but it's a losing battle. I imagine it can only modulate so low before it has no choice but to turn off at 71.

During this cycling it fires for about 10 seconds, in which time the flow goes from whatever it's dropped to (around 60) straight up to 71 and cuts out again, within seconds. I can hear it try to modulate within that 10 seconds, but it's not enough to catch it before it cuts out again. Three minute delay and then repeat again and again. If there wasn't as much intertia in the system it would carry on doing this and the room may never reach the upper limit of the demand temperature on the room stat (19.5 + 0.5). As it is, the inertia in the rads gets the air temp up to 20.5 degrees and the demand for heat stops at a hair over 20. If I turn the boiler off when it starts cycling, the room will still reach 20.5 just on inertia, without the cycling.

If I increase the flow to 75 it behaves correctly, with no cycling. The downside of this is roasting hot radiators (unsafe for child) and high return tempertures (not condensing). Maybe ok in winter to heat up quickly after work, but not now in warmer conditions when I want a constant 18/19 degrees inside. I want the flow temperature to be around 55 or 60 degrees.

When I turn the flow down to 60 the above cycling problem is worse. It starts cycling earlier on, and in this case won't achieve the desired room temp. At 75 it works ok. Also, at 60 I get a nice plume from the flue (until it short cycles), which is absent at 65 or 75 degrees for most of the time.

Where do I go from here to achieve the flow temperature (and suitable return temp for condensing) that I want, without short cycling? I would be happy if the rate at which the house heats up was slower during the summer. At the moment it ramps up fast and cools over a few hours. I would like a more continual 'slow burn' so the rads are warm for longer, rather than scorching hot for a short time, which I think is also more efficient for the boiler too. If possible...

Because my essay probably isn't particularly clear, I've put some numbers below. I'd be really grateful for some pointers of how to achieve my goals and save a bit of cash on efficient boiler operation! Thanks.

Flow set at 65 degrees:

The thermostat correctly calls for heating if the room temp is outside the range 19 and 20 degrees (+/- 0.5 degrees from 19.5 setpoint). The receiver responds accordlingly, and the boiler fires up correctly. No problems there. Once the call for heat has stopped at 20 degrees, inertia in the system takes it up to 20.5 degrees which is ok. The thermostat works fine. It's not in a draughty cold area, or on a radiator. All TRVs are fully open except a towel rail which is half open. 8 rads in a single storey cottage, all twin panel with fins, with another one being a cast iron thing in a bathroom with no TRVs, just 'tap handles' at each end which are open a hair (rad gets red hot). The system is big copper pipes to a manifold, and then each radiator looks to have it's own microbore flow and return from the manifold.

The CH flow temperature is set to 65 degrees. When the heating first kicks in at an air temp of just under 19 degrees, the return temperature rises to 55 degrees (just about condensing). Temperatures were measured on the flow and return copper pipes under the boiler with two known good thermocouples. The flow pipe matches the boiler display exactly.

As time goes on the room temperature increases quite rapidly, the return temperature increases to about 60 degrees (not condensing anymore), and then the flow temperature further increases to 71 (set point + hysteresis) and the boiler cuts out and starts cycling. At this point the room stat is still only on 19.5. The boiler cycles off for 3 minutes, then fires up. Then off again after about 10 seconds, etc etc.

Before it start short cycling I can hear the boiler modulating to a lower burn to try to maintain the set flow temp of 65 degrees, but it's a losing battle. I imagine it can only modulate so low before it has no choice but to turn off at 71.

During this cycling it fires for about 10 seconds, in which time the flow goes from whatever it's dropped to (around 60) straight up to 71 and cuts out again, within seconds. I can hear it try to modulate within that 10 seconds, but it's not enough to catch it before it cuts out again. Three minute delay and then repeat again and again. If there wasn't as much intertia in the system it would carry on doing this and the room may never reach the upper limit of the demand temperature on the room stat (19.5 + 0.5). As it is, the inertia in the rads gets the air temp up to 20.5 degrees and the demand for heat stops at a hair over 20. If I turn the boiler off when it starts cycling, the room will still reach 20.5 just on inertia, without the cycling.

If I increase the flow to 75 it behaves correctly, with no cycling. The downside of this is roasting hot radiators (unsafe for child) and high return tempertures (not condensing). Maybe ok in winter to heat up quickly after work, but not now in warmer conditions when I want a constant 18/19 degrees inside. I want the flow temperature to be around 55 or 60 degrees.

When I turn the flow down to 60 the above cycling problem is worse. It starts cycling earlier on, and in this case won't achieve the desired room temp. At 75 it works ok. Also, at 60 I get a nice plume from the flue (until it short cycles), which is absent at 65 or 75 degrees for most of the time.

Where do I go from here to achieve the flow temperature (and suitable return temp for condensing) that I want, without short cycling? I would be happy if the rate at which the house heats up was slower during the summer. At the moment it ramps up fast and cools over a few hours. I would like a more continual 'slow burn' so the rads are warm for longer, rather than scorching hot for a short time, which I think is also more efficient for the boiler too. If possible...

Because my essay probably isn't particularly clear, I've put some numbers below. I'd be really grateful for some pointers of how to achieve my goals and save a bit of cash on efficient boiler operation! Thanks.

Flow set at 65 degrees:

Last edited: