Went outside “just to unblock the front downpipe” – thinking 30 min max job, hasn’t worked out like that ……

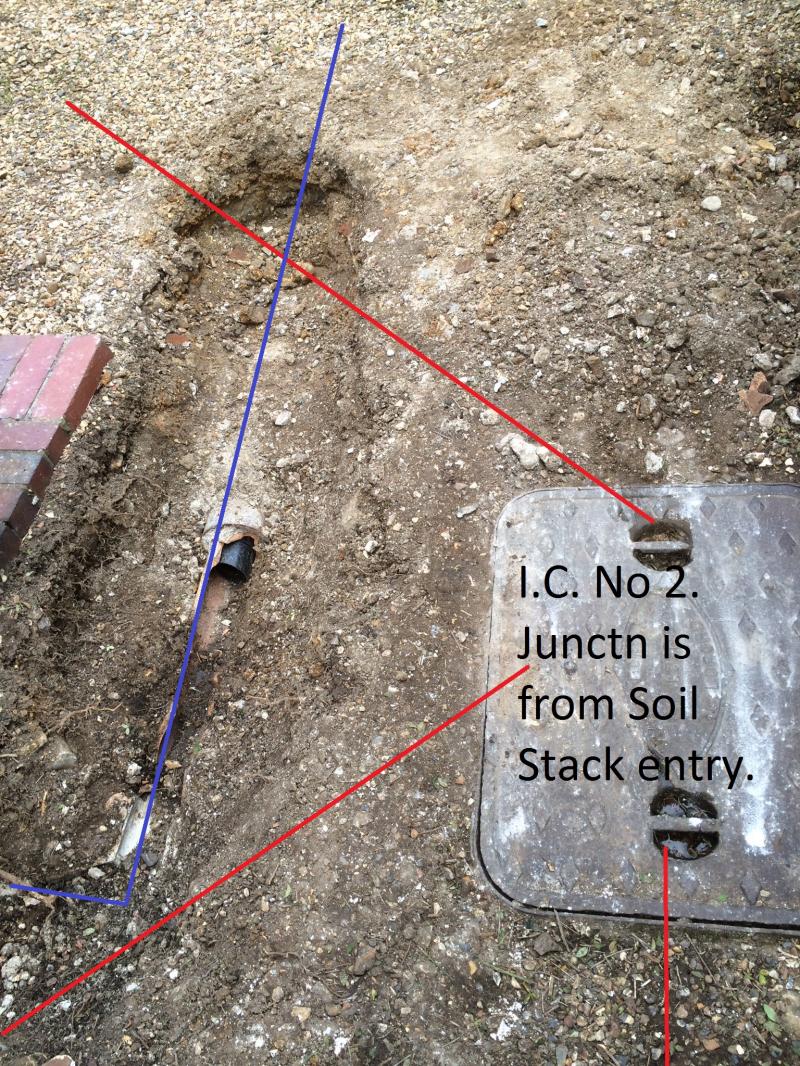

I’ve removed the hedge from the side of the house, removed edging set in who knows how much concrete and dug out PVC 68mm downpipe and Clay Pipe that was also covered in lots and lots a concrete. All right up against side of house and porch floor and running between a soil inspection chamber.

Discovered two air vents that were buried to half height at the side of the house too.

Now I’ve got a nice excavation at the side of the house, missing section of down pipe and section of clay run, remaining clay with up to 2.5” of concrete on top of it, which could continue full length. I have ideas but also questions as to how to best fix this.

1. Top of the list is, can I connect 110mm underground drainage pipe to what appears to be 3” clay? The clay diameter seems to be 3” inside and 4” outside. Plenty of those Fernco type connectors around for 4” to 4” but what do I do in this situation?

2. Initially, after clearing the first lot of roots out, our feeble 7.2 lpm hose lasted 5 minutes before backing the run up. Now having rodded and removed more roots and cleared for 4.5metres I’ve run it for 1 hour, which I calculate is 432 litres and it was still going. Will that give this a chance of working adequately? It covers approx. 8M x 6M foot print front and side roof elevations of a 3 Bedroom Semi.

3. There is obviously a decent amount of silt and sludge at the end of the run which a screw on a rod won’t pull out. Is there anything else I can do or worth doing to clear further – worth paying for a drain clearer with some equipment other than drain rods?

The first preference I initially came up with, to fix the pipe run properly, was to run new 110mm pipe out to this soakaway full length but my assessment now is that is going to be a major headache.

4. My second option was to connect the down pipe (via a gully trap) at ground level or below across to the Soil Pipe about 3m away to the left. Is that allowed on a dual system. Would it impede the soil pipe serving the upstairs bathroom?

· The house is 1920s.

· The draninage is already dual use, at other downpipe positions, the down pipe enters chambers mixed with foul water.

The end of the drain rods in the pictures shows where I have cleared to.

Thanks for the help.

I’ve removed the hedge from the side of the house, removed edging set in who knows how much concrete and dug out PVC 68mm downpipe and Clay Pipe that was also covered in lots and lots a concrete. All right up against side of house and porch floor and running between a soil inspection chamber.

Discovered two air vents that were buried to half height at the side of the house too.

Now I’ve got a nice excavation at the side of the house, missing section of down pipe and section of clay run, remaining clay with up to 2.5” of concrete on top of it, which could continue full length. I have ideas but also questions as to how to best fix this.

1. Top of the list is, can I connect 110mm underground drainage pipe to what appears to be 3” clay? The clay diameter seems to be 3” inside and 4” outside. Plenty of those Fernco type connectors around for 4” to 4” but what do I do in this situation?

2. Initially, after clearing the first lot of roots out, our feeble 7.2 lpm hose lasted 5 minutes before backing the run up. Now having rodded and removed more roots and cleared for 4.5metres I’ve run it for 1 hour, which I calculate is 432 litres and it was still going. Will that give this a chance of working adequately? It covers approx. 8M x 6M foot print front and side roof elevations of a 3 Bedroom Semi.

3. There is obviously a decent amount of silt and sludge at the end of the run which a screw on a rod won’t pull out. Is there anything else I can do or worth doing to clear further – worth paying for a drain clearer with some equipment other than drain rods?

The first preference I initially came up with, to fix the pipe run properly, was to run new 110mm pipe out to this soakaway full length but my assessment now is that is going to be a major headache.

4. My second option was to connect the down pipe (via a gully trap) at ground level or below across to the Soil Pipe about 3m away to the left. Is that allowed on a dual system. Would it impede the soil pipe serving the upstairs bathroom?

· The house is 1920s.

· The draninage is already dual use, at other downpipe positions, the down pipe enters chambers mixed with foul water.

The end of the drain rods in the pictures shows where I have cleared to.

Thanks for the help.