Our building has a solid wooden boarded roof (spruce planks).

We'd initially planned to nail shingles through 50mm PIR directly onto the roof boards, and had been advised this wouldn't need a DPM since the roof is warm?

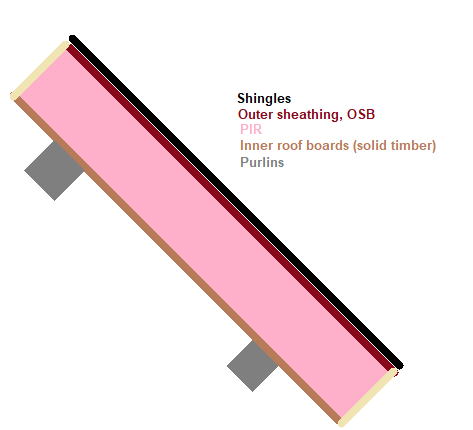

But we are now leaning towards a 'sandwich' design with a frame and outer OSB layer on top.

Probably 75-100mm PIR, potentially more. Roof boards are 19mm, OSB specced at 18mm I think.

No air gap planned.

I am trying to figure out of we need DPM - is there going to be a condensation risk? Have had conflicting advice. If so, where should it go in my diagram? I thought the point of the insulation is it prevents an abrupt temperature gradient leading to condensation.

If it's needed is it a fancy (expensive) product or just something bog standard like this: https://www.screwfix.com/p/capital-...amp-proof-membrane-black-1000ga-15-x-4m/22842

We'd initially planned to nail shingles through 50mm PIR directly onto the roof boards, and had been advised this wouldn't need a DPM since the roof is warm?

But we are now leaning towards a 'sandwich' design with a frame and outer OSB layer on top.

Probably 75-100mm PIR, potentially more. Roof boards are 19mm, OSB specced at 18mm I think.

No air gap planned.

I am trying to figure out of we need DPM - is there going to be a condensation risk? Have had conflicting advice. If so, where should it go in my diagram? I thought the point of the insulation is it prevents an abrupt temperature gradient leading to condensation.

If it's needed is it a fancy (expensive) product or just something bog standard like this: https://www.screwfix.com/p/capital-...amp-proof-membrane-black-1000ga-15-x-4m/22842