Hi everyone

Sorry first of all for what might seem like basic questions. Some context first then a few questions at the end...

I am fitting thermostatic shower valve/mixer (link to product) recessed into the wall.

Instructions specify that the ideal pressure is: 0.2Mpa-0.5Mpa

They also state 'standard' pressure: Dynamic water pressure 0.3+-0.02Mpa

My house...

Very standard gravity fed system.

1st floor (which is the top floor) has a hot water cylinder and the same floor the shower will be installed.

Loft has the cold water tank.

I have a Stuart Turner shower pump part number 44419 (link to product and specs etc) to be installed on the first floor, same as the shower and below the water tank which as mentioned is in the loft.

The specs say 1.5bar (0.15Mpa) but of course it depend on the head pressure or other factors which if I am totally honest I really struggle to understand how to figure out the pressure performance curves for pumps.

What I do know is that I already use this pump elsewhere in the house on the same floor and the pressure is very good. The pump uses 15mm pipes in and out for hot and cold. The only difference with this other shower is that its a little further away which needs the pipes to go up into the loft and drop into the other bathroom other side of the house.

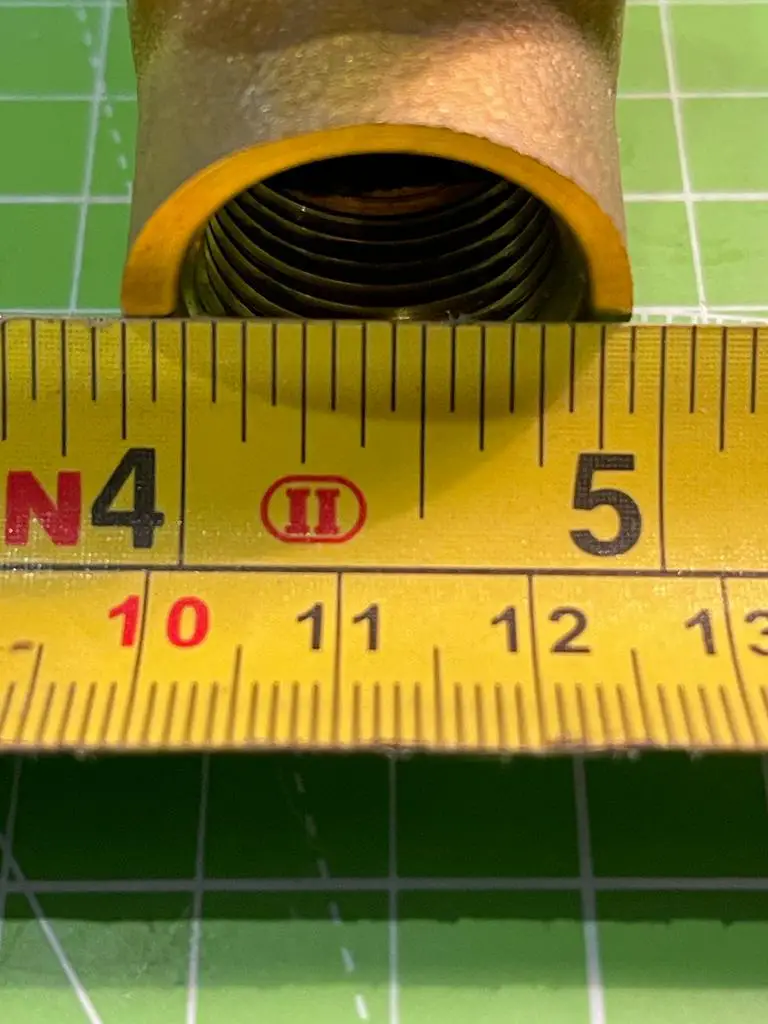

Question 1: can someone first please help double check my measurements:

The shower valve seems to take a 1 inch type feed in for hot and cold.

I seem to struggle to find connections 15mm to 1" which in itself might be telling me something!

See image:

I'm struggling to figure out the connection size for the exit connections (image below) to the shower head and shower hose. Looks larger than 3/4inch but maybe I am not looking at this correctly. can someone help please?

Question 2: Can I feed feed this with 15mm given that the other shower with the same pump fed with 15mm works ok?

Question 3: Can anyone provide a link to a part at SF or TS for fittings that will allow me to use 15mm?

Thank you

Sorry first of all for what might seem like basic questions. Some context first then a few questions at the end...

I am fitting thermostatic shower valve/mixer (link to product) recessed into the wall.

Instructions specify that the ideal pressure is: 0.2Mpa-0.5Mpa

They also state 'standard' pressure: Dynamic water pressure 0.3+-0.02Mpa

My house...

Very standard gravity fed system.

1st floor (which is the top floor) has a hot water cylinder and the same floor the shower will be installed.

Loft has the cold water tank.

I have a Stuart Turner shower pump part number 44419 (link to product and specs etc) to be installed on the first floor, same as the shower and below the water tank which as mentioned is in the loft.

The specs say 1.5bar (0.15Mpa) but of course it depend on the head pressure or other factors which if I am totally honest I really struggle to understand how to figure out the pressure performance curves for pumps.

What I do know is that I already use this pump elsewhere in the house on the same floor and the pressure is very good. The pump uses 15mm pipes in and out for hot and cold. The only difference with this other shower is that its a little further away which needs the pipes to go up into the loft and drop into the other bathroom other side of the house.

Question 1: can someone first please help double check my measurements:

The shower valve seems to take a 1 inch type feed in for hot and cold.

I seem to struggle to find connections 15mm to 1" which in itself might be telling me something!

See image:

I'm struggling to figure out the connection size for the exit connections (image below) to the shower head and shower hose. Looks larger than 3/4inch but maybe I am not looking at this correctly. can someone help please?

Question 2: Can I feed feed this with 15mm given that the other shower with the same pump fed with 15mm works ok?

Question 3: Can anyone provide a link to a part at SF or TS for fittings that will allow me to use 15mm?

Thank you