Hi Guys, Hopefully someone can enlighten me here..

For the last month or so there has been an a horrible gargling / bubbling noise coming from the airing cupboard.

I have isolated this now to be only when the boiler stops calling for heat. What seems to be happening is that the boiler stops the call for heat, the 2 port valve switches to the off position, but the pump continues to run. Thus diverting the flow to the bypass / hot water cylinder (and possibly creating back pressure on the pump). I'm no plumber, but am assuming this shouldn't be happening.

If this is the case, could someone help me understand where the issue is originating from? The 2 port valve seems to be moving on and off freely when the room stat is clicked on and off, so the movement seems to be fine there. Is this more likely a faulty programmer? We have been here 2 years now and the issue has only arisen in the last month or two.

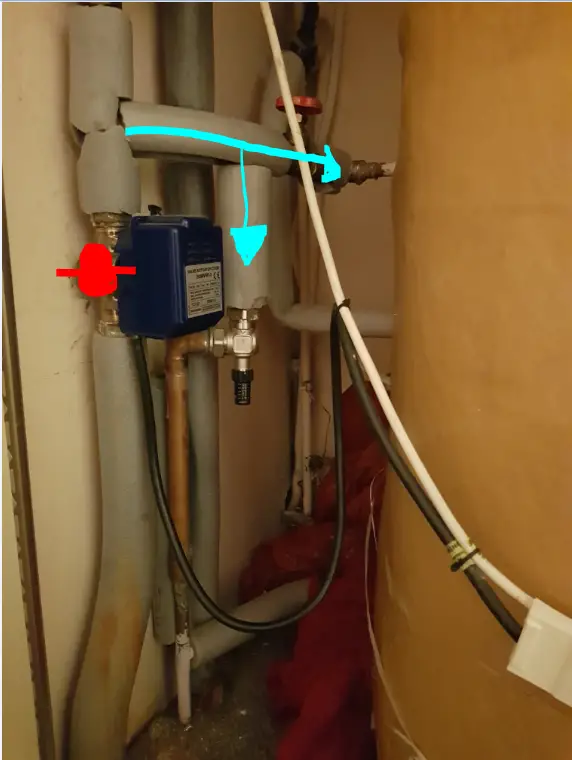

Red in the picture is the 2 port valve switching off.. sky blue is to cylinder / boiler return.

Thanks in advance!

For the last month or so there has been an a horrible gargling / bubbling noise coming from the airing cupboard.

I have isolated this now to be only when the boiler stops calling for heat. What seems to be happening is that the boiler stops the call for heat, the 2 port valve switches to the off position, but the pump continues to run. Thus diverting the flow to the bypass / hot water cylinder (and possibly creating back pressure on the pump). I'm no plumber, but am assuming this shouldn't be happening.

If this is the case, could someone help me understand where the issue is originating from? The 2 port valve seems to be moving on and off freely when the room stat is clicked on and off, so the movement seems to be fine there. Is this more likely a faulty programmer? We have been here 2 years now and the issue has only arisen in the last month or two.

Red in the picture is the 2 port valve switching off.. sky blue is to cylinder / boiler return.

Thanks in advance!