about this time last year I mentioned that my daughters bungalow had a 2 pumped central heating system and that later on in the year it developed a problem i/e water started to overflow fron the exspansion tank in the loft, and that forum readers suggested that it that it was the coil in the cylinder that had gone. Unfortunatley while I was on holiday see called out a plumber!!!! who said that the ball cock was all rusted up and that it needed changing (what a load of rubish) and he fitted a new one. The was that he showed her was a metal one and i know for a fact that the one that was there was a plastic one. And he charged her £75. and that the coil had not gone ( she told him this is what her dad thought). Any how my question now is two fold, as I want to fit a 2 port MV and should i fit it on the flow or return side of the DHW or should it be fitted on the same pipe as the flow ( not sure as to wheter the pump is on the flow or return as it is almost a year since i looked. And finally should the wiring of the mv be in series or parallel with the pump and the cyl stat.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2 pumped system

- Thread starter morrisminor

- Start date

my word that was quick, thanks plan c i new about i just wanted to make sure it was the pipe work that i was not so sure about.What about the pump

it is a 2 pumped system 1 for the DHW & 1 for the CH. Its the DHW 1 that I am concerned about, should this pump be on the flow or the return and can the valve be fitted on the same pipe as the pump and should it be before or after the pump.

pump on the flow valve on the return

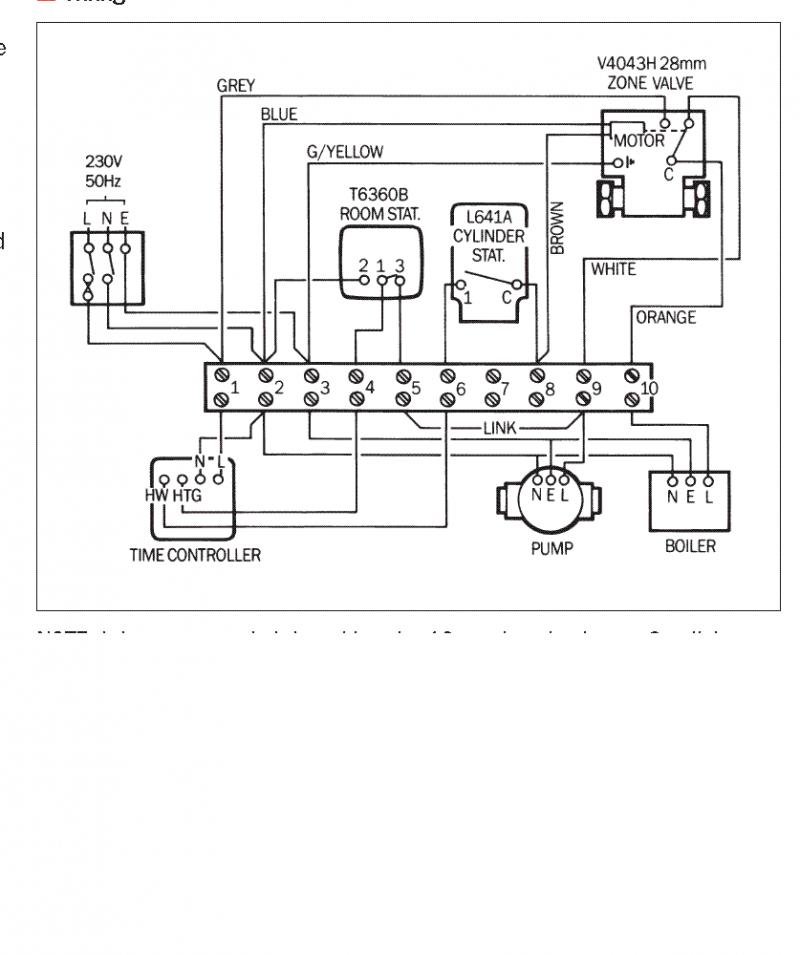

Kev the wiring dgrm that I did for the system is as follows its a honeywell 699 prog 1 & 2 terminals has a fused feed in via a double pole switch, links are 1-5-6 and 3-7. live from boiler & cylinder stat are wired to term 8 and the other side of the cyl stat brings in the DHW pump. Term 3 feeds the CH pump. CH only when selector switch is selected 3 makes contact with 5 3 linked to 7 7 is made to 8 (boiler and pump) DHW only 6makes with 8 (boiler & cyl stat ) which brings in DHW pump Hope all that sence to you all the negs & earth cons are commond

Firstly has the problem with the overflowing tank sorted?

Secondly what is the problem with the system as it is and why do you think adding a zone valve will cure it?

I wouldn't usually recommend just adding a zone, you may have to alter some pipework to make sure it all operates correctly.

If you tell us exactly how the system is piped at the moment (position of pumps in relation to boiler/cylinder tanks etc.) you might get some useful input as to what to do for the best

Secondly what is the problem with the system as it is and why do you think adding a zone valve will cure it?

I wouldn't usually recommend just adding a zone, you may have to alter some pipework to make sure it all operates correctly.

If you tell us exactly how the system is piped at the moment (position of pumps in relation to boiler/cylinder tanks etc.) you might get some useful input as to what to do for the best

1) no, bungallow use to have a coal fire with a back boiler and a pump in the loft to circulate the hw around the place. And in the mid 90's the fire and back boiler was removed and a free standing oil fired boiler installed in the garage some 10 feet away and 6 rads fitted along with and additional pump in the loft on the dhw flow. no themostats of any sort was fitted. during 2004 the garage was converted into a toy room with 2 rads fitted ( fed off the feed from the dhw not the suply to the taps) like a heat sink. at the beging of this year I fitted 5 TRV's and a cylinder stat, the cyl stat controls the dhw pump and the boiler stat controls the ch pump.

2) The dhw pump is about 3 feet from the raised f&e tank in the loft ( pump on the floor of the loft) both the cold water and the f & e tanks are almost directly above the hot water cylinder.

3) The water comes back up the feed pipe at the bottom of the f & e tank (not from the ball cock) and it only happens about 5 to 10 mins after the dhw comes on. I lowered the water in the f & e Tank to about 2" above the outlet at the bottom of the tank, but after a few days the water level rise's and then comes out of the over flow (again only when the dhw is on). I did notice that the pump setting on the dhw was on the max (3) which I have now turned down to 1 and it now takes a few days longer to over flow. I am not sure if all this has happend since I put in the trv's as the bungallow was empty for nearly 8 months while I was doing some work on it for my daughter befor she moved in and only started to happen during the summer and not right away. Both pumps are about 20 feet away from the boiler, the ch pump being about 12 feet away from the boiler and the other one about 20 feet.

2) The dhw pump is about 3 feet from the raised f&e tank in the loft ( pump on the floor of the loft) both the cold water and the f & e tanks are almost directly above the hot water cylinder.

3) The water comes back up the feed pipe at the bottom of the f & e tank (not from the ball cock) and it only happens about 5 to 10 mins after the dhw comes on. I lowered the water in the f & e Tank to about 2" above the outlet at the bottom of the tank, but after a few days the water level rise's and then comes out of the over flow (again only when the dhw is on). I did notice that the pump setting on the dhw was on the max (3) which I have now turned down to 1 and it now takes a few days longer to over flow. I am not sure if all this has happend since I put in the trv's as the bungallow was empty for nearly 8 months while I was doing some work on it for my daughter befor she moved in and only started to happen during the summer and not right away. Both pumps are about 20 feet away from the boiler, the ch pump being about 12 feet away from the boiler and the other one about 20 feet.

I suggest you read TWGas post again and try and resolve the problem before you do anything.

If the header tank is overflowing, where is the water coming from, a simple question, that should be simple to answer.

Is the vent pipe blowing over.

Is the water in the header tank hot.

What is the height of the water in the storage tank compared to the header, which is higher.[/i]

If the header tank is overflowing, where is the water coming from, a simple question, that should be simple to answer.

Is the vent pipe blowing over.

Is the water in the header tank hot.

What is the height of the water in the storage tank compared to the header, which is higher.[/i]

I thought that I made it clear in my last reply!!!! how ever I will make it short this time. No the vent pipe is not blowing over (as you call it) and 2 the water gets hot after about 10 mins. its comming back up the feed pipe at the botton of the f & e tank. the level of the water in the cold water tank is about foot higher to start with and after the dhw start comming back up the pipe the level in the f & e tank rise's by about 6" and the it starts to over flow. What are you calling the header tank, do you mean the one that fill up the dhw cylinder and if so then perhap you should read my last in put on this matter

Ok lets all agree on the terminology.

The header tank fills the heating (primary side) of the system.

The storage tank is what fill the cylinder.

And the cylinder is what holds the hot water.

What is the water level of the header and storage tank in relation to each other, and which is the highest.

When you say the water gets hot after about 1 mins can I assume thats in the header tank.

Where do you suppose all this extra water is coming from, something has to be displaced, with either air or water from another source.

Are the radiators and boiler filling up with air.

Is the storage tank ballvalve running when the header tank is overflowing.

The header tank fills the heating (primary side) of the system.

The storage tank is what fill the cylinder.

And the cylinder is what holds the hot water.

What is the water level of the header and storage tank in relation to each other, and which is the highest.

When you say the water gets hot after about 1 mins can I assume thats in the header tank.

Where do you suppose all this extra water is coming from, something has to be displaced, with either air or water from another source.

Are the radiators and boiler filling up with air.

Is the storage tank ballvalve running when the header tank is overflowing.

saga finally finished at last I hope.

1) turned off gate valve that kept the cylinder topped up i/e the domestic tank ( the big one)

2) emptied the f & e tank to about 2" above the out let at the bottom of the tank and just before the operation of the ball cock came into play.

3) operated the selector switch to hot water and whent back up into the loft and the water came up into the bottom of the f & E tank and it was scalding hot. the level did not rise in the big tank or drop.

4) returned the selector switch to off and checked cylinder stat and boiler settings .

5) cyl stat was set at 80 c and boiler set on max (84c)

6) set cyl stat to 60c and boiler to medium (180c)

recommenced the proceder and all seem to be working ok now!!.

Before I started this proceder today I noticed that the pump on the domestic side of the system was stuck ( not working) and that a rusty coloured water had been dripping onto the boil cock in the f & e tank from the vent pipe above it. I used an irish spanner to tap it ( Hammer) and gave it a try and all was well. I do keep a spur pump just in case one packs up I have asked my daughter tokeep an eye open for the over flowing. It would seem I hope that it was exspansion + sticking pump + system to hot.!! or am i just opening that I have cured it. O by the way I did not fit the mv valve.

I have asked my daughter tokeep an eye open for the over flowing. It would seem I hope that it was exspansion + sticking pump + system to hot.!! or am i just opening that I have cured it. O by the way I did not fit the mv valve.

what is a happy temp for a boiler to run and a cyl stat be set at

1) turned off gate valve that kept the cylinder topped up i/e the domestic tank ( the big one)

2) emptied the f & e tank to about 2" above the out let at the bottom of the tank and just before the operation of the ball cock came into play.

3) operated the selector switch to hot water and whent back up into the loft and the water came up into the bottom of the f & E tank and it was scalding hot. the level did not rise in the big tank or drop.

4) returned the selector switch to off and checked cylinder stat and boiler settings .

5) cyl stat was set at 80 c and boiler set on max (84c)

6) set cyl stat to 60c and boiler to medium (180c)

recommenced the proceder and all seem to be working ok now!!.

Before I started this proceder today I noticed that the pump on the domestic side of the system was stuck ( not working) and that a rusty coloured water had been dripping onto the boil cock in the f & e tank from the vent pipe above it. I used an irish spanner to tap it ( Hammer) and gave it a try and all was well. I do keep a spur pump just in case one packs up

what is a happy temp for a boiler to run and a cyl stat be set at

C

cmother1

This system sound like a complete lash-up to me. I really think I'd investigate and draw up a plan of it as it stands with a view to making it a bit more conventional. A Cambridge maths graduate friend of mine tried to put in a 2 pump system (because he had 2 pumps going spare) and never got it to work properly. Serves the smart a*se right!

I know its been said on here befor some councils adopted this system years ago when they changed over from a coal fired back boilers with a pumped system to a free standing either wall or floor mounted boilers. I have spoken to many plumbers that had come accross this system in the past, not had much of a problem with it. Their comments were they only had problems when DIY'ers think that they could do a job them selves and it was realy out of their league. Not all DIY'ers know what they are doing ( 3 amp fuse blows so fit a 5 amp that blows fit a 13 if that blows wrappit in silver paper). Instead of finding what was causing the fuse to blow in the first place. This is one of the reasons that if I am about to do something that I am not sure about I will become a pain in the butt and ask what to the professionals is a stuppid question, and I will ask as many people as possible to see how varied the answers are befor I proceed with any thing. I spent nearly 40 years as a post office telephone engineer and came accross many lash up jobs by people thing that they could fix a telephone or install a phone. Now a days it easy just plug it in and if it don't work try another phone. I worked on strowger & txe's as well as pmbx's and climb many a pole. It was a so called plumber that told me to fit the mv in the pipe run and a none return valve in the feed pipe at the bottom of the f & e tank. Some one earlier in thios debate said that I should check out the cause rather than shift to somewere else. That advice I took ( the fuse syndrome comes into mind). I would like to thank all those out there for their input to my dilemma. And now back to my project of restoring classic cars. its suprising the amount of knowledge that you can get on the various forum sights .

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 62

- Views

- 30K

- Replies

- 25

- Views

- 5K

- Replies

- 1

- Views

- 768