Got a bit of an issue with a newly installed UFH system on an existing S Plan with system boiler & unvented cylinder.

The UFH has been added to a new first floor of the property which includes rads in the rooms without UFH. A branch has been taken off the 28mm flow and return from the boiler to the first floor in 22mm.

The 22mm flow tees off to separate zone valves for UFH and the rads. The return from both the rad circuit and UFH manifold tee into a 22mm return within one metre of each other back down to the basement where the boiler is.

The 1st floor rad circuit works great, and electrically all valves/stats etc work as they should. The problem is with the UFH manifold, this has 7 circuits(4 zones) and I'm struggling to get a decent flow or pressure so the UFH pump will feed all the circuits effectively.

I raised the pressure at the fill point in the basement to 1.5bar. At the UFH manifold on the 1st floor it reports just over 1bar which I assume is due to the greater pressure of water in the circuit in the basement.

When I run the UFH on its own (even with just 1 circuit) I seem to be getting reverse flow through the 1st floor rad circuit and the UFH doesn't heat up or very little. Is this because the return from the UFH manifold & 1st floor rad circuit are too close together?

I tried raising the Wilo UFH pump speed (is currently set to 1) but it gives a red/green LED error on the pump. Have bled multiple times also and circuits all pressure tested ok. Also re-flushed to remove any residual air.

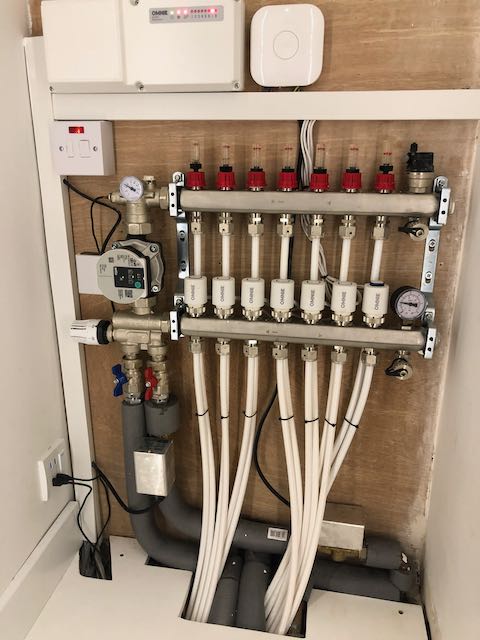

Below is a pic of the manifold. In the centre at the bottom is the 22mm feed (flow) from the main boiler circuit in the basement. This tees left to the UFH manifold with zone valve and off to the right with zone valve for the 1st floor rad circuit.

The return from the UFH manifold is on the far left and this goes under the floor where it then tees into the return from the rad circuit before heading back down to the basement return to the boiler.

The UFH has been added to a new first floor of the property which includes rads in the rooms without UFH. A branch has been taken off the 28mm flow and return from the boiler to the first floor in 22mm.

The 22mm flow tees off to separate zone valves for UFH and the rads. The return from both the rad circuit and UFH manifold tee into a 22mm return within one metre of each other back down to the basement where the boiler is.

The 1st floor rad circuit works great, and electrically all valves/stats etc work as they should. The problem is with the UFH manifold, this has 7 circuits(4 zones) and I'm struggling to get a decent flow or pressure so the UFH pump will feed all the circuits effectively.

I raised the pressure at the fill point in the basement to 1.5bar. At the UFH manifold on the 1st floor it reports just over 1bar which I assume is due to the greater pressure of water in the circuit in the basement.

When I run the UFH on its own (even with just 1 circuit) I seem to be getting reverse flow through the 1st floor rad circuit and the UFH doesn't heat up or very little. Is this because the return from the UFH manifold & 1st floor rad circuit are too close together?

I tried raising the Wilo UFH pump speed (is currently set to 1) but it gives a red/green LED error on the pump. Have bled multiple times also and circuits all pressure tested ok. Also re-flushed to remove any residual air.

Below is a pic of the manifold. In the centre at the bottom is the 22mm feed (flow) from the main boiler circuit in the basement. This tees left to the UFH manifold with zone valve and off to the right with zone valve for the 1st floor rad circuit.

The return from the UFH manifold is on the far left and this goes under the floor where it then tees into the return from the rad circuit before heading back down to the basement return to the boiler.